Technical Application Scheme of Thermal Conductive Silicone Sheet for High-power Lamps

- Heat Dissipation Principle and Requirements of High-power Lamps

(1) Heat Dissipation Principle

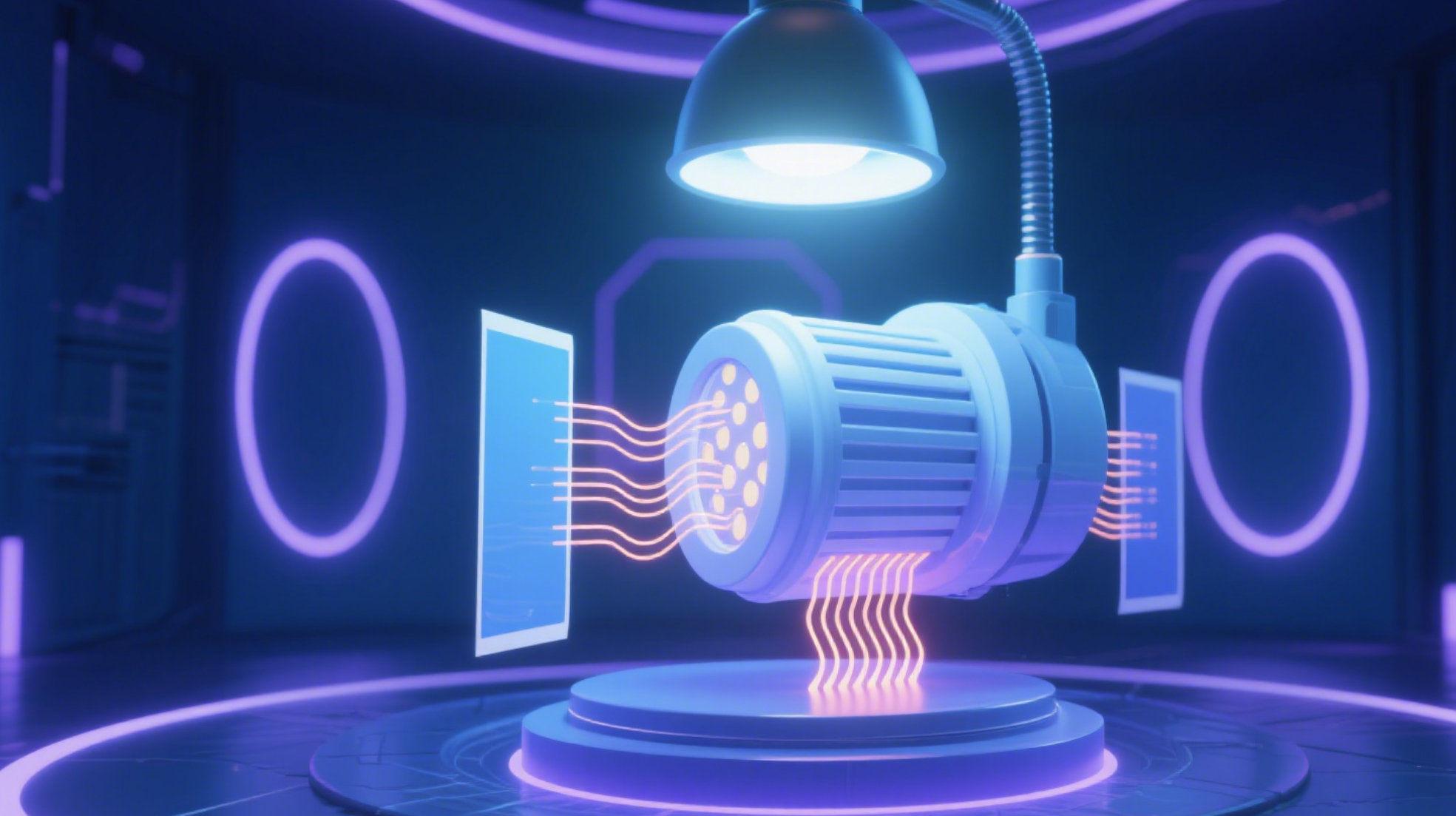

When high-power lamps work, while electrical energy is converted into light energy, a large amount of heat is generated. These heats mainly come from key components such as LED chips and driving power supplies. Heat transfer follows three basic modes: thermal conduction, thermal convection and thermal radiation. Inside the lamp, heat is first transferred from the heat-generating components to the substrate or heat sink in contact with them through thermal conduction; then, through thermal convection, the heat is carried away by the air; finally, part of the heat is dissipated into the surrounding environment in the thermal radiation form. Among them, thermal conduction is the key link of heat transfer inside the lamp, and the thermal conductive silicone sheet plays an important role in optimizing the interface contact and reducing the thermal resistance in the thermal conduction path.

