Wave-absorbing Rubber in Medical Equipment

2025/06/16

0

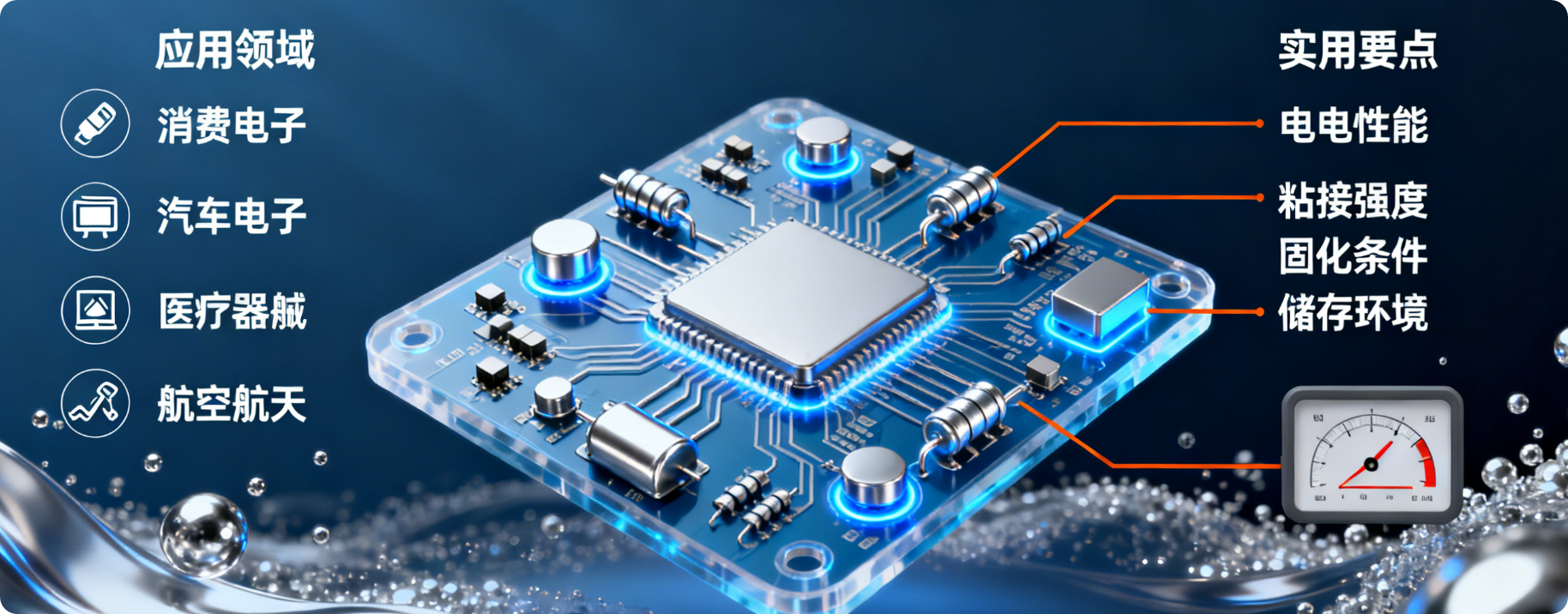

Wave-absorbing rubber, also known as microwave absorbing rubber or electromagnetic wave absorbing rubber, is a special type of rubber material that can absorb electromagnetic waves, converting electromagnetic energy into heat energy through internal loss mechanisms and dissipating it, thereby reducing electromagnetic wave reflection and interference. In recent years, with the continuous development and increasing complexity of medical equipment, wave-absorbing rubber has played an increasingly important role in the field of medical devices.

Characteristics of Wave-absorbing Rubber

Wave-absorbing rubber combines the excellent flexibility, wear – resistance, and processability of rubber with the wave-absorbing properties. It can be customized to have different wave-absorbing frequencies and absorption efficiencies according to specific needs. The rubber matrix provides good mechanical properties, ensuring that the material can adapt to various complex shapes and application environments in medical equipment. Additionally, it has good chemical stability, which can resist the corrosion of common medical disinfectants and cleaning agents, ensuring long-term reliable use in the medical environment.

Applications in Medical Equipment

Magnetic Resonance Imaging (MRI) Systems

In MRI machines, strong magnetic fields and radiofrequency pulses are used to generate detailed images of the human body. However, electromagnetic interference can seriously affect the quality of the imaging. Wave-absorbing rubber is applied to the interior of MRI cabinets and around sensitive components. It absorbs stray electromagnetic waves, reducing interference within the system. This ensures that the MRI can produce high-resolution and accurate images, which is crucial for the diagnosis of various diseases, such as brain tumors, joint problems, and cardiovascular diseases.

