Application of Multifunctional PDMS Membranes

2025/12/23

0

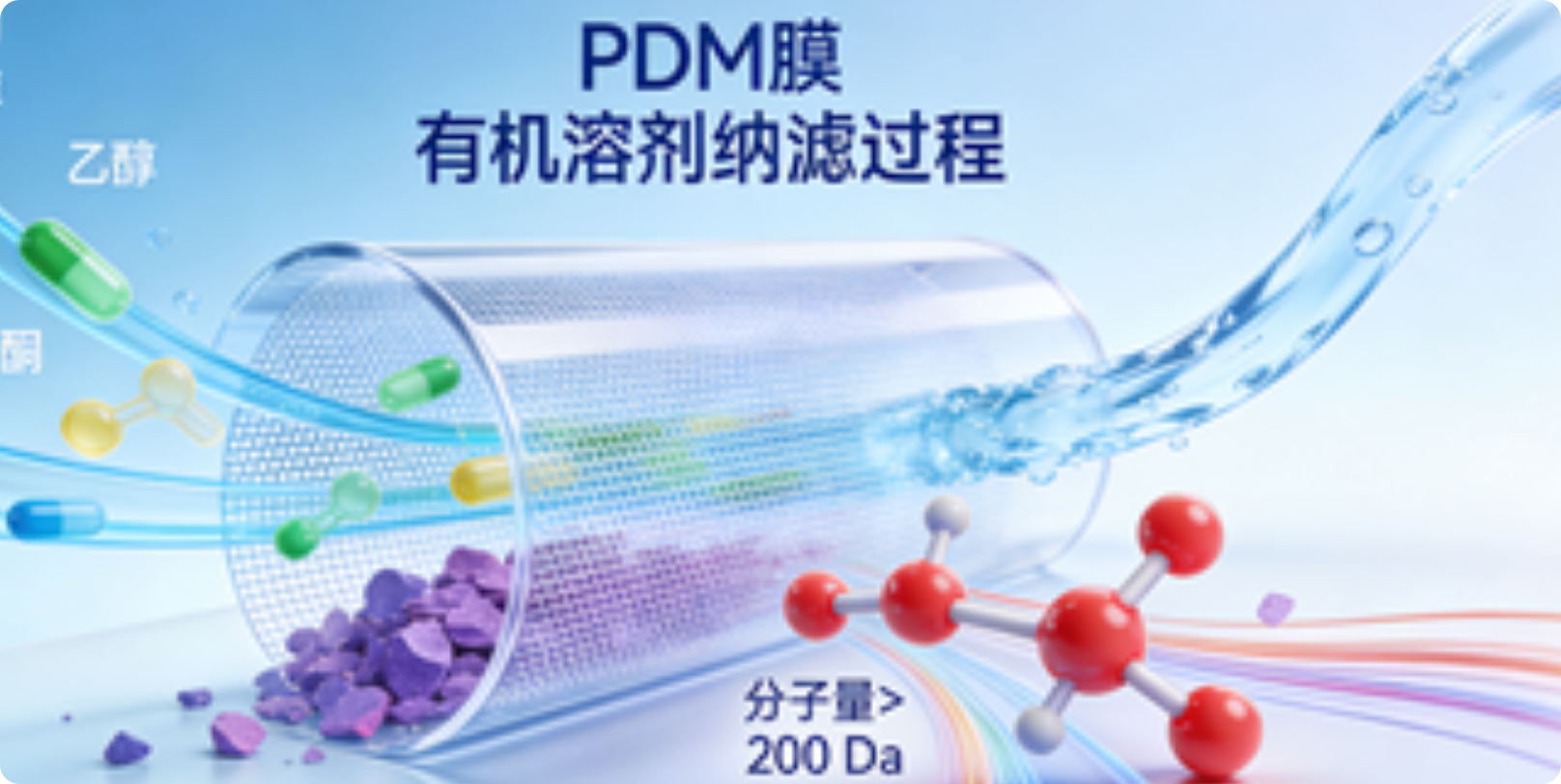

I. Liquid Separation Field: Core Advantages and Scenario Implementation (Continued)

The previous section has elaborated on the core applications of PDMS membranes in organic solvent nanofiltration (OSN), oil-water separation, and pervaporation (PV) separation. Their common advantages can be summarized as “three highs and two lows”: high solvent resistance, high selectivity, high stability, low energy consumption, and low pollution sensitivity. In practical engineering applications, the modular design of PDMS membranes enables flexible adaptation to different treatment scales — from lab-scale precision separation (e.g., purification of antibiotics at the milligram level) to industrial-scale large-volume wastewater treatment (with a daily processing capacity exceeding 1,000 tons), all demonstrating stable separation performance.

