Silicone Temperature Resistance: Unveiling the Heat – Enduring Properties

Silicone, a synthetic polymer widely used across various industries, owes its popularity in part to its remarkable temperature resistance. This unique characteristic allows silicone to maintain its physical and chemical properties over a broad temperature range, making it an ideal material for applications where extreme temperatures are a concern.

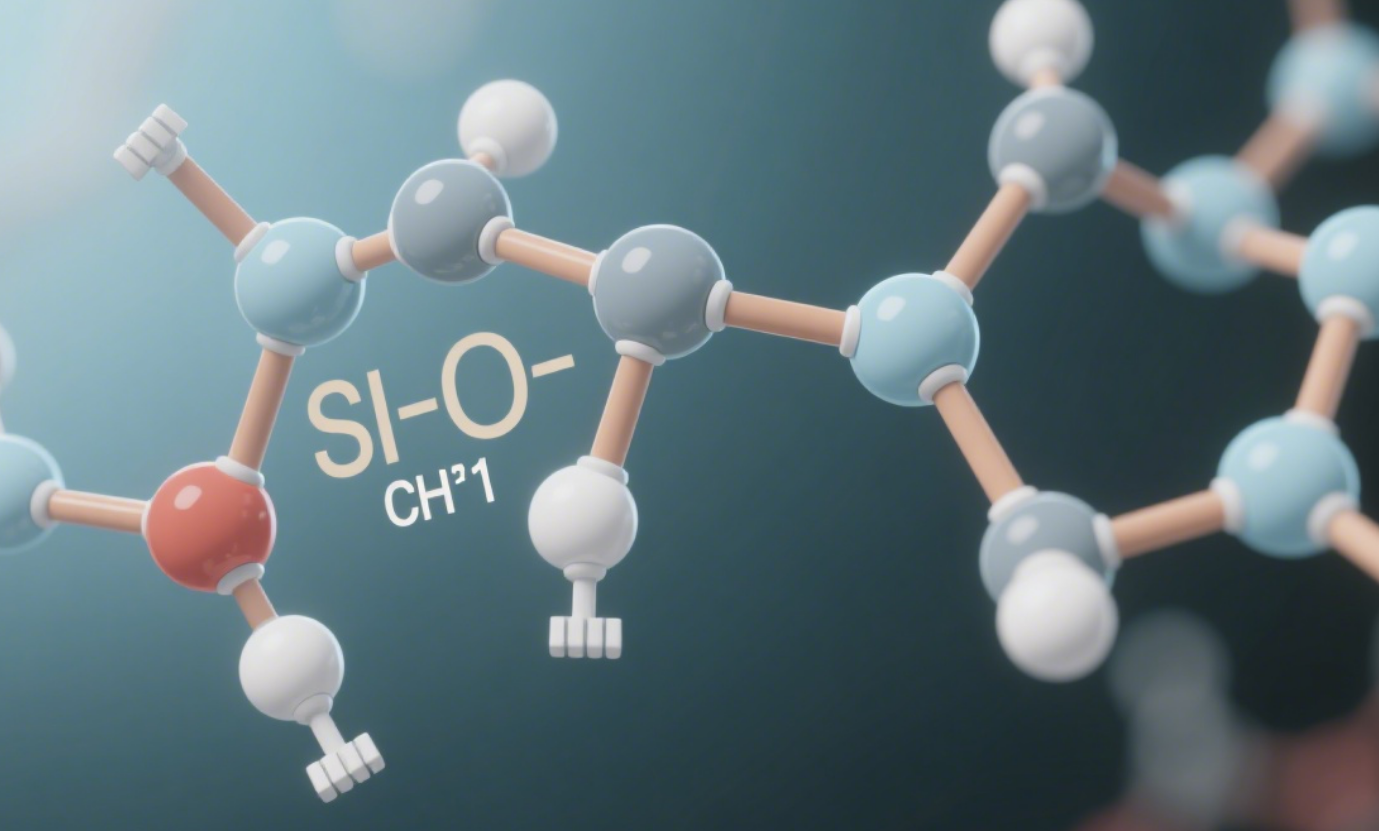

Chemical Structure and the Basis of Temperature Resistance

The molecular structure of silicone is the key to understanding its temperature – resistant capabilities. Silicone polymers are composed of a backbone of alternating silicon and oxygen atoms (Si – O – Si), with organic groups, typically methyl groups (CH₃), attached to the silicon atoms. The Si – O bond has a high bond energy, approximately 460 kJ/mol, which is significantly stronger than many other common chemical bonds. This strong bond energy makes the silicone backbone highly stable and resistant to thermal degradation.

The presence of the organic side groups also contributes to silicone’s temperature – resistant properties. These methyl groups are relatively non – polar and sterically bulky, which reduces intermolecular forces between silicone chains. As a result, silicone polymers have a low glass transition temperature (Tg), often around – 120 °C to – 50 °C, depending on the specific type and formulation. This low Tg allows silicone to remain flexible and rubbery even at extremely low temperatures, preventing brittleness and cracking.

