electronic shielding rubber in Medical Equipment

2025/06/16

0

Overview

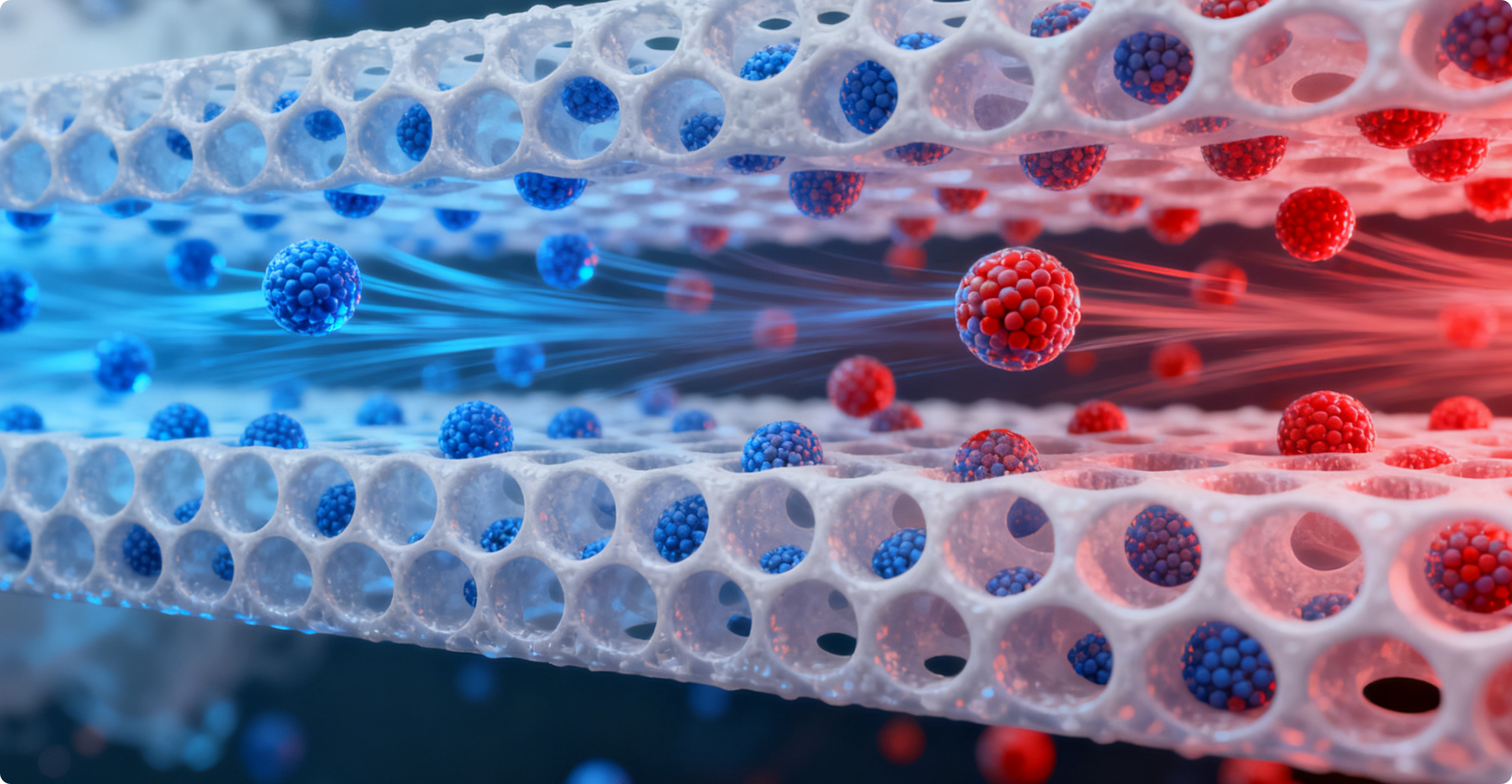

Electromagnetic shielding rubber typically refers to a composite material made by uniformly distributing conductive particles such as silver-plated glass, silver-plated aluminum, silver, and nickel-plated graphite in a matrix like silicone rubber. Through pressure, the conductive particles make contact, achieving excellent electrical conductivity and electromagnetic shielding performance.