(2) Heat Dissipation Requirements

High heat dissipation efficiency: High-power lamps generate a large amount of heat, and efficient heat dissipation methods are required to quickly export the heat to maintain all components inside the lamp within a suitable operating temperature range. For example, for high-power LED lamps above 100W, it is required to transfer a large amount of heat generated by the chip to the heat sink and dissipate it in a short time to avoid the decrease of luminous efficiency and the shortening of service life caused by the too high chip temperature.

Good electrical insulation performance: There are high-voltage components inside the lamp. To ensure safe use, the heat dissipation material must have reliable electrical insulation performance to prevent electrical short-circuit and other failures caused by the heat dissipation material. The thermal conductive silicone sheet used between the driving power supply and the heat sink needs to be able to withstand a certain working voltage to ensure electrical isolation.

Reliability and stability: Lamps usually need to operate stably for a long time. The heat dissipation material should be able to maintain stable performance under different environmental conditions (such as temperature and humidity changes), and there should be no problems such as aging and performance degradation due to long-term use. For example, in outdoor lamps, the thermal conductive silicone sheet should be able to adapt to the temperature difference between day and night, the temperature changes in the four seasons and the humid environment.

III. Technical Characteristics of Thermal Conductive Silicone Sheet

(1) Thermal Conductivity

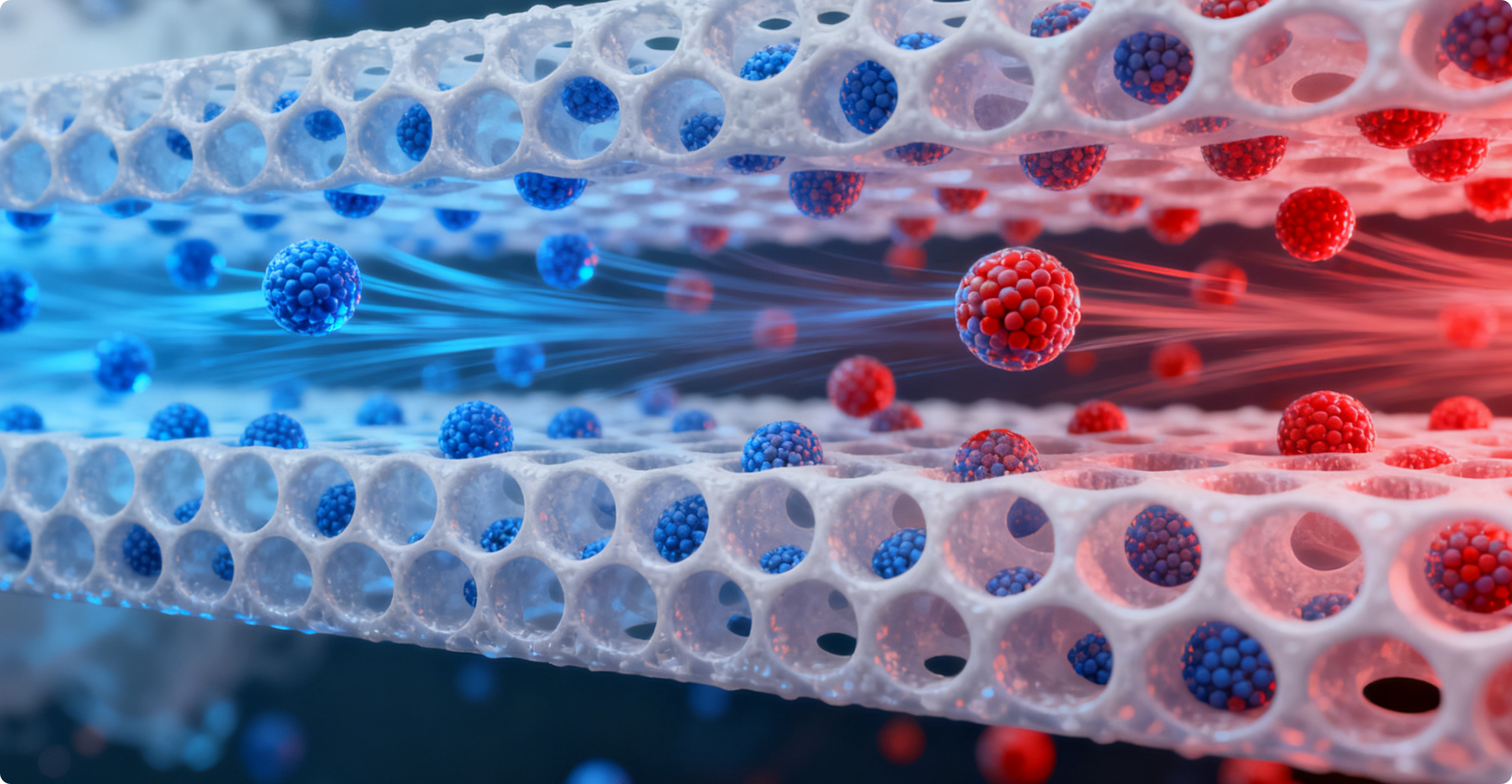

Thermal conductivity coefficient: The thermal conductivity coefficient is a key indicator for measuring the thermal conductivity performance of the thermal conductive silicone sheet, with the unit of W/(m·K). It represents the heat conducted by the material with a unit area and unit thickness under a unit temperature gradient within a unit time. The higher the thermal conductivity coefficient, the faster and more efficient the heat conduction of the thermal conductive silicone sheet. For high-power lamps, to achieve rapid heat dissipation, it is usually necessary to select a thermal conductive silicone sheet with a thermal conductivity coefficient above 3.0W/(m·K). For example, the thermal conductivity coefficient of some high-performance thermal conductive silicone sheets can reach 5.0W/(m·K) or even higher, which can effectively improve the heat dissipation efficiency of the lamp.

