Low-Dielectric Constant Insulating Adhesives: The Invisible Guardians in the Field of Electronic Materials

2025/07/07

0

With the rapid development of electronic technology, electronic products are continuously moving towards miniaturization, integration, and high-speed operation. In this process, low-dielectric constant insulating adhesives, as a key material, play an irreplaceable role. They are like the “invisible guardians” in electronic devices, silently ensuring the efficient transmission of electronic signals and the stable operation of equipment.

I. Definition and Principle of Low-Dielectric Constant Insulating Adhesives

The dielectric constant is a physical quantity measuring the ability of a dielectric to store electrical energy, reflecting the ease with which a material polarizes under an electric field. As the name suggests, low-dielectric constant insulating adhesives are a class of insulating adhesives with relatively low dielectric constants. Their principle is based on the molecular structure and polarization characteristics of the material. Generally, polymer materials with symmetrical molecular structures and fewer polar groups exhibit lower polarization degrees in an electric field, thus showing a lower dielectric constant. For example, polymers such as polytetrafluoroethylene and siloxane are often used as the matrix materials for low-dielectric constant insulating adhesives. The molecular structures of these materials ensure that electrons encounter minimal resistance when moving through them, effectively reducing energy loss and delay during signal transmission.

II. Performance Characteristics of Low-Dielectric Constant Insulating Adhesives

(1) Excellent Dielectric Performance

The most prominent performance of low-dielectric constant insulating adhesives is their low dielectric constant and low dissipation factor (tanδ). In high-frequency circuits, signal transmission speeds are extremely fast. If the dielectric constant of the insulating material is too high, it will cause signal distortion and delay, severely affecting equipment performance. Low-dielectric constant insulating adhesives can significantly reduce signal transmission loss, ensuring signal integrity and accuracy, and providing a guarantee for the normal operation of high-speed electronic devices.

(2) Good Insulation Performance

As insulating adhesives, good insulation performance is their basic requirement. Low-dielectric constant insulating adhesives have high volume resistivity and high breakdown voltage, which can effectively prevent current leakage, avoid faults such as short circuits in electronic devices, and ensure the safety of equipment and personnel.

(3) Good Adhesion and Processability

Low-dielectric constant insulating adhesives need to firmly adhere to various electronic components and substrates, such as ceramics, metals, and glass fiber-reinforced plastics. Meanwhile, they should have good processability, enabling construction through various methods such as coating, printing, and dispensing to meet the needs of different electronic manufacturing processes. Additionally, during the curing process, they should have a low shrinkage rate to avoid damage to electronic components caused by stress from shrinkage.

(4) Good Heat Resistance and Chemical Stability

During the operation of electronic devices, internal heat is generated, and they may also come into contact with various chemical substances. Low-dielectric constant insulating adhesives need to have good heat resistance, capable of working stably for a long time at high temperatures without decomposition or aging. At the same time, they should have good chemical stability, resisting erosion from chemicals such as acids, alkalis, and organic solvents, and ensuring the long-term stability of insulation performance.

III. Preparation Methods of Low-Dielectric Constant Insulating Adhesives

(1) Molecular Structure Design and Modification

Designing and modifying the molecular structure of polymers to reduce the dielectric constant is a common method. For example, introducing large-volume side groups or flexible chain segments into the polymer molecular chain can reduce the close packing between molecules and lower the degree of molecular polarization. Copolymerization, blending, and other means can also be used to combine monomers or polymers with low dielectric constants with other materials with excellent properties to prepare low-dielectric constant insulating adhesives with superior comprehensive performance.

(2) Adding Fillers

Adding low-dielectric constant fillers to the insulating adhesive matrix is also an effective way to reduce the dielectric constant. Commonly used fillers include silica aerogels, boron nitride, talc, etc. These fillers not only have low dielectric constants but also can improve the mechanical and thermal properties of the insulating adhesive. When adding fillers, it is necessary to control the particle size, shape, and dispersibility to ensure the uniform and stable performance of the insulating adhesive.