Electromagnetic shielding rubber typically refers to a composite material made by uniformly distributing conductive particles such as silver-plated glass, silver-plated aluminum, silver, and nickel-plated graphite in a matrix like silicone rubber. Through pressure, the conductive particles make contact, achieving excellent electrical conductivity and electromagnetic shielding performance.

Functions

- Prevention of Electromagnetic Interference (EMI): Medical devices often operate in environments with multiple electronic devices. Electromagnetic shielding rubber can block external electromagnetic waves from entering the device, preventing interference with its normal operation. It also prevents electromagnetic waves generated by the device from radiating outward, avoiding impacts on surrounding equipment.

- Ensuring Stable Device Performance: It avoids issues such as signal noise and data transmission errors, ensuring that medical devices like magnetic resonance imaging (MRI), computed tomography (CT), electrocardiographs, and ventilators accurately collect, process, and display data. This reduces device failures or measurement errors caused by EMI, safeguarding the stability and reliability of device performance.

- Enhancing Medical Safety: For critical medical devices such as life support systems and pacemakers, electromagnetic shielding rubber effectively prevents EMI from affecting the devices, avoiding malfunctions or errors, and thus protecting patients’ lives.

Principle

When an external electromagnetic field reaches the surface of the conductive rubber, intense electromagnetic waves act on the free electrons of the conductive particles. The free electrons move freely, generating an electromagnetic field opposite to the external one during their motion. The internal and external electromagnetic fields cancel each other out, weakening the interfering electromagnetic waves and achieving electromagnetic shielding.

When an external electromagnetic field reaches the surface of the conductive rubber, intense electromagnetic waves act on the free electrons of the conductive particles. The free electrons move freely, generating an electromagnetic field opposite to the external one during their motion. The internal and external electromagnetic fields cancel each other out, weakening the interfering electromagnetic waves and achieving electromagnetic shielding.

Features

- Excellent Electromagnetic Shielding Effectiveness: It provides high-efficiency electromagnetic shielding within a specific frequency range, effectively attenuating EMI signals. The shielding effectiveness can reach 90 dB–120 dB or even higher.

- Superior Sealing Performance: In addition to electromagnetic shielding, it has excellent sealing properties, preventing water vapor, dust, liquids, etc., from entering the interior of medical devices. This protects internal circuits and components from environmental factors.

- Good Flexibility and Mechanical Properties: The rubber matrix endows the material with excellent flexibility and elasticity, enabling it to adapt to the shape and size requirements of different parts of medical devices. It can closely fit various complex structures and surfaces, withstand a certain degree of deformation and vibration, and is not prone to cracking or damage.

- Chemical Stability and Corrosion Resistance: It shows good tolerance to common chemicals, disinfectants, cleaning agents, etc., in medical environments, and is less likely to undergo chemical reactions that cause performance degradation or damage. This ensures stable shielding and sealing performance during long-term use.

- Strong Designability: According to the needs of different medical devices, shielding rubber products with specific properties and shapes (such as molded gaskets, extruded rubber strips, coated conductive rubber strips, etc.) can be customized by adjusting the formula, selecting different conductive fillers and matrix materials, and changing processing techniques.

Application Examples

- Medical Imaging Equipment: In devices like MRI and CT, electromagnetic shielding rubber is used in parts such as casings, observation windows, and cable interfaces to prevent external electromagnetic waves from interfering with imaging signals, ensuring image clarity and accuracy. It also prevents the strong magnetic fields generated by the devices from affecting surrounding equipment and personnel.

- Life Support Equipment: In life support devices such as ventilators, anesthetic machines, and pacemakers, electromagnetic shielding rubber ensures stable operation in complex electromagnetic environments, preventing EMI-induced failures or malfunctions and protecting patients’ lives.

- Medical Monitoring Equipment: Monitoring devices like electrocardiographs and electroencephalographs use electromagnetic shielding rubber to effectively suppress external EMI, improve the signal-to-noise ratio, and ensure the accuracy and reliability of monitoring data, providing an accurate basis for medical diagnosis.

- Laboratory Analysis Equipment: For equipment such as blood analyzers and DNA analyzers, electromagnetic shielding rubber helps reduce the impact of external EMI on internal precision circuits and sensors, ensuring the accuracy of analysis results.