silicone sealant in satellite communication equipment

2025/06/16

0

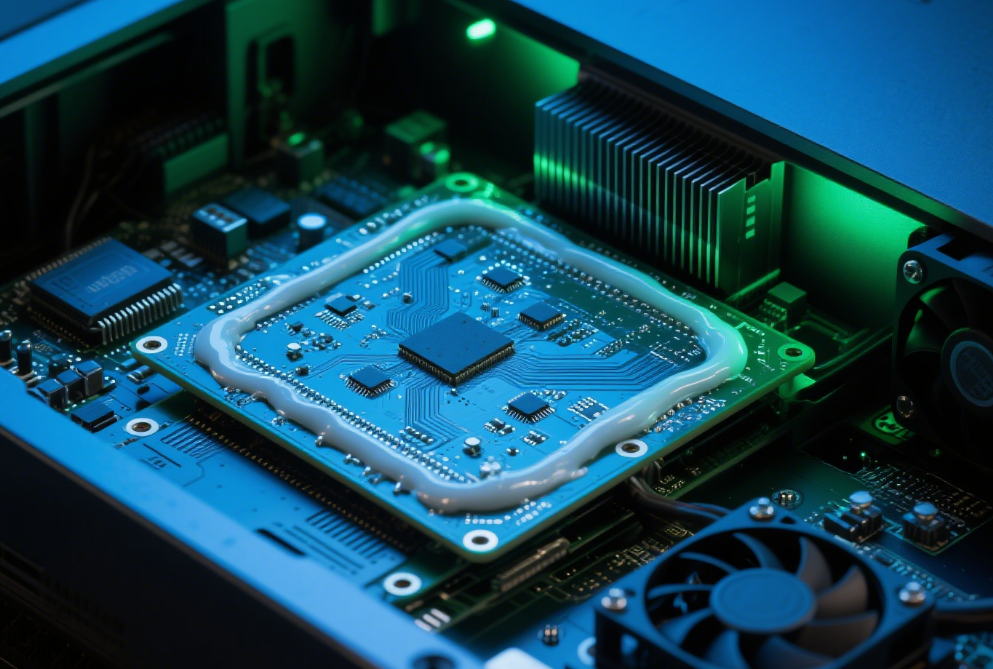

Protection Against EMI/RFI

One of the most significant problems in satellite communication is EMI/RFI, which can severely disrupt signal transmission. Silicone sealants, especially those with electrically conductive properties, play a vital role in this regard. Conductive silicone sealants can be used as gasketing materials. They create a continuous conductive path around sensitive components, effectively preventing the ingress and egress of electromagnetic and radio frequency signals. This helps in maintaining the integrity of the communication signals, reducing signal degradation, and ensuring that the satellite can transmit and receive data accurately. For example, in satellite antennas, where precise signal reception and transmission are crucial, EMI/RFI – shielding silicone gaskets are used to isolate the antenna components from external electromagnetic interference. These gaskets can be custom – molded, calendered into sheets, or die – cut to fit specific applications within the satellite communication equipment.