On the high – temperature side, the stability of the Si – O backbone enables silicone to withstand elevated temperatures without significant decomposition. While the exact upper temperature limit can vary depending on the type of silicone and the duration of exposure, many silicones can operate continuously at temperatures ranging from 150 °C to 200 °C, and some high – performance grades can endure short – term exposure up to 300 °C or even higher.

Types of Silicone and Their Temperature Resistance

1. Room Temperature Vulcanizing (RTV) Silicones

RTV silicones are widely used in sealants, adhesives, and coatings. There are two main types: RTV – 1 (one – part) and RTV – 2 (two – part). RTV – 1 silicones cure through a reaction with moisture in the air, while RTV – 2 silicones require a catalyst for curing.

RTV – 1 silicones generally have a good temperature resistance range. They can typically operate continuously at temperatures between – 60 °C and 200 °C. For example, in automotive applications, RTV – 1 silicone sealants are used to seal engine components, where they need to withstand the heat generated during engine operation as well as the cold temperatures during winter starts.

RTV – 2 silicones often offer similar or slightly better temperature resistance. Some high – quality RTV – 2 formulations can endure continuous operation at up to 250 °C and short – term exposure to even higher temperatures. They are commonly used in more demanding applications, such as in the aerospace industry for sealing and bonding components that are exposed to a wide range of temperatures during flight.

2. High – Temperature Vulcanizing (HTV) Silicones

HTV silicones are processed by molding or extrusion and require high – temperature curing. These silicones are known for their excellent mechanical properties and enhanced temperature resistance compared to RTV silicones.

HTV silicones can typically operate continuously at temperatures between – 55 °C and 200 °C. However, special high – performance HTV silicones have been developed that can withstand continuous operation at temperatures up to 300 °C. These high – temperature – resistant HTV silicones are used in applications such as high – temperature gaskets, oven seals, and electrical insulation in high – temperature environments. For instance, in industrial furnaces, HTV silicone gaskets maintain their sealing integrity while being exposed to the intense heat inside the furnace.

3. Fluorosilicone

Fluorosilicone is a specialized type of silicone where some of the methyl groups in the silicone structure are replaced by fluorine – containing groups. This modification significantly improves the chemical resistance and also enhances the temperature resistance of the silicone.

Fluorosilicone can operate continuously at temperatures ranging from – 60 °C to 200 °C, with some formulations capable of withstanding short – term exposure up to 250 °C. Its unique combination of temperature resistance and excellent resistance to chemicals, oils, and fuels makes it highly valuable in applications such as automotive fuel systems, where it needs to resist both the heat from the engine and the corrosive effects of fuel.

Applications Demonstrating Silicone’s Temperature Resistance

1. Electrical and Electronics

In the electrical and electronics industry, silicone is widely used for insulation. For example, silicone rubber is used to coat electrical wires and cables. In high – temperature environments, such as in power plants or electronic devices with high – heat – generating components, silicone insulation maintains its electrical insulating properties and physical integrity. It prevents electrical shorts and protects the wires from degradation due to heat, ensuring the safe and reliable operation of electrical systems.

Silicone – based potting compounds are also used to encapsulate electronic components. These compounds fill the spaces around components, providing protection against moisture, dust, and mechanical shock, while also dissipating heat effectively. The temperature resistance of silicone allows the encapsulated components to operate within their optimal temperature range, even in high – temperature environments.

2. Automotive

The automotive industry heavily relies on silicone’s temperature – resistant properties. Silicone gaskets are used throughout the engine to seal joints and prevent leaks of coolant, oil, and fuel. These gaskets need to withstand the high temperatures generated during engine operation, which can reach up to 200 °C or more in some areas of the engine. Additionally, silicone hoses are used for coolant and air intake systems. They maintain their flexibility and integrity in both extreme cold winter conditions and the intense heat of the engine compartment, ensuring the proper flow of fluids and air for the engine’s efficient operation.

