Conductive silver adhesive

2025/09/29

0

Core Product Features

Conductive silver adhesive

Basic Properties

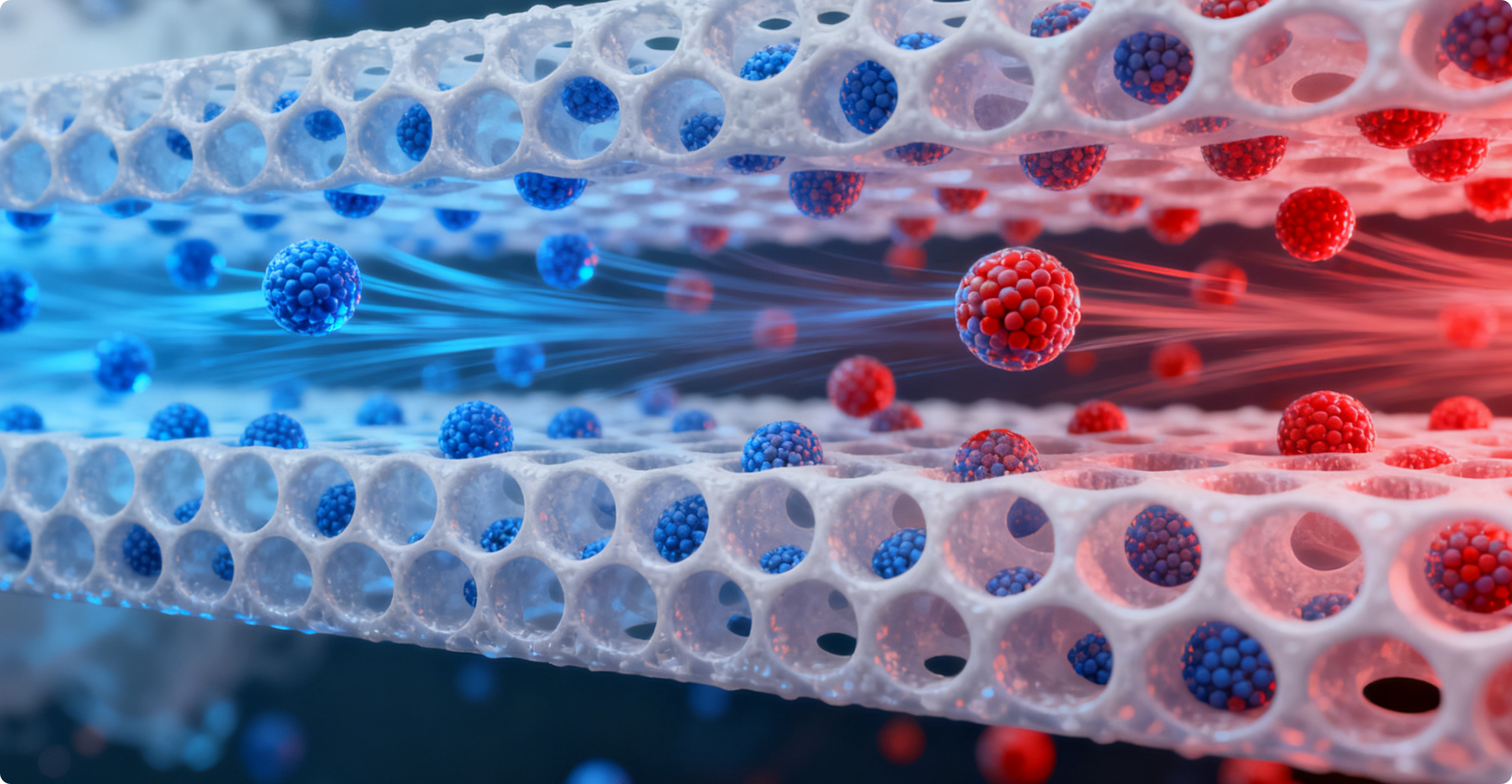

This product is a single-component, low-viscosity conductive silver adhesive. It has passed systematic reliability verification and is suitable for flip-chip bonding of semiconductor chips and precision electronic packaging. Its material system is optimally designed to meet the requirements of high-reliability electronic assembly processes.

Process Characteristics

Through rheological control, the silver adhesive exhibits excellent rheological stability in automated dispensing processes, with a low tailing index and zero stringing phenomenon. This can significantly improve the production efficiency and process yield of SMT (Surface Mount Technology) manufacturing.