Application of Multifunctional PDMS Membranes

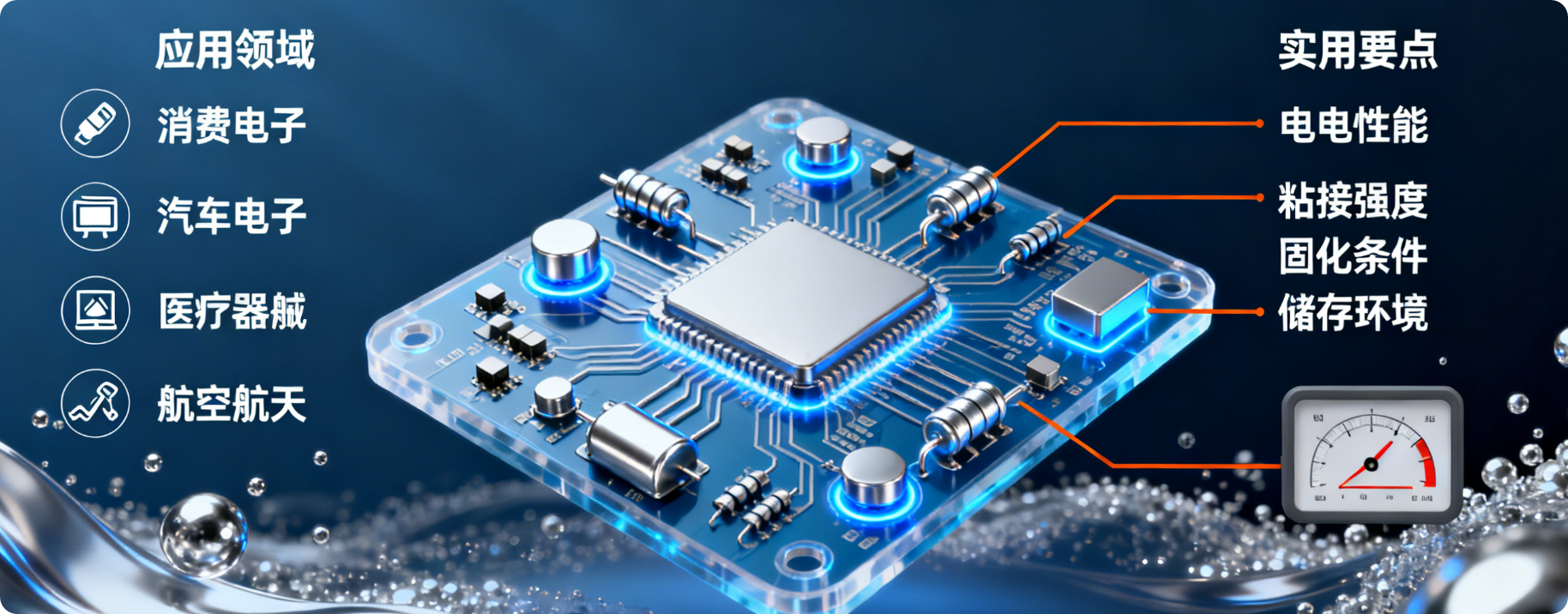

II. Energy and Electronics Field: Innovative Applications of Functional Membrane Materials

With the development of new energy technologies, the applications of high-performance PDMS membranes in fuel cells, flexible electronics, and other fields are continuously expanding, with their high gas permeability, flexibility, and stability serving as core advantages.

