The Application of Food-Grade Silicone Sealants in Equipment

2025/06/24

0

In the field of food production, the sealing performance of equipment is directly related to food safety and production efficiency. As a special industrial material, food-grade sealant has been widely used in food processing equipment because it complies with food safety standards, can effectively prevent food pollution, and has good sealing and weather resistance. Among them, food-grade silicone sealant stands out due to its unique advantages.

Characteristics of Food-Grade Silicone Sealant

The core feature of food-grade silicone sealant lies in the combination of its safety and excellent performance. Such sealants strictly follow relevant food safety regulations and standards, such as the 21 CFR 177.2600 standard of the U.S. Food and Drug Administration (FDA) and China’s GB 4806 series of national food safety standards. This ensures that no harmful substances are released during contact with food, and no adverse effects are exerted on the flavor, color, and safety of food.

In terms of physical and chemical properties, food-grade silicone sealant demonstrates significant advantages. It has excellent temperature resistance, capable of maintaining stable performance in the temperature range of -40°C to 200°C or even higher. Whether in low-temperature refrigeration equipment or high-temperature sterilization equipment, it can reliably achieve sealing. Meanwhile, it has excellent resistance to common food processing media such as water, oil, acids, and alkalis, and will not swell, corrode, or deteriorate due to contact with these substances, ensuring the long-term effectiveness and stability of the seal. In addition, its good flexibility and elasticity enable it to adapt to slight displacements of equipment caused by factors such as temperature changes and mechanical vibrations, always maintaining a tight seal. Moreover, silicone materials have good electrical insulation and anti-aging properties, further extending the service life of the sealant.

Applications of Food-Grade Silicone Sealant in Different Equipment

Food-grade silicone sealant is widely used in food processing machinery. For example, in equipment such as mixers and grinders, the sealant is used to seal parts like mixing shafts and bearings to prevent food materials from leaking and external impurities from entering, ensuring the normal operation of the equipment and the hygiene and safety of food. In filling machines, the sealant is used for sealing key components such as filling heads and valves to ensure filling accuracy, prevent dripping of liquid food, and avoid product waste and production environment pollution.

Take the chopper commonly used in the meat processing industry as an example. During the high-speed operation of the chopper, good sealing is required between the blades and the cavity to prevent meat filling from splashing and external bacteria from entering. With its excellent temperature resistance, flexibility, and anti-aging properties, food-grade silicone sealant can closely fill the gaps between the blades and the cavity, forming a reliable sealing layer without chemically reacting with the meat filling, thus ensuring the quality and hygiene of the meat filling.

