Thermal conductive pad in the Field of Unmanned Aerial Vehicles (UAVs)

2025/06/17

0

1. Introduction

Unmanned Aerial Vehicles (UAVs) have witnessed explosive growth in recent years, finding extensive applications in diverse fields such as aerial photography, environmental monitoring, agricultural plant protection, and military reconnaissance. As the complexity and performance requirements of UAVs continue to increase, thermal management has emerged as a critical factor affecting their reliability and lifespan. Among various thermal management solutions, the thermal conductive pad has become an indispensable component, playing a crucial role in ensuring the stable operation of UAVs.

2. Application Scenarios of Thermal Conductive Pads in UAVs

2.1 Electronic Control System

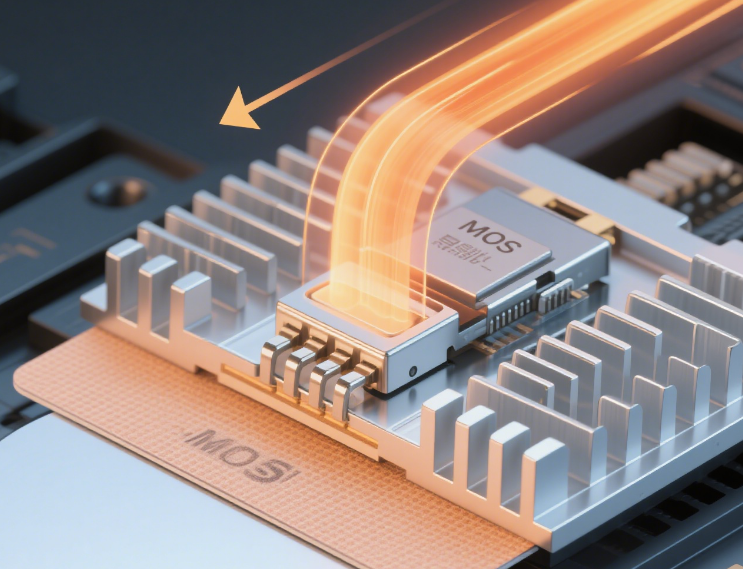

The electronic control system of UAVs, including flight controllers, sensors, and communication modules, generates a significant amount of heat during operation. Components such as microprocessors, integrated circuits, and power amplifiers are particularly heat – intensive. Thermal conductive pads are placed between these heat – generating components and heat sinks or the UAV’s housing. By efficiently transferring heat from the components to the heat dissipation structure, they prevent overheating, which could lead to system failures, inaccurate sensor readings, or communication disruptions. For example, in high – performance flight controllers with multiple cores and high – speed data processing capabilities, thermal conductive pads ensure that the temperature remains within the optimal operating range, enabling the UAV to maintain stable flight control.

2.2 Power System

UAV power systems, mainly composed of batteries and power conversion devices, are also important heat sources. Lithium – ion batteries, commonly used in UAVs, are sensitive to temperature. High temperatures can reduce battery capacity, shorten battery life, and even pose safety risks such as thermal runaway. Thermal conductive pads are applied to the battery pack to transfer the heat generated during charging and discharging to the UAV’s heat – dissipation channels. In addition, power conversion modules like DC – DC converters and motor drivers generate heat during the process of converting and regulating electrical energy. Thermal conductive pads help these modules dissipate heat effectively, improving the overall efficiency and reliability of the power system.

2.3 Motor and Drive System

The motors and drive systems of UAVs are key components for flight propulsion. During operation, electric motors generate heat due to internal resistance and mechanical friction, and the drive circuits also produce heat. Thermal conductive pads are used to transfer the heat from the motor housing and drive circuit boards to heat – dissipating fins or the UAV’s frame. This helps to maintain the normal operating temperature of the motor and drive system, preventing performance degradation and potential failures, thus ensuring the stable flight performance of the UAV.

3. Performance Advantages of Thermal Conductive Pads in UAVs

3.1 High Thermal Conductivity

Thermal conductive pads with high thermal conductivity are capable of quickly and effectively transferring heat from heat – generating components to heat – dissipation media. This high – efficiency heat transfer helps to lower the temperature of key components, reducing the risk of thermal stress – induced damage and improving the overall thermal management efficiency of UAVs. Compared with traditional thermal management materials, high – thermal – conductivity thermal conductive pads can achieve better heat – dissipation results in a limited space, which is especially important for UAVs with strict size and weight requirements.