1. Proton Exchange Membranes for Fuel Cells

Modified PDMS membranes (e.g., doped with sulfonic acid groups or composite inorganic nanoparticles) can significantly enhance proton conduction efficiency (with proton conductivity reaching 0.01–0.1 S/cm) while maintaining excellent chemical stability (performance attenuation < 5% after continuous operation for 1,000 hours at 80℃ and 100% relative humidity). Compared with traditional perfluorosulfonic acid membranes, PDMS-based composite membranes reduce costs by 30–40% and exhibit superior methanol crossover resistance (methanol permeability < 1×10⁻⁶ cm²/s), making them suitable for scenarios such as direct methanol fuel cells (DMFC) and proton exchange membrane fuel cells (PEMFC). Currently, such membrane materials have been put into pilot-scale applications in portable power supplies, auxiliary power supplies for new energy vehicles, and other fields.

2. Flexible Electronic Packaging and Breathable Membranes

The high flexibility (elongation at break > 300%), low modulus (< 1 MPa), and excellent gas permeability (oxygen permeability reaching 1×10⁴–1×10⁵ Barrer) of PDMS membranes make them ideal packaging materials for flexible electronic devices. Through surface modification (e.g., plasma treatment, coating modification), selective barrier properties against water vapor can be achieved (water vapor transmission rate < 1 g/(m²·day)), while allowing the heat and gas generated during device operation to dissipate. This extends the service life of devices such as flexible displays and wearable sensors (no significant aging after 500 cycles of use in environments ranging from -40℃ to 85℃). In addition, PDMS breathable membranes can also be applied to the modification of separators for lithium-sulfur batteries, inhibiting the polysulfide shuttle effect and improving battery cycle stability (capacity retention rate > 80% after 500 cycles).

3. Hydrogen Separation and Purification Membranes

PDMS membranes boast excellent hydrogen selectivity (H₂/CO₂ separation factor reaching 10–20), along with outstanding high-pressure and low-temperature resistance (capable of stable operation at -50℃ to 150℃ and pressure ≤ 10 MPa). They are suitable for gas separation in hydrogen production (e.g., purification of H₂ from methane reforming gas, recovery of H₂ from industrial off-gas). Separation systems adopting PDMS-based composite membranes can increase hydrogen purity from 70–80% to over 99.9%, with energy consumption reduced by 20–30% compared with traditional pressure swing adsorption (PSA) technology. These membranes have been applied in demonstration projects such as off-gas recovery in chemical enterprises and hydrogen supply systems for hydrogen fuel cells.

III. Directions for Material Modification and Performance Optimization

To further expand the application boundaries of PDMS membranes, current research focuses on the following three major modification pathways:

- Composite Modification: By compounding with nanomaterials such as MOFs, GO, and CNTs, the mechanical strength of the membrane is enhanced (tensile strength increased from 0.5 MPa to 2–5 MPa) and separation selectivity is improved (e.g., the molecular cut-off precision of OSN membranes can be raised to below 100 Da).

- Surface Functionalization: Technologies such as graft polymerization and ionic liquid doping are used to regulate the hydrophilic-hydrophobic properties of the membrane surface (water contact angle can be adjusted within the range of 30°–150°), adapting to the requirements of different separation systems.

- Structure Regulation: Porous PDMS membranes are prepared using methods such as electrospinning and phase inversion to improve flux (e.g., the flux of oil-water separation membranes can reach 1,000–5,000 L/(m²·h·bar)) while maintaining high separation efficiency.

IV. Market Prospects and Challenges

Thanks to their cross-field adaptability, the market demand for high-performance PDMS membranes is on a steady growth trajectory. It is predicted that the global PDMS membrane market size will exceed 5 billion US dollars in 2025, with the liquid separation field accounting for approximately 45% and the energy and electronics field’s share rising to 30%. However, three major challenges remain at present: first, the control of performance uniformity during large-scale production; second, long-term stability under extreme operating conditions (e.g., strong acids and alkalis, high temperature and pressure); third, the persistently high cost of some high-end modified materials.

Dongguan Yusheng Technology Co., Ltd. specializes in the R&D and production of PDMS membranes and offers customized product services. For inquiries, please contact us via email at zhengzhen@nqrubber.com. In the future, through industry-university-research collaborative innovation, optimizing preparation processes, and developing low-cost modifiers, we will promote the industrial application of PDMS membranes in more high-end fields.