Wave-Absorbing Rubber in Diagnostic Equipment

2025/06/27

0

In the field of diagnostic equipment, where precise signal detection and analysis are crucial, wave-absorbing rubber has emerged as a valuable material. This specialized rubber is designed to absorb electromagnetic waves, reducing interference and improving the performance of diagnostic devices.

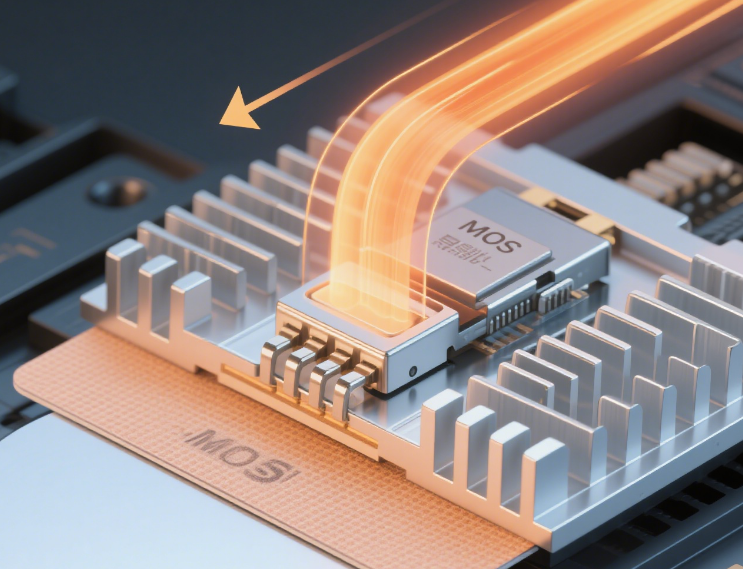

Wave-absorbing rubber is typically composed of a rubber matrix, such as silicone or neoprene, and absorbing fillers, such as ferrite powder, carbonyl iron powder, or conductive polymers. The absorbing fillers are dispersed within the rubber matrix, creating a material that can absorb electromagnetic waves across a wide range of frequencies.

One of the main applications of wave-absorbing rubber in diagnostic equipment is in shielding and isolation. Diagnostic devices are often exposed to electromagnetic interference from external sources, such as radio frequency signals, power lines, and other electronic equipment. By using wave-absorbing rubber gaskets, seals, and panels, manufacturers can create a shielded environment that reduces the impact of electromagnetic interference on the diagnostic signals. This shielding not only improves the accuracy and reliability of the measurements but also helps to prevent false readings and errors.