3.2 Good Compressibility and Conformability

UAVs are often designed with compact internal structures, and there may be uneven surfaces between components and heat – dissipation structures. Thermal conductive pads have excellent compressibility and conformability. They can be easily compressed to fill the gaps and irregularities between components, ensuring a close contact and good thermal interface. This not only maximizes heat transfer but also helps to isolate mechanical vibrations between components, reducing the impact of vibrations on the performance and lifespan of UAV components.

3.3 Insulation and Electrical Safety

In the electrical – intensive environment of UAVs, thermal conductive pads usually have good electrical insulation properties. This insulation ensures that there is no short – circuit risk between different electrical components during the heat – transfer process, safeguarding the electrical safety of the UAV system. It also prevents electrical interference, ensuring the normal operation of sensitive electronic devices such as sensors and communication modules.

3.4 Lightweight and Durable

UAVs have strict requirements for component weight to increase flight time and payload capacity. Thermal conductive pads are relatively lightweight, adding minimal additional weight to the UAV. At the same time, they have good durability and can maintain stable thermal – conductive performance over a long period under various environmental conditions, including high – temperature, low – temperature, humidity, and vibration. This durability reduces the maintenance and replacement frequency of UAV thermal management components, improving the overall reliability and cost – effectiveness of UAVs.

4. Challenges and Solutions for Thermal Conductive Pads in UAVs

4.1 Harsh Environmental Conditions

UAVs often operate in harsh environments, such as high – altitude, low – temperature, high – temperature, and high – humidity conditions. In low – temperature environments, the thermal conductivity and flexibility of thermal conductive pads may decrease, affecting their heat – dissipation performance. In high – temperature environments, thermal conductive pads may age or degrade more rapidly, losing their original performance. To address these issues, the development of thermal conductive pads with a wide operating temperature range is crucial. Materials with enhanced low – temperature flexibility and high – temperature stability, such as special silicone – based or fluoropolymer – based thermal conductive pads, are being explored and applied.