Thermal resistance: Thermal resistance refers to the resistance encountered when heat passes through the thermal conductive silicone sheet, with the unit of K/W. The smaller the thermal resistance, the smoother the heat transfer. The thermal resistance of the thermal conductive silicone sheet is related to the characteristics of the material itself, the thickness, and the state of the contact interface. In practical applications, it is necessary to try to select a thermal conductive silicone sheet with low thermal resistance, and optimize the installation process to ensure that the thermal conductive silicone sheet is closely attached to the heat-generating component and the heat sink, further reducing the contact thermal resistance. For example, through special treatment of the surface of the thermal conductive silicone sheet, the contact thermal resistance with the metal surface can be reduced to below 0.1K·cm²/W.

(2) Physical Characteristics

Thickness: The thickness range of the thermal conductive silicone sheet is generally between 0.5 – 5mm. Theoretically, the thinner the thermal conductive silicone sheet, the smaller the thermal resistance and the better the thermal conductivity effect, because the heat transfer path in a thinner material is shorter. However, in practical applications, it is necessary to consider the size of the gap between the heat-generating element and the heat sink inside the lamp. If the gap is large, choosing an overly thin thermal conductive silicone sheet may not be able to effectively fill the gap, resulting in poor heat dissipation effect; if the gap is small, choosing an overly thick thermal conductive silicone sheet may increase the unnecessary thermal resistance. Usually, when the gap is 1mm, a thermal conductive silicone sheet with a thickness of 1.2 – 1.5mm can be selected, which can be moderately compressed after installation to fully fill the gap and achieve the best thermal conduction.

Softness and hardness: The softness determines whether the thermal conductive silicone sheet can be closely attached to the surface of the heat-generating element and the heat sink, effectively filling the tiny gaps and reducing the contact thermal resistance. The softness is generally measured by the Shore hardness. For most applications of high-power lamps, it is recommended to select a thermal conductive silicone sheet with a Shore hardness between Shore 00 20 – Shore 00 60. For example, between the LED chip and the heat dissipation substrate, a thermal conductive silicone sheet with good softness can closely wrap the chip like plasticine to ensure uniform and rapid heat transfer. If the surface flatness of the lamp components is poor, a product with lower hardness can be selected to better adapt to the irregular surface.