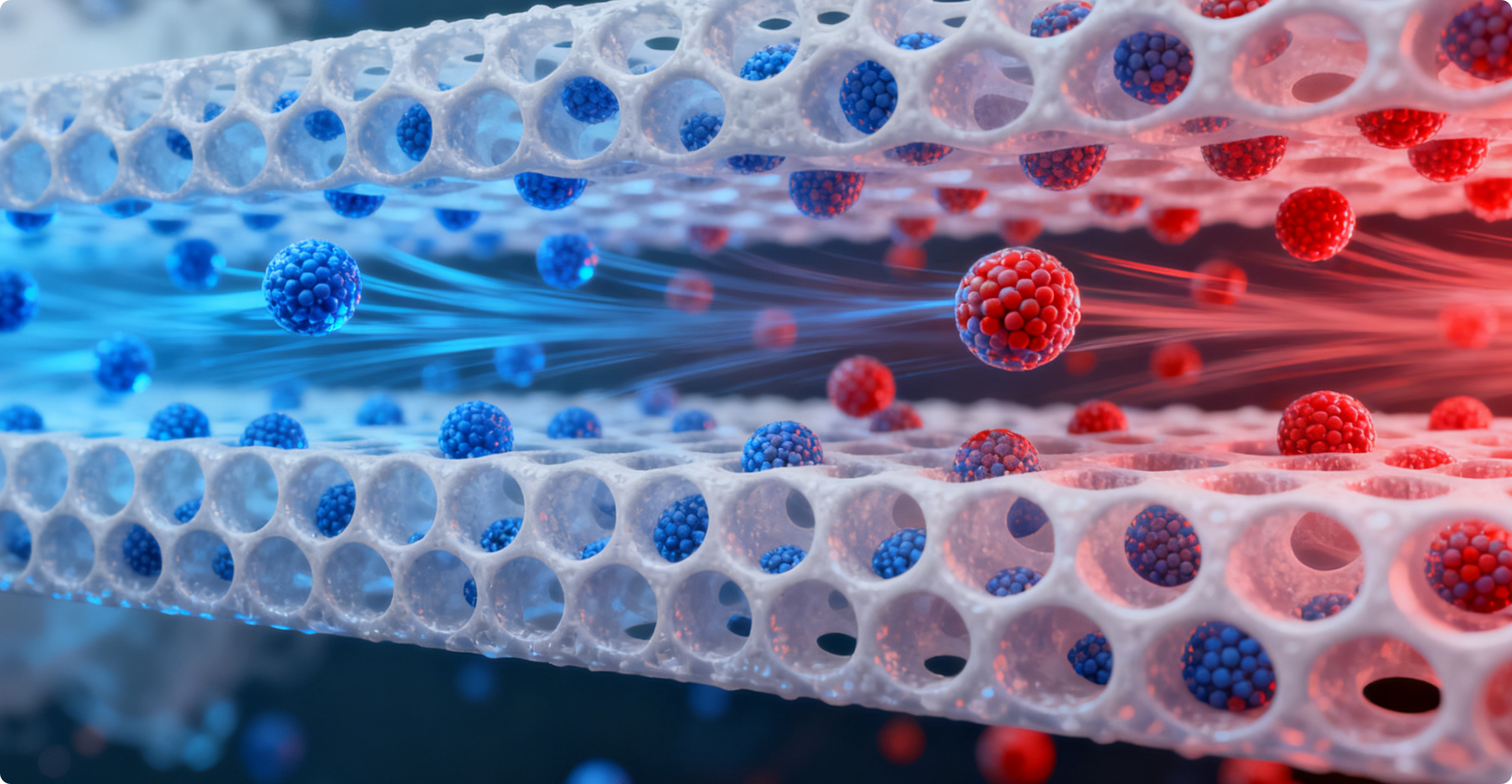

In addition to shielding, wave-absorbing rubber is also used in antenna design and optimization. Antennas are essential components in many diagnostic devices, such as wireless sensors and communication modules. By using wave-absorbing rubber in antenna structures, manufacturers can reduce the reflection and scattering of electromagnetic waves, improving the efficiency and performance of the antennas. This results in better signal reception and transmission, leading to more accurate and reliable diagnostic results.

Another important application of wave-absorbing rubber is in medical imaging equipment, such as MRI scanners and CT scanners. These devices generate strong electromagnetic fields during operation, which can interfere with the imaging process and produce artifacts in the images. By using wave-absorbing rubber in the shielding and isolation of these devices, manufacturers can reduce the interference and improve the quality of the images. This results in more accurate diagnoses and better patient outcomes.

The use of wave-absorbing rubber in diagnostic equipment offers several advantages. Firstly, it helps to improve the accuracy and reliability of diagnostic measurements by reducing electromagnetic interference. This is particularly important in applications where small electrical signals need to be detected and measured accurately, such as in electrocardiography and electroencephalography. Secondly, it helps to improve the performance of antennas and communication modules, leading to better signal reception and transmission. Finally, it helps to improve the quality of medical images, resulting in more accurate diagnoses and better patient outcomes.

However, the use of wave-absorbing rubber also presents some challenges. One of the main challenges is the need to balance absorption performance with other properties, such as flexibility, durability, and cost. Different applications may require different levels of absorption performance, and manufacturers need to select the appropriate type of wave-absorbing rubber based on the specific requirements of the device. Additionally, the long-term performance of wave-absorbing rubber can be affected by factors such as temperature, humidity, and mechanical stress, and manufacturers need to ensure that the rubber can withstand these environmental conditions without losing its absorption properties.

In conclusion, wave-absorbing rubber is a valuable material in modern diagnostic equipment. Its ability to absorb electromagnetic waves reduces interference and improves the performance of diagnostic devices, leading to more accurate and reliable diagnoses. As the demand for more advanced and sensitive diagnostic equipment continues to grow, the development and application of wave-absorbing rubber are likely to become even more important in the future.