Electronic shielding rubber in mobile base stations

2025/06/13

0

Function

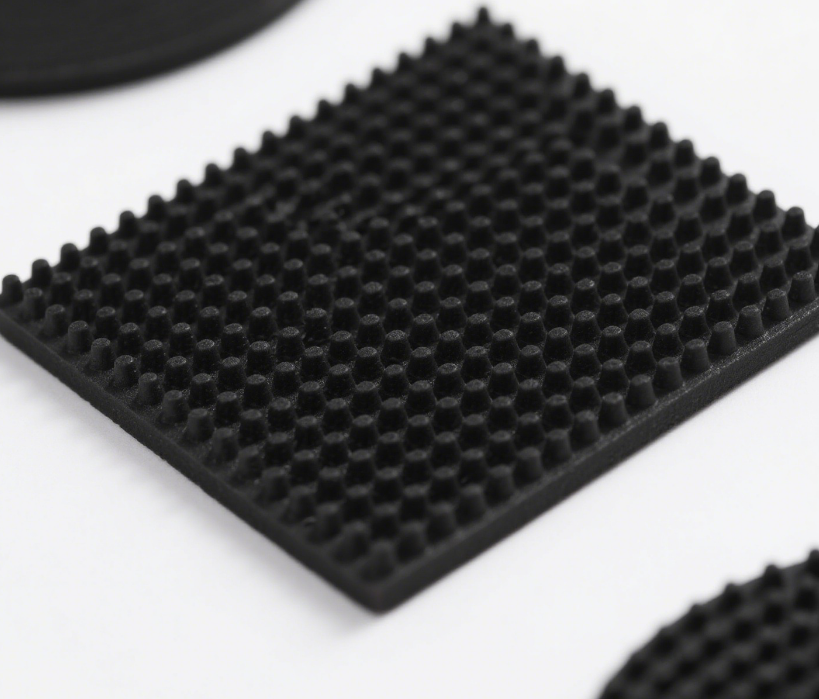

Electromagnetic Shielding: When mobile base stations are in operation, they generate electromagnetic radiation. Electronic shielding rubber, through its own electrical conductivity, utilizes the eddy current effect and reflection effect of conductors to confine electromagnetic waves within the base station. This reduces electromagnetic radiation leakage and prevents interference with internal components, signal units, surrounding equipment, and the environment.

Sealing and Vibration Damping: It can fill gaps between the base station housing and components, providing a sealing function to prevent dust, moisture, etc., from entering the interior. Meanwhile, it can absorb vibrations to a certain extent, reducing potential component damage or poor contact caused by vibration.

Thermal Conductivity: Some electronic shielding rubbers also have thermal conductivity, which can conduct heat generated by internal electronic components of the base station, avoiding heat accumulation that may affect the service life and normal operation of electronic components.

Sealing and Vibration Damping: It can fill gaps between the base station housing and components, providing a sealing function to prevent dust, moisture, etc., from entering the interior. Meanwhile, it can absorb vibrations to a certain extent, reducing potential component damage or poor contact caused by vibration.

Thermal Conductivity: Some electronic shielding rubbers also have thermal conductivity, which can conduct heat generated by internal electronic components of the base station, avoiding heat accumulation that may affect the service life and normal operation of electronic components.

Working Principle

Chain-type Conductive Pathway: In composite conductive silicone rubber elastomers, when filler particles approach each other within a distance of a few tenths of a nanometer, a pressure difference is generated, causing the π electrons of the filler particles to move through chain-type transmission, thus enabling current to pass and forming a conductive pathway. When the filler dosage reaches a certain level, obvious conductive phenomena occur, achieving electromagnetic shielding.

Tunnel Effect: When conductive particles do not contact each other, there is a polymer isolation layer between them, hindering the directional movement of free electrons in the conductive particles and forming a potential barrier with a certain potential energy. When the energy of microscopic particles is lower than the potential barrier energy, they may either bounce back or pass through the barrier. This phenomenon is called the tunnel effect, which also endows rubber with certain conductive and shielding properties.

Tunnel Effect: When conductive particles do not contact each other, there is a polymer isolation layer between them, hindering the directional movement of free electrons in the conductive particles and forming a potential barrier with a certain potential energy. When the energy of microscopic particles is lower than the potential barrier energy, they may either bounce back or pass through the barrier. This phenomenon is called the tunnel effect, which also endows rubber with certain conductive and shielding properties.

Performance Requirements

Electrical Conductivity: To achieve good electromagnetic shielding effects, electronic shielding rubber needs high electrical conductivity, typically improved by adding conductive fillers such as carbon black, nano-metal powders, and metal fibers.

Mechanical Properties: Base station integrators have strict requirements for tensile strength, tear strength, elongation at break, and compression set to ensure that the rubber can withstand certain external forces during installation and use, is not easily damaged, and maintains good sealing and shielding performance in long-term use.

Environmental Resistance: Due to the harsh working environment of outdoor base stations, electronic shielding rubber must withstand long-term high temperatures, severe cold, humidity, and corrosive environments, with good aging resistance and weatherability to ensure stable performance.

Thermal Conductivity: For base stations with heat dissipation requirements, electronic shielding rubber also needs a certain thermal conductivity to effectively conduct heat. Thermal conductive materials such as aluminum oxide and flake graphite are usually added to improve thermal conductivity.

Flame Retardancy: To prevent fire hazards, electronic shielding rubber should have good flame retardancy to avoid fueling fire spread in case of a base station fire.

Mechanical Properties: Base station integrators have strict requirements for tensile strength, tear strength, elongation at break, and compression set to ensure that the rubber can withstand certain external forces during installation and use, is not easily damaged, and maintains good sealing and shielding performance in long-term use.

Environmental Resistance: Due to the harsh working environment of outdoor base stations, electronic shielding rubber must withstand long-term high temperatures, severe cold, humidity, and corrosive environments, with good aging resistance and weatherability to ensure stable performance.

Thermal Conductivity: For base stations with heat dissipation requirements, electronic shielding rubber also needs a certain thermal conductivity to effectively conduct heat. Thermal conductive materials such as aluminum oxide and flake graphite are usually added to improve thermal conductivity.

Flame Retardancy: To prevent fire hazards, electronic shielding rubber should have good flame retardancy to avoid fueling fire spread in case of a base station fire.

Application Methods

Overall Shielding of Base Station Housing: Install conductive rubber strips at the die-casting joints of the base station housing, making the aluminum alloy housing form a continuous conductor to confine electromagnetic waves within the base station.

Local Shielding of Internal Electronic Components: For internal electronic components of the base station, the in-situ forming (FIP) process can be used. Conductive adhesives are precisely coated on the parts requiring shielding, and after curing, they form a conductive and elastic “wall” to achieve local shielding.

Local Shielding of Internal Electronic Components: For internal electronic components of the base station, the in-situ forming (FIP) process can be used. Conductive adhesives are precisely coated on the parts requiring shielding, and after curing, they form a conductive and elastic “wall” to achieve local shielding.