Compression characteristics: The thermal conductive silicone sheet will be compressed under a certain pressure during the installation process. Good compression characteristics are manifested in that within a certain pressure range, the thermal conductive silicone sheet can be moderately compressed to fill the gap, and can maintain a certain compression deformation after the pressure is removed to maintain a tight contact state. For example, the compression rate of some thermal conductive silicone sheets can reach 30% – 50%. During the long-term use of the lamp, even if affected by factors such as vibration, it can still maintain good thermal contact.

(3) Electrical Performance

Insulation performance: The thermal conductive silicone sheet needs to have reliable insulation performance to prevent short circuits between components with different potentials and ensure the electrical safety of the lamp. The insulation performance is usually measured by the breakdown voltage and volume resistivity. The breakdown voltage refers to the voltage value when the material breaks down under the specified test conditions, with the unit of kV/mm; the volume resistivity refers to the resistance value per unit volume of the material, with the unit of Ω·m. Generally, the breakdown voltage requirement for the thermal conductive silicone sheet in electronic equipment is between 5 – 15kV/mm, and the volume resistivity requirement is between 10^12 – 10^15Ω·m. Between the high-voltage components such as the driving power supply and the heat sink in high-power lamps, a thermal conductive silicone sheet with good insulation performance must be used to ensure the safe and stable operation of the equipment in a high-voltage environment.

Electrostatic discharge performance: In some application scenarios of lamps that are sensitive to static electricity, the thermal conductive silicone sheet should also have a certain electrostatic discharge performance to prevent damage to the electronic components inside the lamp caused by static electricity accumulation. For example, some thermal conductive silicone sheets added with special conductive fillers can quickly export static electricity to avoid the influence of static electricity on precision components such as LED chips.

(4) Chemical Stability and Flame Retardancy

Chemical stability: The thermal conductive silicone sheet should have good chemical stability and will not react chemically with surrounding materials such as metals and plastics during the operation of the lamp, resulting in material performance degradation. At the same time, it should be able to resist certain chemical corrosion. For example, for lamps used in industrial environments with corrosive gases, the thermal conductive silicone sheet needs to be able to maintain stable performance. For example, the thermal conductive silicone sheet designed with a special formula can be used for a long time without performance changes in an environment containing a small amount of acidic or alkaline gases.

Flame retardancy: For high-power lamps, especially those used in places with high safety requirements (such as shopping malls, schools, hospitals, etc.), the flame retardancy of the thermal conductive silicone sheet is crucial. The flame retardancy can prevent the thermal conductive silicone sheet from burning when encountering a fire source and avoid the occurrence of a fire. It is usually measured by the flame retardant grade, and common flame retardant grade standards include UL94, etc. In the UL94 standard, the V – 0 grade is the highest flame retardant grade, indicating that the material can quickly self-extinguish under the specified test conditions, and the drips will not ignite the absorbent cotton. For lamps used in these places, a thermal conductive silicone sheet with a flame retardant grade reaching UL94 V – 0 must be selected to ensure safety in extreme situations.

- Key Points of Selecting Thermal Conductive Silicone Sheet

(1) Selection According to the Lamp Power and Heat Generation Requirements

High-power lamps: For high-power lamps with a power above 100W, due to the large amount of heat they generate and high heat dissipation requirements, it is necessary to preferentially select a thermal conductive silicone sheet with high thermal conductivity (such as 5.0W/(m·K) or above) and low thermal resistance. At the same time, considering the compact internal structure of the lamp and the possible complex installation space, it is necessary to select a product with good softness, moderate thickness and good compression characteristics to ensure that the gap can be fully filled and efficient heat dissipation can be achieved. For example, for high-power floodlights used in large sports venues, a thermal conductive silicone sheet with a thickness of 1.5mm, a thermal conductivity coefficient of 5.5W/(m·K) and a Shore hardness of Shore 00 30 can be selected.

Medium-power lamps: For medium-power lamps with a power between 50 – 100W, a thermal conductive silicone sheet with a thermal conductivity coefficient between 3.0 – 5.0W/(m·K) can be selected. In terms of thickness selection, according to the gap inside the lamp, a product with a thickness of 1.0 – 2.0mm can generally be selected. At the same time, it is necessary to pay attention to its insulation performance and chemical stability to meet the long-term stable operation requirements of the lamp. For example, in some medium-power LED track lights used in commercial lighting, a thermal conductive silicone sheet with a thickness of 1.2mm, a thermal conductivity coefficient of 4.0W/(m·K) and a breakdown voltage of 8kV/mm can be selected.