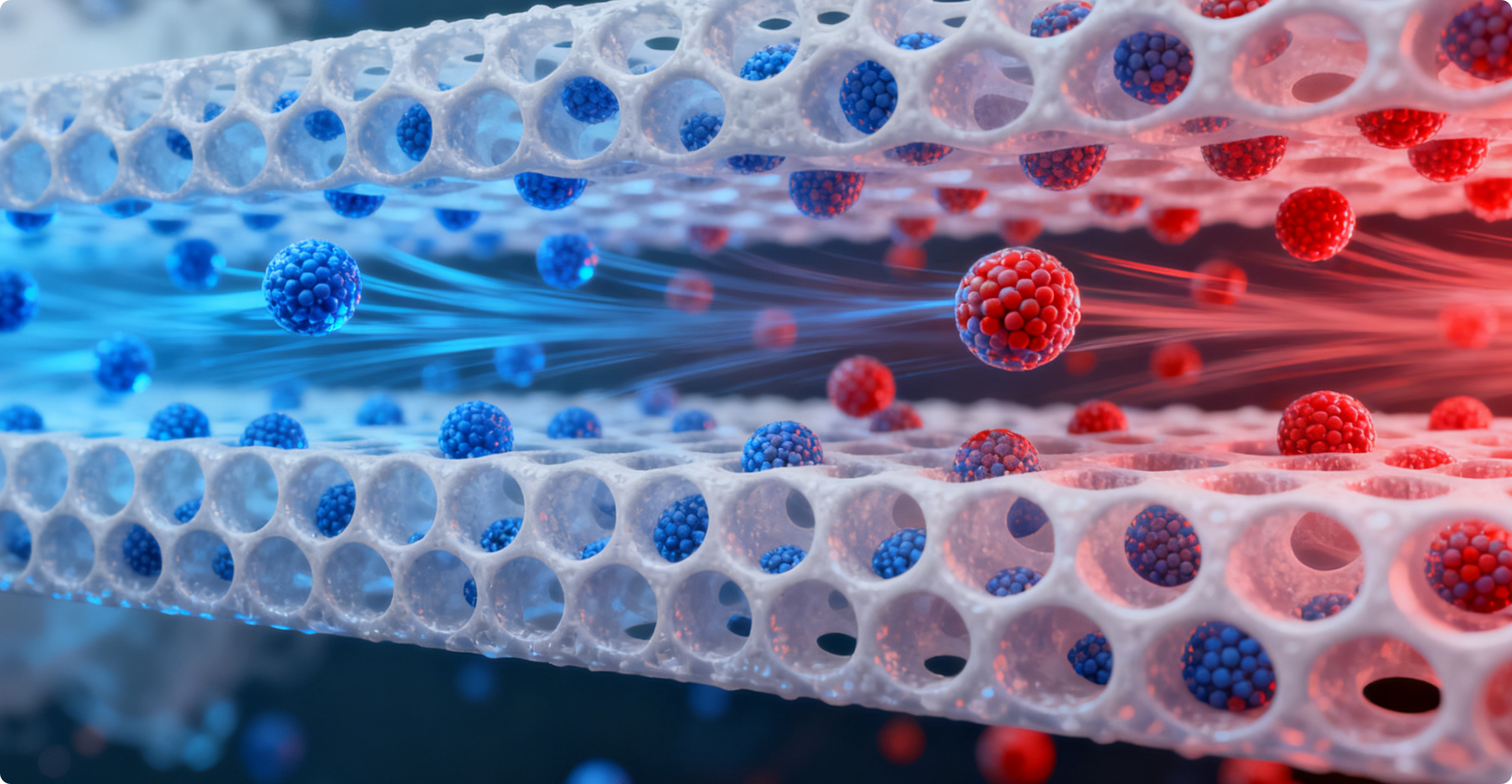

(3) Nano-Composite Technology

With the development of nanotechnology, nano-composite technology has been widely used in the preparation of low-dielectric constant insulating adhesives. Uniformly dispersing nanoscale fillers in the polymer matrix can effectively reduce the dielectric constant without significantly increasing the material density, while also improving the mechanical, thermal, and anti-aging properties of the material. For example, the application of nano-fillers such as nano-silica and nano-montmorillonite has opened up new avenues for improving the performance of low-dielectric constant insulating adhesives.

