Protection of Electronic Products by Microwave Shielding Materials

2025/09/09

0

With the rapid development of electronic technology today, various electronic products have penetrated into every aspect of people’s lives and work. However, the interference and hazards caused by microwave radiation constantly threaten the normal operation and service life of electronic products. Against this background, microwave shielding materials have emerged as an important barrier to protect electronic products.

- Definition of Microwave Shielding Materials and the Necessity of Protection

Microwave shielding materials are a type of functional materials that can effectively prevent the penetration of microwave radiation. Their core mechanism of action is to cut off the propagation path of microwaves by reflecting, absorbing, or attenuating microwave energy, thereby reducing the impact of microwaves on the protected objects.

The harm of microwave radiation to electronic products cannot be ignored. On the one hand, external microwave radiation may interfere with the internal electromagnetic environment of electronic products, affect the stability of signal transmission, and lead to problems such as data errors and communication interruptions. For example, during mobile phone communication, if subjected to strong microwave interference, there may be call noise, dropped calls, and other situations. On the other hand, long-term exposure to microwave radiation will damage the internal components of electronic products due to the accumulation of electromagnetic energy, shortening their service life. Precision components such as chips and sensors are particularly sensitive to microwave radiation and are easily disabled by interference. Therefore, equipping electronic products with appropriate microwave shielding materials is a necessary measure to ensure their normal operation and extend their service life.

- Types and Characteristics of Microwave Shielding Materials

At present, common microwave shielding materials mainly include metal materials, conductive polymer materials, and composite materials.

Metal materials are traditional and widely used microwave shielding materials, such as copper, aluminum, and iron. They have excellent shielding performance, with a shielding effectiveness usually reaching 60-100dB. This is because metals have good conductivity and can strongly reflect microwaves, thereby preventing their penetration. However, metal materials also have obvious defects, such as heavy weight and poor flexibility, making them unsuitable for electronic products with strict requirements on weight and shape, such as portable smart devices.

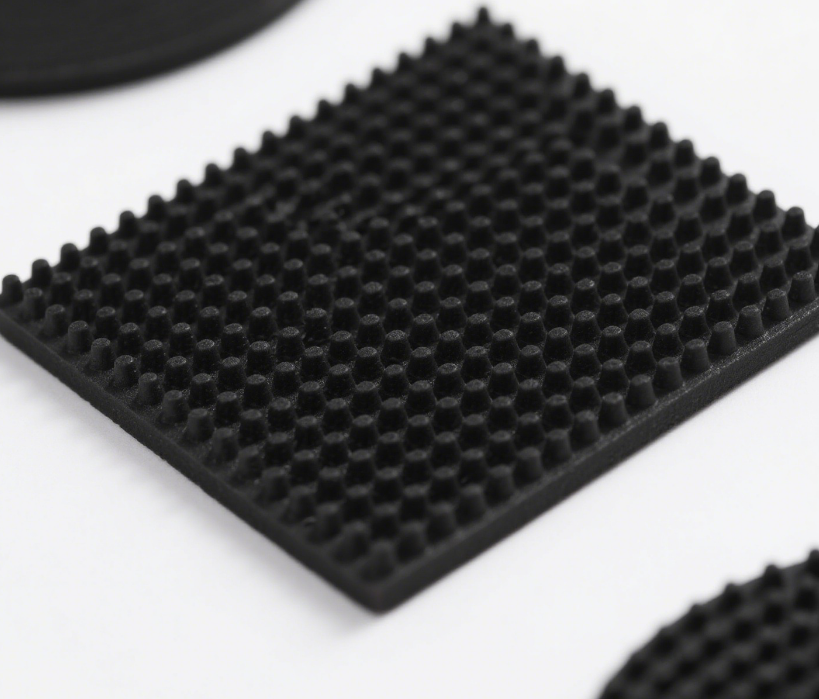

Conductive polymer materials are shielding materials formed by endowing polymer materials with conductivity through doping, compounding, and other methods. Common ones include conductive plastics and conductive rubbers. These materials are lightweight, flexible, and have excellent processing properties, can be made into various complex shapes, and are very suitable for portable electronic products. Their shielding effectiveness is generally 30-60dB, which, although not as good as that of metal materials, can meet the shielding needs of most daily electronic products.

Composite materials are microwave shielding materials made by combining the advantages of multiple materials. For example, compounding metal powders, carbon fibers, etc., with polymer materials can obtain composite materials with high shielding effectiveness, lightweight, and good mechanical properties. Their shielding effectiveness can be adjusted according to the formula, usually between 40-80dB, and they have a wide range of applications, being suitable for both large electronic equipment and small precision electronic products.

- Specific Applications of Microwave Shielding Materials in Electronic Products

Microwave shielding materials have important applications in various electronic products.

In portable electronic products such as mobile phones and laptops, conductive polymer materials and composite materials are widely used. Components such as the 外壳 (shells) and internal shielding covers of mobile phones often use these materials to prevent external microwave interference with the normal operation of internal circuits, and also to avoid excessive radiation from microwaves generated by the mobile phones themselves to the human body. Key parts of laptops, such as displays and motherboards, also use microwave shielding materials to ensure the accuracy of data processing and transmission.

In large electronic equipment such as radar equipment and communication base stations, metal materials and high-performance composite materials are more common. Radar equipment generates strong microwave signals during operation. To avoid interference with other surrounding electronic equipment and prevent external microwaves from affecting its detection accuracy, metal shielding covers or composite material shields are usually used. Communication base stations need to resist various microwave interferences in complex electromagnetic environments to ensure stable signal transmission, and high-performance microwave shielding materials are an important guarantee for their reliable operation.

In medical electronic equipment, such as nuclear magnetic resonance instruments and electrocardiographs, the requirements for the electromagnetic environment are extremely high. The application of microwave shielding materials can effectively isolate external microwave interference, ensure the accuracy of medical equipment detection data, and provide a reliable basis for disease diagnosis.

- Development Trends of Microwave Shielding Materials

As electronic products develop towards miniaturization, lightweight, and high performance, higher requirements are put forward for microwave shielding materials.

In the future, microwave shielding materials will develop towards being thinner and lighter. On the premise of ensuring shielding effectiveness, the thickness and weight of materials will be reduced to meet the needs of miniaturization of electronic products. At the same time, higher shielding effectiveness is a continuous pursuit, especially in some fields with extremely harsh requirements on the electromagnetic environment, such as aerospace electronic equipment, which requires materials with higher shielding effectiveness to cope with complex microwave interference.

In addition, reducing costs is also an important trend in the development of microwave shielding materials. By developing new preparation processes and finding cheap alternative raw materials, the production cost of materials can be reduced, enabling them to be more widely used in various electronic products.

用英文介绍一下微波屏蔽材料的应用领域

请再提供一些不同风格的关于微波屏蔽材料的英文文本。

把这段中文文本的句式结构调整一下,再翻译成英文。