(2) Consideration of the Lamp Working Environment

Temperature environment: If the lamp works in a high-temperature environment (such as lighting lamps near industrial furnaces), the thermal conductive silicone sheet needs to have good high-temperature resistance performance and be able to maintain stable thermal conductivity performance and physical characteristics at high temperatures. Generally, a product with a temperature resistance range above 150℃ can be selected. On the contrary, in a low-temperature environment (such as lighting lamps in cold storage), the thermal conductive silicone sheet should be able to maintain softness and flexibility at low temperatures to ensure good thermal contact, and a product with good low-temperature performance can be selected, and its lower temperature resistance limit can reach – 40℃ or even lower.

Humidity environment: For lamps used in a humid environment (such as outdoor landscape lighting lamps, bathroom lighting lamps, etc.), the thermal conductive silicone sheet should have good moisture resistance performance and chemical stability to prevent the performance degradation of the material or corrosion caused by the intrusion of moisture. A thermal conductive silicone sheet with moisture-proof treatment and low water absorption can be selected, and its insulation performance can still meet the safety requirements in a humid environment.

Special environment: For lamps used in special environments with corrosive gases, dust, etc., the thermal conductive silicone sheet should be able to resist corresponding corrosion and pollution. For example, for lamps used in chemical enterprises, a thermal conductive silicone sheet with chemical corrosion resistance performance should be selected; for lamps used in industrial workshops with a large amount of dust, the surface of the thermal conductive silicone sheet should not be easy to adsorb dust and can maintain good heat dissipation performance.

(3) Combination with the Lamp Structure and Installation Method

Complexity of the structure: For lamps with a complex structure, limited internal space and irregular components, it is necessary to select a thermal conductive silicone sheet with high softness, good compressibility and easy cutting and processing to adapt to the complex installation space and ensure a tight fit with the heat-generating component and the heat sink. For example, in some uniquely shaped artistic lighting lamps, a thermal conductive silicone sheet with excellent softness, relatively thin thickness (such as 0.8mm) and arbitrary cutting as needed can be selected.

Installation method: If the lamp adopts different installation methods such as screw fastening and buckle connection, the thickness and hardness of the thermal conductive silicone sheet need to be adapted to it. For example, when using the screw fastening method, if the pressure is large, a thermal conductive silicone sheet with slightly higher hardness and moderate thickness can be selected to prevent performance changes caused by excessive compression; when using the buckle connection method, due to the relatively small pressure, a product with better softness can be selected to ensure good thermal contact under a small pressure.

- Application Design of Thermal Conductive Silicone Sheet in High-power Lamps

(1) Application between the LED Chip and the Heat Dissipation Substrate

Installation position and method: In high-power LED lamps, the LED chip is usually welded on the heat dissipation substrate. The thermal conductive silicone sheet should be placed between the LED chip and the heat dissipation substrate to ensure that the heat generated by the chip can be quickly transferred to the heat dissipation substrate. During installation, the thermal conductive silicone sheet needs to be cut into a shape matching the size of the LED chip to accurately cover the surface of the chip and avoid air bubbles or gaps. Generally, manual fitting or fitting with the help of a tooling mold is adopted to ensure the fitting accuracy and tightness.

Thickness and performance selection: According to the gap between the LED chip and the heat dissipation substrate, select a thermal conductive silicone sheet with an appropriate thickness. Generally, when the gap is between 0.5 – 1.5mm, a product with a thickness of 0.6 – 1.8mm can be selected. At the same time, due to the extremely high heat dissipation requirements of the LED chip, a thermal conductive silicone sheet with high thermal conductivity (such as above 4.0W/(m·K)), low thermal resistance, good softness and reliable insulation performance should be selected. For example, for an LED chip with a single power of 50W, a thermal conductive silicone sheet with a thickness of 1.0mm, a thermal conductivity coefficient of 5.0W/(m·K), a Shore hardness of Shore 00 35 and a breakdown voltage of 10kV/mm can be selected.

