Oil-Resistant Silicone Rubber: A High-Performance Material Empowering Multiple Fields

2025/10/16

0

In the fields of industrial production and modern manufacturing, the performance of materials often directly determines the stability, safety, and service life of equipment. As a polymer material with special properties, oil-resistant silicone rubber, relying on its outstanding dual core characteristics of “oil resistance” and “temperature resistance”, occupies an irreplaceable position in several key industries and has become an important basic material for ensuring the efficient operation of equipment.

I. Core Characteristics: Defining the Application Boundaries of the Material

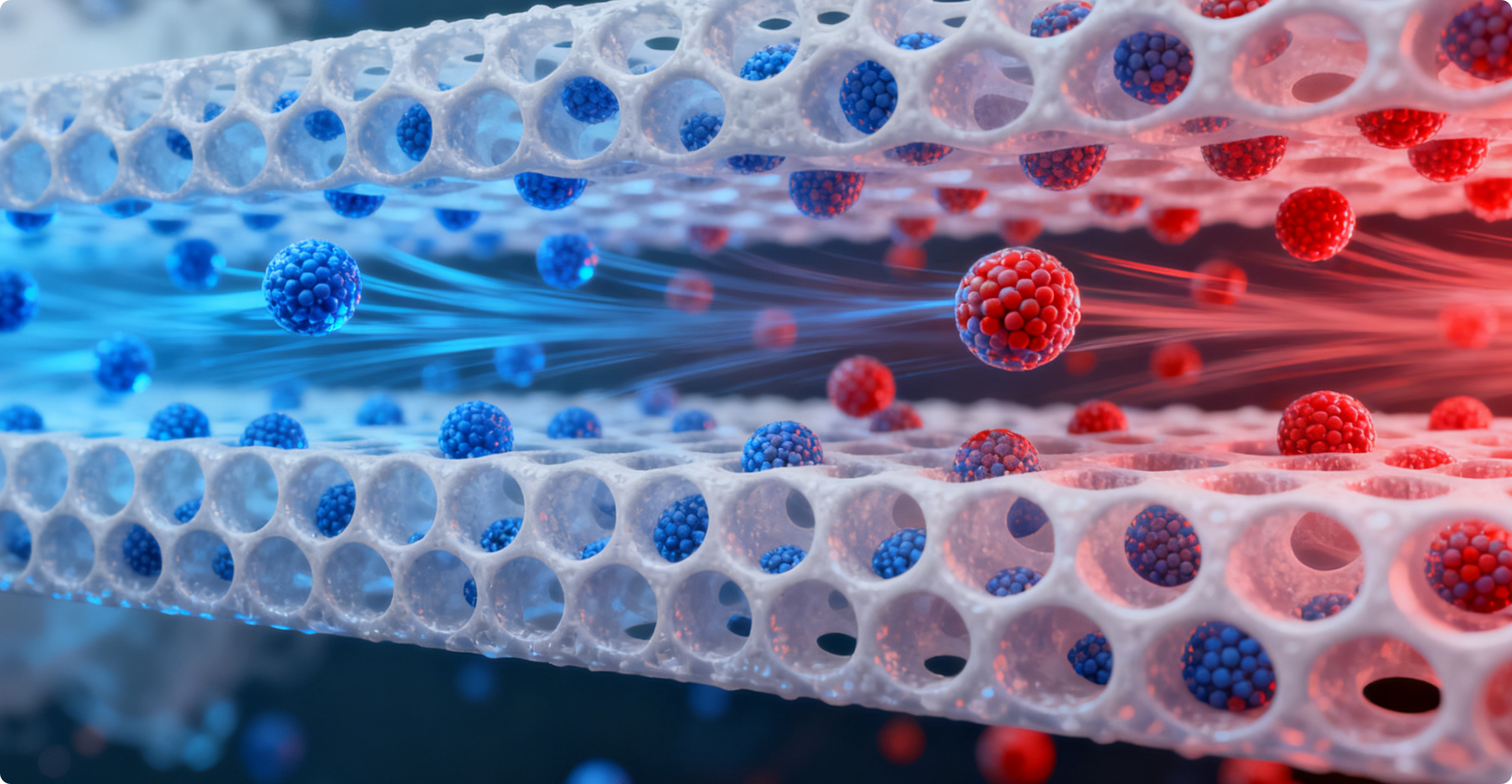

The value of oil-resistant silicone rubber first stems from the perfect combination of its two core characteristics. In terms of oil resistance, it can effectively resist the erosion of various oil media such as engine oil, fuel oil, lubricating oil, and hydraulic oil, preventing the material from losing its sealing performance due to swelling, deformation, or aging. This characteristic makes it an ideal choice for environments in contact with oil. In terms of temperature resistance, it can maintain stable performance within a wide temperature range. Whether in the high-temperature environment when an automobile engine is running or the low-temperature conditions in some industrial scenarios, it can function normally, effectively solving the problem of performance failure of traditional rubber under extreme temperatures.