IV. Application Fields of Low-Dielectric Constant Insulating Adhesives

(1) 5G Communication Field

5G technology, characterized by high speed and low latency, imposes higher requirements on the performance of communication equipment. In 5G base stations, mobile phones, and other communication devices, low-dielectric constant insulating adhesives are widely used for bonding and packaging electronic components. They can effectively reduce signal transmission loss, improve signal transmission speed and quality, and ensure the stable operation of 5G communication.

(2) Integrated Circuit and Semiconductor Field

In the manufacturing process of integrated circuits and semiconductors, low-dielectric constant insulating adhesives are used for bonding and packaging between chips and substrates, as well as interlayer insulation. With the continuous improvement of chip integration, the requirements for the dielectric performance and reliability of insulating materials are also increasing. Low-dielectric constant insulating adhesives can meet these requirements, helping to improve chip performance and reliability while reducing manufacturing costs.

(3) Aerospace Field

Aerospace equipment operates in complex environments, imposing extremely harsh requirements on material performance. Low-dielectric constant insulating adhesives, with their excellent dielectric performance, heat resistance, and chemical stability, are widely used in the insulation, sealing, and bonding of aerospace electronic equipment. They ensure that electronic devices work normally in harsh environments such as high and low temperatures and radiation, safeguarding the smooth completion of aerospace missions.

(4) New Energy Vehicle Field

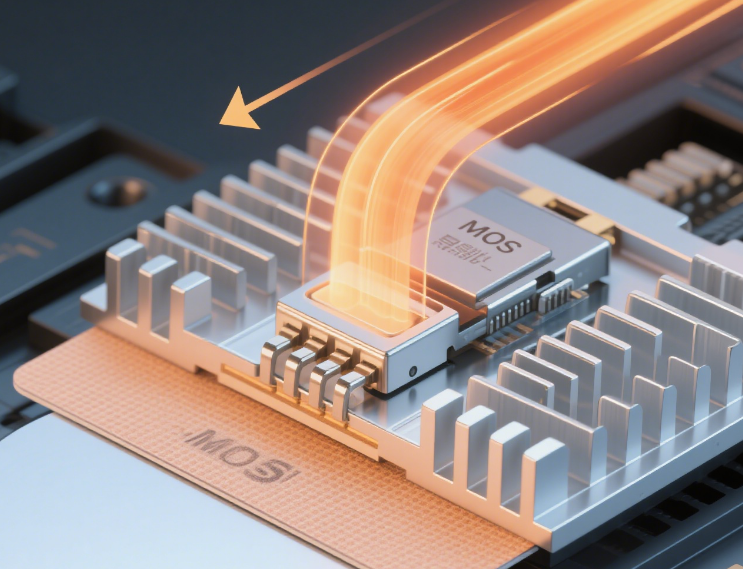

The development of new energy vehicles is inseparable from advanced electronic technology. In key components of new energy vehicles such as battery management systems and motor controllers, low-dielectric constant insulating adhesives are used for insulation, heat dissipation, and fixation. They can effectively improve the reliability and safety of electronic components, extend battery life, and promote the progress of new energy vehicle technology.

V. Development Trends of Low-Dielectric Constant Insulating Adhesives

(1) Lower Dielectric Constant

As electronic technology advances towards higher frequencies and speeds, the requirements for the dielectric performance of low-dielectric constant insulating adhesives are becoming more stringent. In the future, the research and development of insulating adhesive materials with lower dielectric constants will become an important development direction. This requires further in-depth research on the relationship between material molecular structure and dielectric performance, the development of new polymer matrices and fillers, and continuous optimization of preparation processes.

(2) Multifunctionality

Insulating adhesives with single performance can no longer meet the increasingly complex needs of modern electronic devices. In the future, low-dielectric constant insulating adhesives will develop towards multifunctionality, such as simultaneously having high thermal conductivity, high flexibility, self-healing properties, and other multiple performances. By combining materials and technologies with different functions, insulating adhesive products with comprehensive performance advantages will be developed to meet the needs of different application scenarios.

(3) Green and Environmentally Friendly

With the increasing awareness of environmental protection, green and environmental protection has become an inevitable trend in material development. In the production and use of low-dielectric constant insulating adhesives, more attention will be paid to reducing environmental pollution and harm to human health. Developing non-toxic, harmless, and degradable raw materials and adopting green and environmentally friendly preparation processes will be an important direction for the future development of low-dielectric constant insulating adhesives.