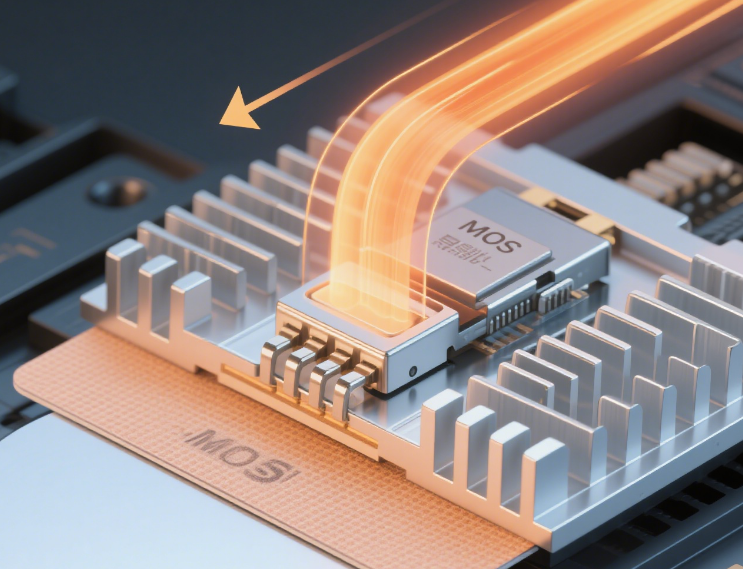

(2) Application between the Driving Power Supply and the Heat Sink

Both electrical isolation and heat dissipation: The driving power supply is an important part of high-power lamps, which will generate a large amount of heat during operation, and there are high voltages inside it. Therefore, when using a thermal conductive silicone sheet between the driving power supply and the heat sink, it is necessary to meet the requirements of both electrical isolation and efficient heat dissipation. The thermal conductive silicone sheet should have good insulation performance (the breakdown voltage is usually required to be above 8kV/mm) to prevent electrical short circuits. During installation, it is necessary to ensure that the thermal conductive silicone sheet completely covers the heat-generating part of the driving power supply and is in close contact with the heat sink.

Consideration of vibration and stability: In some application scenarios of lamps that may be affected by vibration (such as vehicle-mounted lighting lamps), the thermal conductive silicone sheet between the driving power supply and the heat sink also needs to have certain anti-vibration performance and stability. A thermal conductive silicone sheet with high compression modulus and good resilience can be selected to ensure good thermal contact in a vibrating environment and prevent the thermal conductive silicone sheet from shifting or falling off due to vibration. For example, a thermal conductive silicone sheet with a moderate compression modulus, good resilience and a thickness of 2.0mm can be selected, with a thermal conductivity coefficient of 3.5W/(m·K), which can meet the heat dissipation requirements of the driving power supply in a vibrating environment.

(3) Optimization Design in the Overall Heat Dissipation Structure of the Lamp

Cooperation with other heat dissipation components: The thermal conductive silicone sheet does not work independently in the heat dissipation system of high-power lamps, but works in coordination with other heat dissipation components such as the heat sink and the fan (if any). When designing the heat dissipation structure, the cooperation between each component needs to be comprehensively considered. For example, reasonably design the fin structure and spacing of the heat sink to enable the air to form a good convection on the surface of the heat sink, and at the same time, ensure that the thermal conductive silicone sheet can effectively transfer the heat to the heat sink. For lamps using air-cooled heat dissipation, the position and air volume setting of the fan should match the heat dissipation capacity of the thermal conductive silicone sheet and the heat sink to achieve the best heat dissipation effect.

Layout and quantity of the thermal conductive silicone sheet: According to the distribution of the heat-generating components inside the lamp, reasonably layout the position and quantity of the thermal conductive silicone sheet. For areas with concentrated heat generation, the use area or quantity of the thermal conductive silicone sheet can be appropriately increased to improve the heat dissipation efficiency. For example, in a lamp bead module composed of multiple LED chips, a thermal conductive silicone sheet can be placed between each chip and the heat dissipation substrate, and a thermal conductive silicone sheet can be laid in a large area between the lamp bead module and the heat sink to ensure that the heat can be uniformly and quickly transferred to the heat sink. At the same time, care should be taken to avoid excessive use of the thermal conductive silicone sheet, which may lead to increased costs and limited installation space.