Material Performance

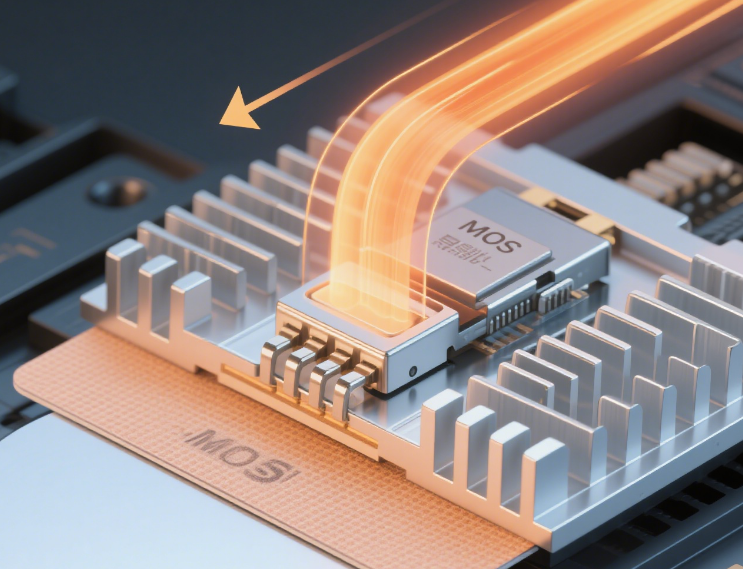

High-purity silver powder and a special polymer matrix are used. During the curing process, it shows an extremely low volume shrinkage rate, which effectively suppresses the interface delamination failure mode and ensures the long-term stability of the packaging structure.

Environmental Adaptability

It has completed comprehensive environmental reliability tests in accordance with the MIL-STD-883 military standard. It can maintain stable physical and chemical properties under harsh environmental conditions such as high-low temperature cycling and humidity aging, making it suitable for high-reliability application scenarios such as aerospace and military electronics.

Application Fields

Widely used in electronic manufacturing fields including:

- Advanced semiconductor packaging (e.g., Flip Chip, COB, etc.)

- MEMS sensor integration

- High-density connector assembly

- Optical communication device packaging

II. Packaging and Storage Specifications

| Category | Technical Requirements |

|---|---|

| Packaging Specifications | Syringe packaging with different volumes from 1CC to 30CC is provided, as well as customized canning solutions, suitable for laboratory R&D and large-scale mass production needs. |

| Storage Conditions | 1. Storage temperature: -40℃±2℃

2. Shelf life: 12 months (unopened) 3. Operating specifications: Avoid repeated freeze-thaw cycles 4. Service life after thawing: Complete dispensing within 18 hours |

III. Detailed Technical Parameters

1. Basic Physical Property Parameters

| Performance Indicator | Test Value | Test Standard |

|---|---|---|

| Appearance | Silver-gray paste | Visual observation |

| Conductive Filler | Nano-scale silver powder | EDS elemental analysis |

| System Composition | Single-component thermosetting system | – |

| Density after Curing | 3.5±0.1 g/cm³ | ASTM D792 |

| Hardness (Shore D) | 75±2 | ASTM D2240 |

| Viscosity (23℃) | 30000±10% cps | Brookfield DV-III |

| Thixotropic Index (TI) | 5.6±0.2 | ISO 2884-1 |

2. Mechanical Performance Parameters

- Chip shear strength (25℃, 2×2mm silicon wafer): ≥20 kgf/die (tested in accordance with JESD22-B117A standard)

3. Thermal Performance Parameters

- Thermal weight loss (TGA, 300℃): ≤1% (heating rate: 10℃/min, N₂ atmosphere)

- Thermal conductivity: 2.5±0.2 W/m・K (tested in accordance with ASTM D5470)

- Coefficient of Thermal Expansion (CTE): 40±2 ppm/℃ (temperature range: 25-150℃)

- Operating temperature range:

- Conventional working conditions: -55℃~200℃

- Short-term overload conditions: -55℃~300℃

4. Electrical Performance Parameters

- Volume resistivity: ≤1×10⁻⁵ Ω・cm (tested 24 hours after curing)

5. Curing Process Parameters

- Recommended curing conditions: 175℃±5℃, constant temperature for 1 hour (heating rate: 5℃/min)