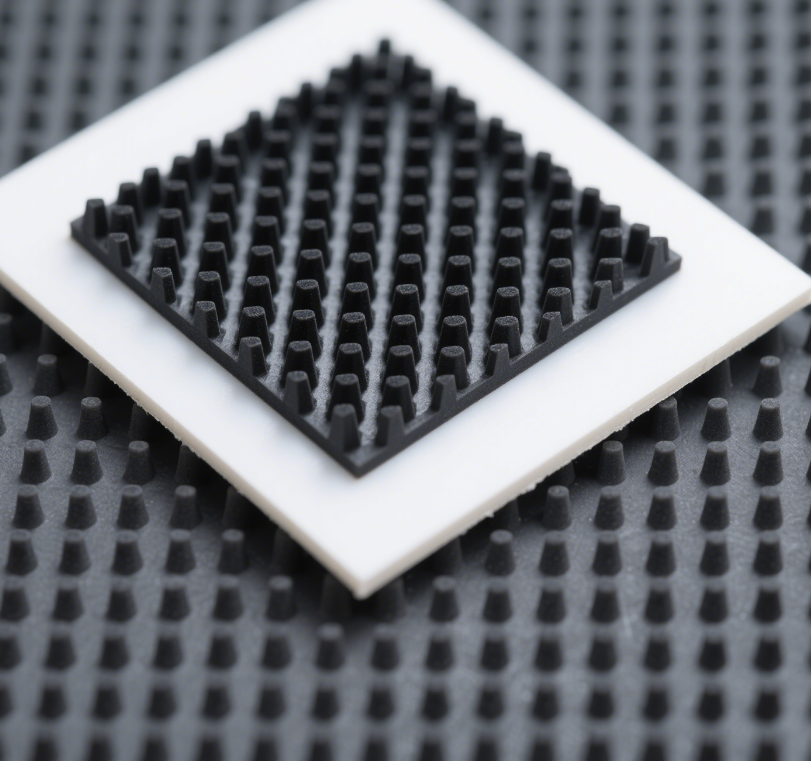

Thermal Management

Satellite components generate heat during operation, and efficient thermal management is essential to prevent overheating, which can lead to component failure. Thermally conductive silicone sealants are employed to transfer heat away from sensitive components. In satellite communication equipment, such as high – power amplifiers and signal processors, heat build – up can be a major issue. The thermally conductive silicone sealant acts as a heat transfer medium, conducting heat from the heat – generating components to a heat sink or other cooling elements. This ensures that the components operate within their optimal temperature range, enhancing their reliability and lifespan. Some thermally conductive silicone sealants can dissipate heat efficiently even in the extreme temperature conditions encountered in space, where temperatures can range from extremely cold in shadowed regions to very hot when exposed to the sun.

Resistance to Extreme Environments

Temperature Resistance

Satellites experience a wide range of temperatures, from the cold depths of space (as low as – 270°C in some cases) to the intense heat of solar radiation (up to several hundred degrees Celsius). Silicone sealants are known for their excellent high – temperature and low – temperature resistance. They can maintain their physical and chemical properties over a broad temperature range. In the cold of space, silicone sealants do not become brittle and retain their flexibility, ensuring that seals remain intact. In high – temperature environments, they do not melt or decompose, continuing to provide effective sealing and protection. This temperature stability is crucial for the long – term operation of satellite communication equipment.

UV and Radiation Resistance

In space, satellite communication equipment is constantly exposed to high – energy ultraviolet (UV) radiation from the sun and other forms of ionizing radiation. Silicone sealants are highly resistant to UV light, as they are proven to be UV – light stable. This property makes them an ideal choice for applications where exposure to UV light is unavoidable, such as in the external components of satellites. Additionally, silicone sealants can withstand high levels of ionizing radiation. The molecular structure of silicone is relatively stable under radiation, which helps in maintaining the integrity of the sealant and the equipment it protects. This resistance to radiation is important as radiation can cause degradation in many materials, leading to loss of performance in satellite communication systems.

Chemical and Flame Resistance

Satellite communication equipment may come into contact with various chemicals during launch, deployment, and operation. Silicone sealants resist a wide range of chemicals, protecting the equipment from chemical corrosion. In addition, they are often flame – retardant, which is a crucial safety feature. In the event of an electrical short or other potential fire – starting incidents within the satellite, the flame – retardant properties of the silicone sealant can prevent the spread of fire, minimizing damage to the communication equipment and the overall satellite.

Durability and Longevity

Satellites are designed to operate for long periods, often years or even decades, in space. Silicone sealants offer enhanced durability, providing increased longevity and reduced maintenance needs. They can withstand the mechanical stresses and vibrations experienced during launch and the continuous thermal cycling in orbit. The low – modulus nature of some silicone sealants allows them to relieve stress effectively when materials expand or contract due to temperature changes. This ability to absorb stress helps in preventing cracks and failures in the seals, ensuring that the components can withstand the rigors of normal operations without frequent replacement. This is particularly important for satellite communication equipment, where maintenance is extremely difficult and costly, often requiring complex and expensive space missions.

Customizability

Silicone sealants can be tailored to fit specific application needs in satellite communication equipment. Manufacturers can adjust the formulation of the silicone to achieve custom shapes, sizes, and properties. For example, they can control the hardness, viscosity, and curing time of the sealant to meet the exacting specifications of different satellite components. This customizability allows for the creation of highly specialized sealants that are optimized for specific functions within the satellite communication system, whether it is sealing a small electronic module or providing a large – scale structural seal.

In conclusion, silicone sealant is an indispensable material in satellite communication equipment. Its unique combination of properties, including EMI/RFI shielding, thermal management capabilities, resistance to extreme environments, durability, and customizability, makes it essential for ensuring the reliable and long – term operation of satellite communication systems. As the demand for more advanced and reliable satellite communication continues to grow, the role of silicone sealants will only become more critical in the development of future – generation satellite technology.