Electronic Shielding Rubber in Satellite Communication Equipment

2025/06/16

0

1. Introduction

In the realm of satellite communication, where the transmission and reception of high – frequency signals are essential for global communication, navigation, and data transfer, the integrity and quality of signals are of utmost importance. Electronic shielding rubber has emerged as a key component in satellite communication equipment, providing effective protection against electromagnetic interference (EMI) and radio – frequency interference (RFI). This interference can disrupt signal transmission, degrade communication quality, and even cause system failures.

2. Properties of Electronic Shielding Rubber

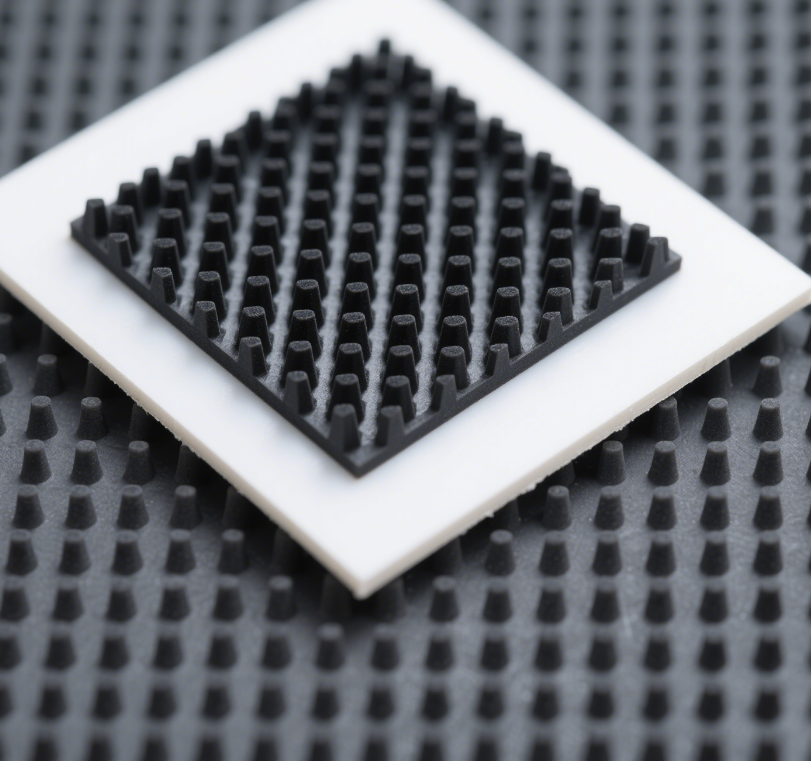

2.1 Conductivity

One of the primary properties of electronic shielding rubber is its conductivity. It is typically formulated with conductive fillers such as carbon black, metal powders (e.g., silver, nickel, copper), or metal fibers dispersed in a rubber matrix. These conductive fillers form a continuous conductive network within the rubber, allowing it to act as a Faraday cage. The conductivity of the shielding rubber determines its effectiveness in blocking electromagnetic waves. Higher conductivity means better shielding performance, as it can more efficiently redirect and absorb interfering electromagnetic fields.

2.2 Elasticity and Flexibility

Satellite communication equipment often consists of complex shapes and components that may need to move or vibrate during operation. Electronic shielding rubber retains excellent elasticity and flexibility, enabling it to conform to irregular surfaces and maintain a tight seal even under mechanical stress. This property is crucial for ensuring continuous shielding performance, as any gaps or cracks in the shielding can compromise its effectiveness. The rubber can withstand repeated flexing, compression, and extension without losing its shielding capabilities or mechanical integrity.

2.3 Chemical Resistance

Satellites operate in harsh space environments that expose the equipment to various chemical substances, including atomic oxygen, ultraviolet radiation, and extreme temperature fluctuations. Electronic shielding rubber is designed to have high chemical resistance to these environmental factors. Specialized rubber polymers, such as fluorosilicone or ethylene – propylene – diene – monomer (EPDM) with appropriate additives, are used to enhance the rubber’s resistance to degradation. This ensures that the shielding rubber can maintain its performance over the long lifespan of the satellite, which can range from several years to decades.