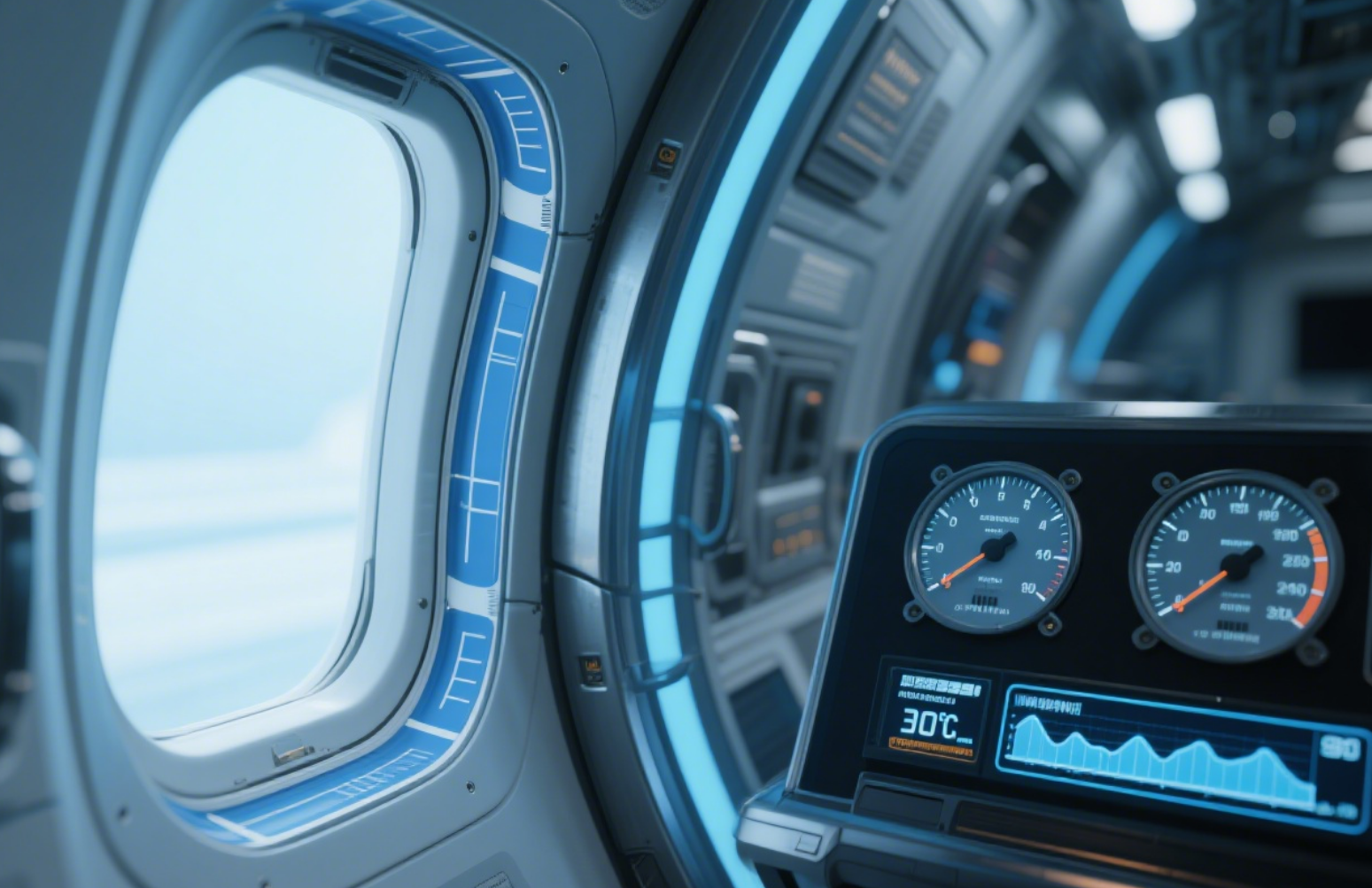

3. Aerospace

In the aerospace field, where components are exposed to a wide range of temperatures during flight, silicone is indispensable. Silicone sealants are used to seal aircraft windows, doors, and other structural joints, preventing air leakage and maintaining cabin pressure. These sealants can endure the extreme cold of high – altitude flight (temperatures can drop to – 50 °C or lower) as well as the heat generated during takeoff, landing, and engine operation (which can reach several hundred degrees Celsius in some areas). Silicone – based materials are also used for insulation in aircraft electrical systems and for gaskets in engine components, ensuring the safety and reliability of the aircraft in all temperature conditions.

Challenges and Future Prospects

Although silicone exhibits excellent temperature resistance, there are still challenges in certain extreme conditions. At very high temperatures, especially when exposed to oxygen for extended periods, silicone can gradually oxidize, leading to a degradation of its mechanical and physical properties. To address this, researchers are exploring the development of new silicone formulations with improved oxidation resistance, such as adding special additives or modifying the silicone structure.

In the future, as industries continue to demand materials that can perform reliably in even more extreme temperature environments, the research and development of silicone will likely focus on further enhancing its temperature – resistant capabilities. This may involve the use of nanotechnology to create silicone – based nanocomposites with superior thermal stability, as well as the development of new manufacturing processes to produce high – performance silicone materials more efficiently.

In conclusion, silicone’s temperature resistance is a defining characteristic that has enabled its widespread use in numerous industries. Its unique chemical structure, combined with the development of different types of silicone formulations, has made it a versatile material capable of withstanding a wide range of temperatures. As technology advances, silicone is expected to play an even more crucial role in applications where temperature resistance is of utmost importance.