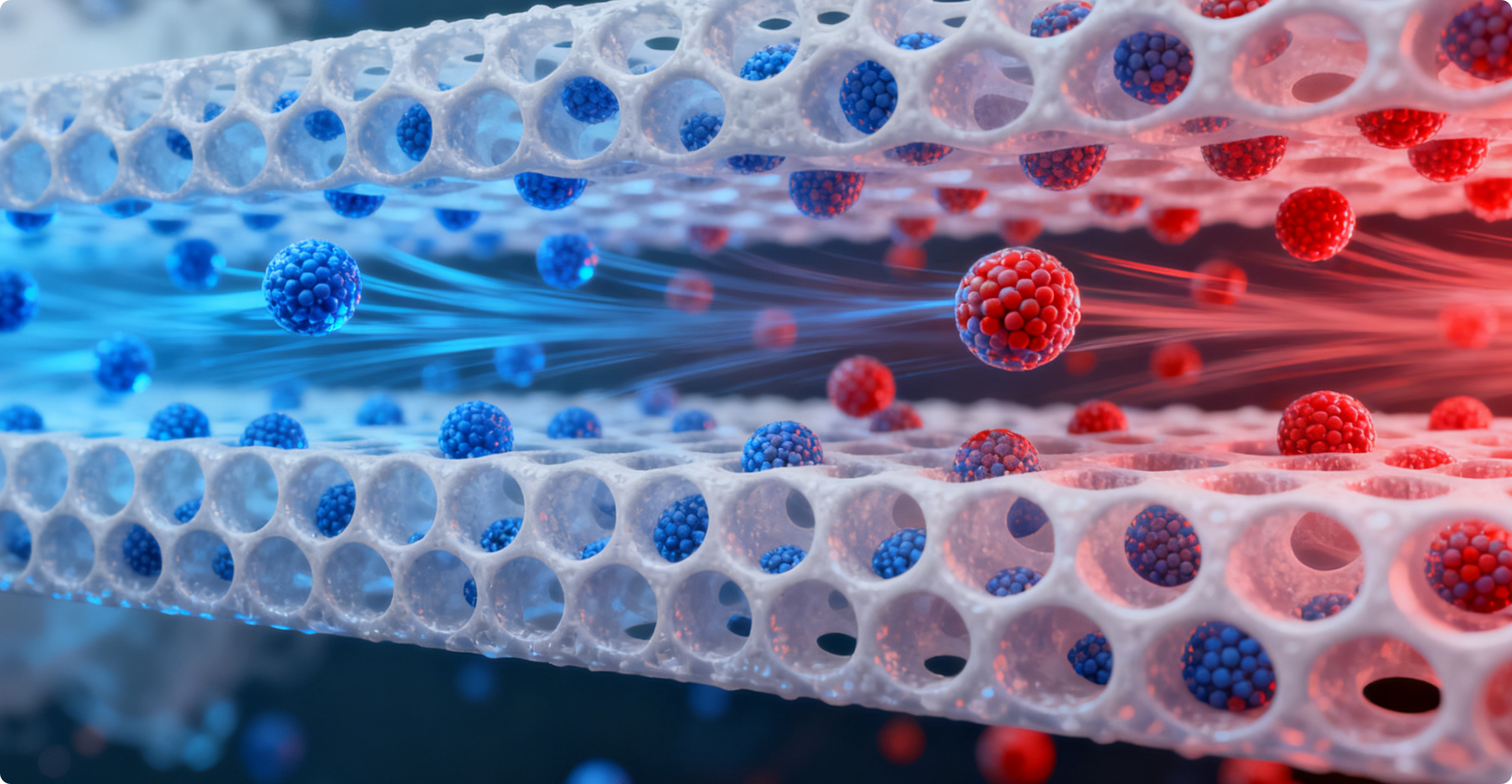

4.2 Miniaturization and High – Integration Requirements

As UAVs tend to be more miniaturized and highly integrated, the available space for thermal management is becoming increasingly limited. This requires thermal conductive pads to have higher thermal conductivity per unit volume and better adaptability to complex and compact internal structures. Advanced manufacturing techniques, such as nanocomposite technology, are being used to develop thinner and more efficient thermal conductive pads. These pads can achieve excellent heat – transfer performance while occupying less space, meeting the requirements of UAV miniaturization and high – integration.

4.3 Cost – Effectiveness

The cost of thermal conductive pads also affects their widespread application in UAVs. While high – performance thermal conductive pads can provide better thermal management, they may come with a relatively high cost. To balance performance and cost, manufacturers are exploring ways to optimize the production process, use more cost – effective raw materials, and improve the mass – production efficiency of thermal conductive pads. At the same time, research on alternative materials and innovative thermal – conductive pad designs is ongoing to develop more cost – effective thermal management solutions for UAVs.

5. Future Development Trends

5.1 Development of New Materials

With the continuous progress of materials science, new materials with better thermal – conductive, mechanical, and environmental – resistance properties will be developed for thermal conductive pads. For example, the application of nanomaterials such as graphene and carbon nanotubes in thermal conductive pads is expected to significantly improve their thermal conductivity and other performance indicators, providing more efficient thermal management solutions for UAVs.

5.2 Intelligent Thermal Management

The future of thermal conductive pads in UAVs may be integrated with intelligent thermal management systems. These systems can dynamically adjust the thermal – conductive performance of thermal conductive pads according to the real – time temperature and operating conditions of UAV components. For example, through the use of shape – memory materials or thermally responsive polymers in thermal conductive pads, the contact area and thermal conductivity can be adjusted automatically, achieving more precise and energy – efficient thermal management.

5.3 Integration with Other Components

Thermal conductive pads may be further integrated with other UAV components in the future. For instance, they could be combined with heat – dissipation structures, electronic components, or even the UAV’s frame design. This integration can simplify the UAV’s internal structure, improve assembly efficiency, and enhance the overall thermal management performance while reducing the weight and cost of the UAV.

6. Conclusion

Thermal conductive pads play a vital role in the thermal management of UAVs, ensuring the stable operation of key components in electronic control systems, power systems, and motor and drive systems. Their high thermal conductivity, good compressibility, insulation properties, and lightweight and durable characteristics provide significant performance advantages. However, they also face challenges in harsh environmental conditions, miniaturization requirements, and cost – effectiveness. Looking ahead, with the development of new materials, the trend towards intelligent thermal management, and greater integration with other components, thermal conductive pads will continue to evolve and contribute to the improvement of UAV performance, reliability, and functionality.