3. Functions in Satellite Communication Equipment

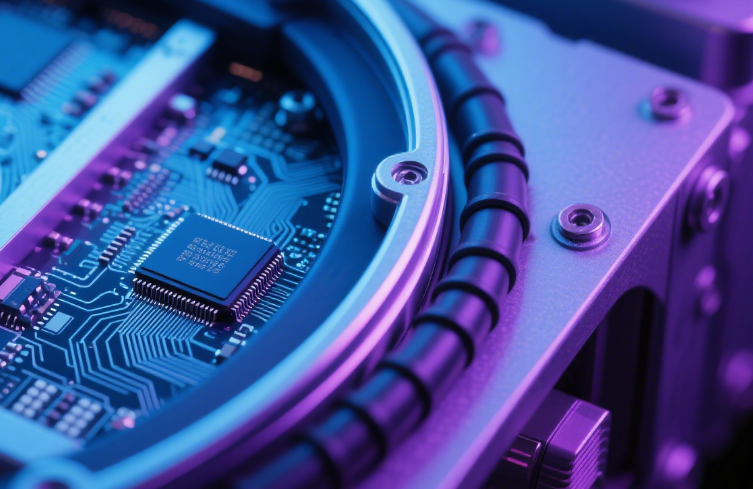

3.1 EMI/RFI Shielding

The main function of electronic shielding rubber in satellite communication equipment is to shield against EMI and RFI. Electromagnetic waves from various sources, both internal (such as other electronic components within the satellite) and external (e.g., terrestrial communication signals, solar flares), can interfere with the delicate satellite communication systems. The shielding rubber creates a barrier that reflects, absorbs, and dissipates these interfering electromagnetic fields, preventing them from reaching sensitive electronic components like receivers, transmitters, and signal processors. By effectively blocking EMI/RFI, the shielding rubber helps to ensure the accurate and reliable transmission and reception of satellite communication signals.

3.2 Environmental Sealing

In addition to electromagnetic shielding, electronic shielding rubber also provides environmental sealing. It prevents the ingress of dust, moisture, and other contaminants into the satellite communication equipment. In the vacuum of space, even minute amounts of moisture or particulate matter can cause serious problems, such as corrosion of electrical contacts, short – circuits, or degradation of insulation materials. The rubber forms a tight seal around connectors, enclosures, and other interfaces, protecting the internal components from the harsh space environment and maintaining their operational reliability.

3.3 Vibration Damping

Satellites experience mechanical vibrations during launch and operation. These vibrations can cause damage to the delicate electronic components within the communication equipment. Electronic shielding rubber, due to its elastic nature, acts as a vibration – damping material. It absorbs and dissipates the mechanical energy generated by vibrations, reducing the amplitude of vibrations transmitted to the electronic components. This helps to protect the components from mechanical stress and potential damage, ensuring the long – term stability and performance of the satellite communication system.