II. Three Core Application Fields: From Industry to Special Scenarios

(1) Automotive Industry: The Core Material for Ensuring the Stability of Power Systems

The automotive industry is the core application field of oil-resistant silicone rubber, which plays a crucial sealing role in the engine system, fuel system, and transmission system of automobiles. In the engine system, the engine generates high temperatures during operation and is filled with engine oil inside. Oil seals, O-rings, and gaskets made of oil-resistant silicone rubber can achieve tight sealing in high-temperature environments, preventing engine oil leakage, ensuring sufficient lubrication inside the engine, reducing wear of components, and guaranteeing the efficient operation of the engine. In the fuel system, fuel pipes and fuel pump seals are in direct contact with fuel. With excellent fuel permeability resistance and corrosion resistance, oil-resistant silicone rubber can effectively prevent fuel permeation, avoid safety hazards caused by fuel leakage, and at the same time prevent fuel from corroding the seals, thereby extending the service life of the fuel system. In the transmission system, the gear oil in the gearbox will erode the seals. The gearbox seals made of oil-resistant silicone rubber can resist the erosion of gear oil, maintain a good sealing effect, ensure the smooth power transmission of the gearbox, and improve the reliability of the automobile transmission system.

(2) Industrial Equipment and Machinery: A Reliable Choice for Key Sealing Components

Oil-resistant silicone rubber is also indispensable in various industrial equipment and machinery that require lubrication and leak prevention, providing guarantee for the stable operation of the equipment. In hydraulic and pneumatic systems, sealing rings and diaphragms are key components, and the hydraulic oil and compressed oil in the system will have an impact on them. These components made of oil-resistant silicone rubber can withstand the effects of hydraulic oil and compressed oil, maintain good elasticity and sealing performance, prevent leakage of hydraulic oil or compressed oil, ensure stable pressure of hydraulic and pneumatic systems, and realize precise control of the equipment. In the field of general machinery, equipment such as vacuum pumps and compressors will not only come into contact with oil pollution during operation but also face losses caused by friction. Seals made of oil-resistant silicone rubber can not only cope with oil-polluted environments but also maintain sealing performance under friction conditions, reducing the leakage of gas or liquid inside the equipment and improving the working efficiency and service life of general machinery. In addition, in food machinery, some oil-resistant silicone rubber that meets food-grade standards can be used for seals in contact with edible oil. It not only has excellent oil resistance but also can meet food hygiene requirements, avoid pollution to food, and ensure the safety of food production.

(3) Petrochemical and Special Fields: A Performance Leader in Extreme Environments

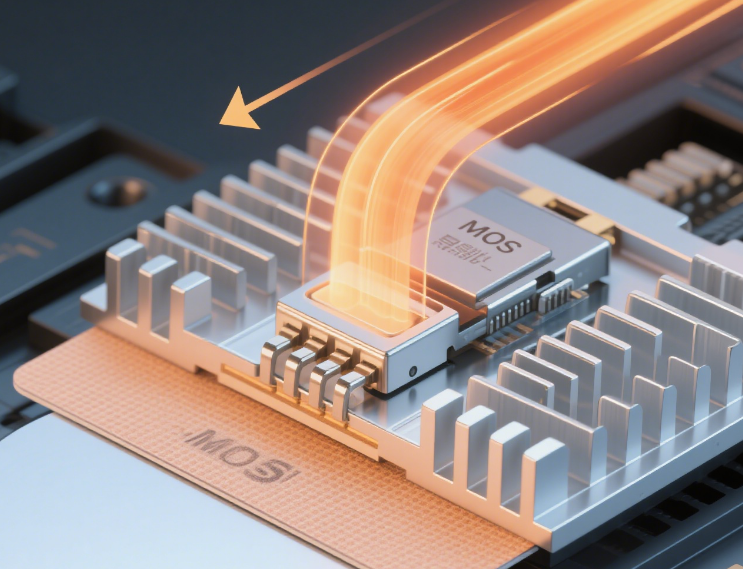

In the petrochemical and special fields with heavier oil pollution and more complex environments, the chemical resistance and stability of oil-resistant silicone rubber are fully exerted. During oil exploitation, downhole tools need to work in complex environments filled with crude oil and drilling fluid. The downhole tool seals made of oil-resistant silicone rubber can withstand the erosion of crude oil and drilling fluid, prevent leakage of downhole fluids, and ensure the safe and efficient progress of oil exploitation operations. In the application of special pipelines, the sealing of pipeline joints for transporting oil media is crucial. Oil-resistant silicone rubber can be used as a seal for pipeline joints to ensure no leakage of oil media during transportation; at the same time, it can also be used as a pipeline lining to reduce the adhesion of oil pollution on the inner wall of the pipeline, lower the difficulty of pipeline cleaning, and extend the service life of the pipeline. In the field of electronic equipment, some industrial electronic equipment may be in an environment with oil pollution. The waterproof and oil-resistant cable joints or connector seals made of oil-resistant silicone rubber can effectively block oil pollution and moisture from entering the interior of electronic equipment, protect electronic components from damage, and ensure the stable operation of industrial electronic equipment.

III. Market Prospects: Sustained Development Driven by Demand

As the automotive industry moves towards new energy and intelligence, the performance requirements for automotive components continue to increase, and the application demand for oil-resistant silicone rubber in new fields such as the battery cooling system and motor system of new energy vehicles is gradually growing. At the same time, the improvement of industrial automation level has promoted the growth of demand for high-performance seals in industrial equipment, and the continuous development of the petrochemical industry has also provided a broader application space for oil-resistant silicone rubber. In the future, with the continuous innovation of material technology, the performance of oil-resistant silicone rubber in terms of oil resistance, temperature resistance, and chemical resistance will be further improved, its application fields will be continuously expanded, and the market scale is expected to expand sustainably, making it an important material support for promoting the high-quality development of related industries.