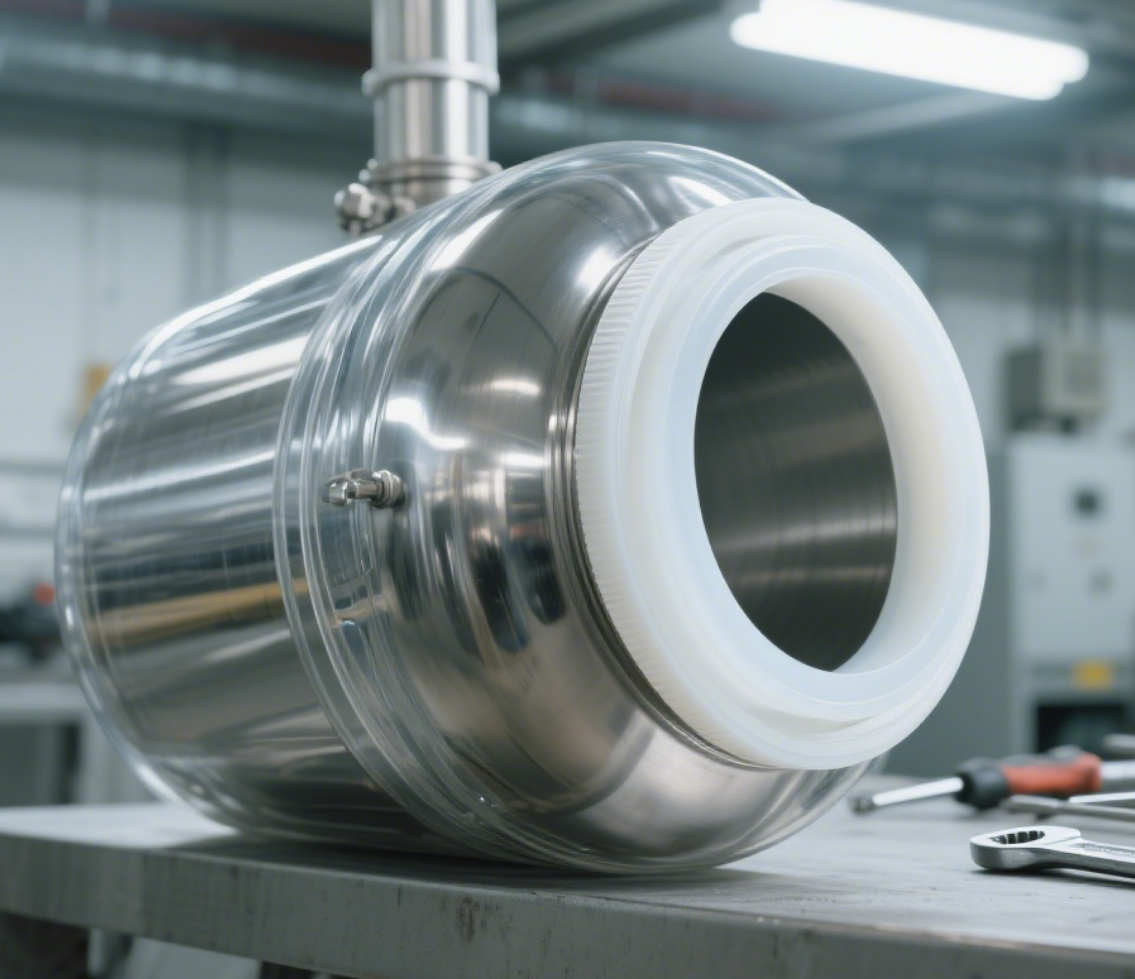

For food storage equipment such as storage tanks and cold storage, food-grade silicone sealant is also indispensable. In storage tanks, the sealant is used for sealing parts such as tank covers and pipeline interfaces to prevent food from being contaminated by external air, moisture, and microorganisms during storage, ensuring food freshness and shelf life. In cold storage, the sealant is used to seal cold storage doors, refrigeration pipes, etc., to prevent cold air leakage, improve the refrigeration efficiency of the cold storage, and reduce energy consumption.

Food-grade silicone sealant is also essential for food conveying equipment such as conveyor belts and pipelines. In the conveyor belt system, the sealant is used to seal conveyor belt joints and equipment connections to prevent food debris from falling and external impurities from mixing in, ensuring the hygiene and safety of the conveying process. In food conveying pipelines, the sealant is used for sealing pipeline interfaces, valves, etc., to prevent food materials from leaking and pipelines from being blocked, ensuring the smooth operation of the conveying system.

Application Advantages of Food-Grade Silicone Sealant

Using food-grade silicone sealant brings multiple advantages to food production equipment. From the perspective of food safety, it can effectively prevent food pollution, avoid problems such as microbial growth and foreign matter mixing caused by poor sealing, and protect consumers’ health. In terms of production efficiency, good sealing performance reduces equipment failures and downtime for maintenance, minimizes waste caused by material leakage, and improves production efficiency and economic benefits. In addition, the long service life and good weather resistance of food-grade silicone sealant reduce the replacement frequency of sealing materials and lower maintenance costs. Meanwhile, its non-toxic, odorless, and mold-resistant properties also meet the strict requirements of the food industry for clean production.

Selection and Usage Precautions for Food-Grade Silicone Sealant

When selecting food-grade silicone sealant, comprehensive consideration should be given to factors such as the equipment’s working environment, contact media, temperature, and pressure. Different types of food-grade silicone sealants have different performance focuses. For example, neutral-curing silicone sealants are suitable for food processing scenarios sensitive to pH values; while oxime-curing silicone sealants, although fast-curing, may produce slight odors and need to be used with caution in food production links sensitive to odors. At the same time, it is necessary to ensure that the selected sealant has passed relevant food safety certifications, such as FDA certification and NSF certification.

When using food-grade silicone sealant, strict compliance with the product manual is required. First, the sealing part needs to be cleaned and dried to remove oil, impurities, and moisture, ensuring good adhesion between the sealant and the sealing surface. Second, the application thickness and dosage of the sealant should be controlled to avoid affecting the sealing effect due to excessive or insufficient use. During the curing process of the sealant, the sealing part should be prevented from being disturbed by external forces or contacting media to ensure that the sealant can fully cure and form a reliable sealing layer. For special application scenarios such as high-temperature and high-pressure environments, attention should also be paid to selecting silicone sealant products with corresponding performance indicators and conducting necessary performance tests.

In conclusion, food-grade silicone sealant plays a vital role in food production equipment. With the continuous improvement of the food industry’s requirements for food safety and production efficiency, the application of food-grade silicone sealant will become more widespread, and its performance will continue to be optimized and innovated, providing strong support for the development of the food industry.