4. Applications in Satellite Communication Equipment

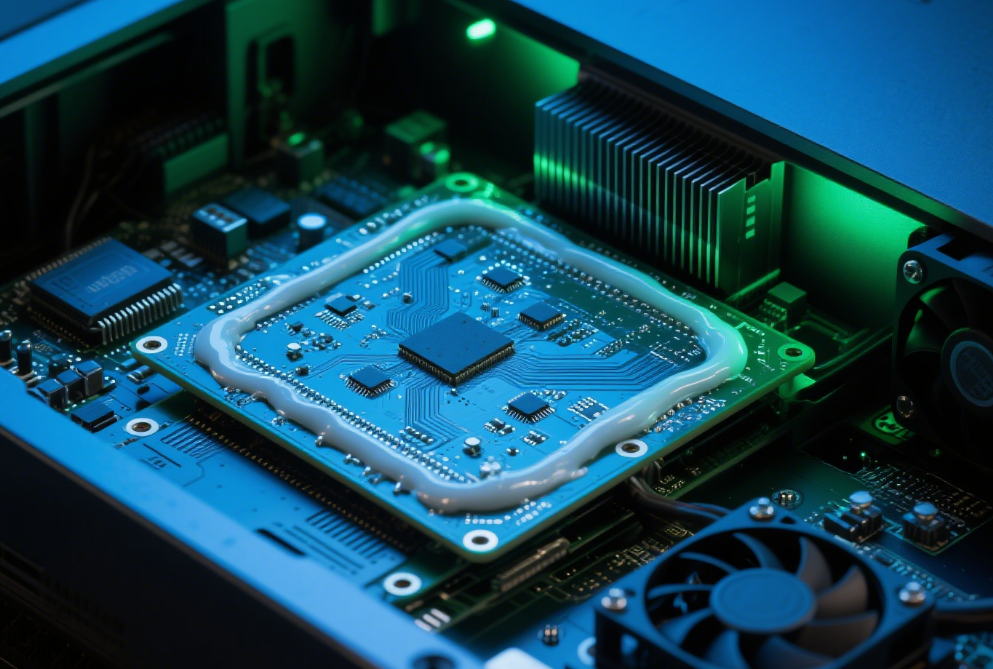

4.1 Enclosure Sealing

The enclosures of satellite communication devices, such as transponders, receivers, and power supplies, are sealed using electronic shielding rubber gaskets. These gaskets are placed between the enclosure halves or around the access ports to create an electromagnetic – tight and environmental seal. They prevent EMI from entering or escaping the enclosure, while also protecting the internal components from the space environment. The gaskets can be custom – designed to fit the specific shape and dimensions of the enclosures, ensuring a precise and effective seal.

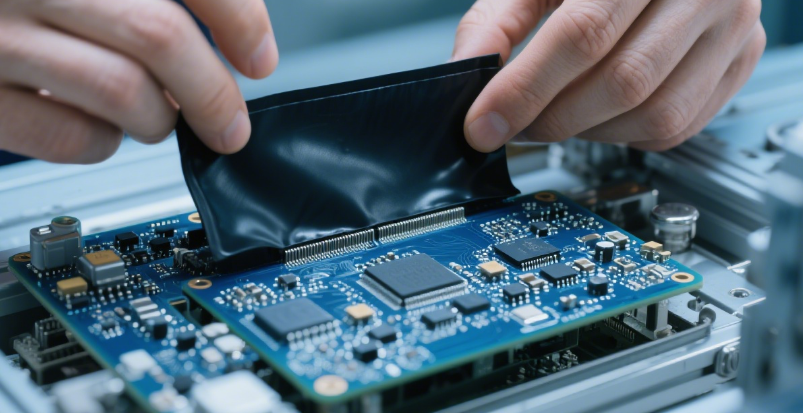

4.2 Connector Sealing

Connectors are critical interfaces in satellite communication equipment for signal and power transmission. Electronic shielding rubber is used to seal connectors, providing both electromagnetic shielding and environmental protection. Shielding rubber grommets or boots are placed around the connectors to prevent EMI leakage and to keep out dust, moisture, and other contaminants. This ensures reliable electrical connections and prevents signal degradation due to interference or environmental factors.

4.3 Cable Shielding

Satellite communication systems use a large number of cables for signal and power distribution. Electronic shielding rubber can be used as a jacket or coating for these cables to provide electromagnetic shielding. The conductive rubber jacket surrounds the cable conductors, preventing electromagnetic fields from coupling into or out of the cables. This helps to maintain the integrity of the signals transmitted through the cables and reduces the risk of interference with other components in the satellite communication system.

5. Future Developments

As satellite communication technology continues to evolve, with the increasing demand for higher data rates, more complex communication systems, and longer – lasting satellites, the requirements for electronic shielding rubber will also become more stringent. Future research and development efforts are likely to focus on improving the shielding performance of the rubber at higher frequencies, reducing its weight (to minimize the overall weight of the satellite), and enhancing its resistance to even more extreme space environments. New materials and manufacturing techniques may be explored to create more efficient and reliable electronic shielding rubber products for the next generation of satellite communication equipment.