Medical Sensors

Medical sensors, such as those used for monitoring vital signs like heart rate, blood pressure, and body temperature, are becoming more and more miniaturized and intelligent. These sensors are easily affected by external electromagnetic waves, which may lead to inaccurate measurement results. Wave-absorbing rubber can be used as a protective coating or encapsulation material for sensors. By absorbing external electromagnetic interference, it helps the sensors to accurately and stably collect physiological data, providing reliable information for medical diagnosis and treatment.

Medical Communication Equipment

With the development of telemedicine, medical communication equipment, such as wireless patient monitors and remote diagnosis devices, has been widely used. Wave-absorbing rubber is used in the housing and antenna parts of these devices. It can improve the signal quality, reduce signal loss and interference, ensuring stable communication between medical staff and patients, whether in the hospital or in remote areas. This is of great significance for timely medical treatment and emergency response.

Surgical Equipment

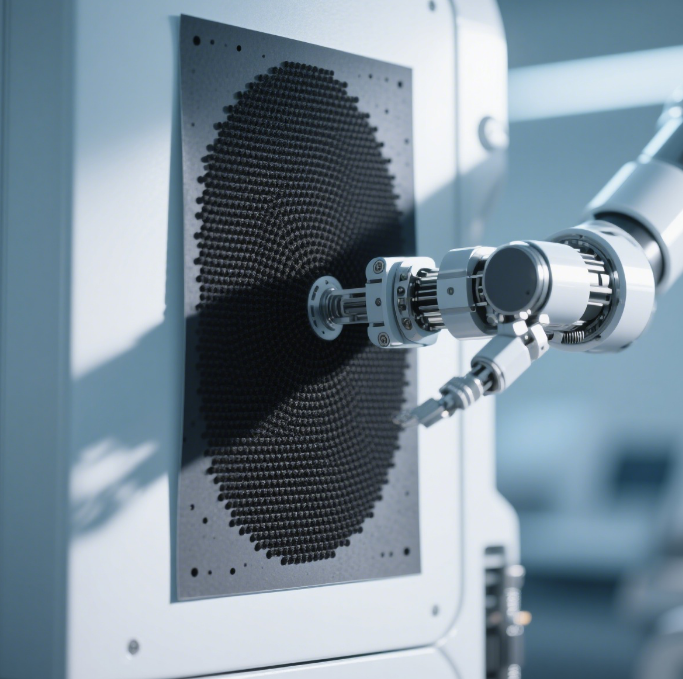

Some advanced surgical equipment, such as minimally invasive surgical robots and laser surgical devices, contains a large number of electronic components. Wave-absorbing rubber is used to isolate these components from electromagnetic interference, ensuring the normal operation of the equipment during surgery. This helps surgeons to perform operations more accurately and safely, reducing the risk of surgical complications.

Advantages of Using Wave-absorbing Rubber in Medical Equipment

Improved Equipment Performance

By reducing electromagnetic interference, wave-absorbing rubber significantly improves the performance and reliability of medical equipment. This leads to more accurate diagnostic results, more stable monitoring data, and more precise surgical operations, ultimately benefiting patient treatment.

Enhanced Patient Safety

Since electromagnetic interference may cause malfunctions in medical equipment, which poses a potential threat to patient safety, the use of wave-absorbing rubber can eliminate this risk. It ensures that medical equipment operates stably and safely during the entire treatment process, protecting the health and safety of patients.

Extended Equipment Lifespan

Excessive electromagnetic interference can accelerate the aging of electronic components in medical equipment. Wave-absorbing rubber helps to reduce the impact of electromagnetic waves on components, thereby extending the service life of medical equipment and reducing the cost of equipment replacement and maintenance for medical institutions.

Challenges and Future Developments

Although wave-absorbing rubber has many advantages in medical equipment applications, there are still some challenges. For example, in some high-frequency and high-intensity electromagnetic environments, the wave-absorbing performance of existing wave-absorbing rubber may not be sufficient. In addition, the cost of high-performance wave-absorbing rubber is relatively high, which limits its wider application to a certain extent.

In the future, research and development efforts will focus on improving the wave-absorbing performance of rubber materials in a wider frequency range and under more complex electromagnetic environments. At the same time, exploring more cost-effective production processes and raw materials to reduce the cost of wave-absorbing rubber is also an important direction. With the continuous progress of material science and the increasing demand for high-quality medical equipment, wave-absorbing rubber is expected to play an even more important role in the medical field.