wave-absorbing rubber in satellite communication equipment

2025/06/16

0

In the realm of satellite communication equipment, where the transmission and reception of signals are paramount, wave – absorbing rubber has emerged as a crucial component. This specialized material plays a vital role in enhancing the performance and reliability of satellite communication systems through its unique properties and diverse applications.

1. Properties of Wave – absorbing Rubber

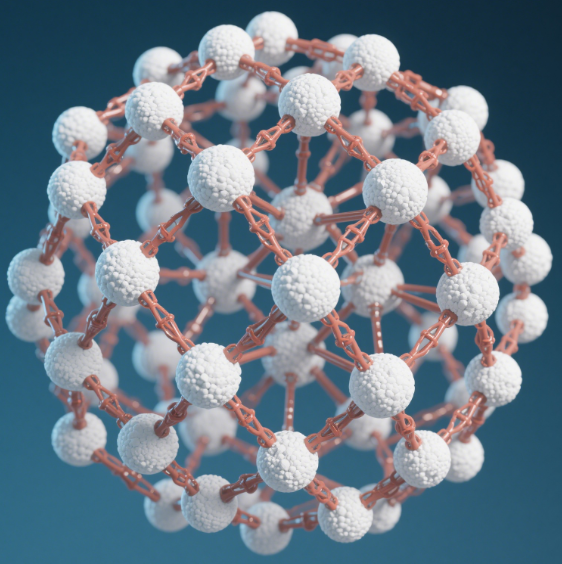

Wave – absorbing rubber is a composite material that combines the flexibility and processability of rubber with the electromagnetic wave – absorbing capabilities of additives. The rubber matrix serves as a binder, providing mechanical strength, flexibility, and durability, while the wave – absorbing additives, such as ferrite powders, carbonyl iron particles, or conductive polymers, are responsible for the absorption of electromagnetic waves.

The wave – absorbing mechanism of this rubber is based on the conversion of electromagnetic wave energy into heat energy through various physical and chemical processes. When electromagnetic waves interact with the wave – absorbing rubber, the additives within the material cause the waves to be scattered, reflected, and absorbed. The absorbed energy is then dissipated as heat, reducing the intensity of the electromagnetic waves and minimizing interference.

One of the key advantages of wave – absorbing rubber is its ability to operate over a wide frequency range. Different types of wave – absorbing rubber can be designed to absorb electromagnetic waves in specific frequency bands, making them suitable for various satellite communication applications. Additionally, wave – absorbing rubber has good flexibility and can be easily molded into different shapes and sizes, allowing for seamless integration into satellite communication equipment.

2. Applications in Satellite Communication Equipment

2.1 Antenna Systems

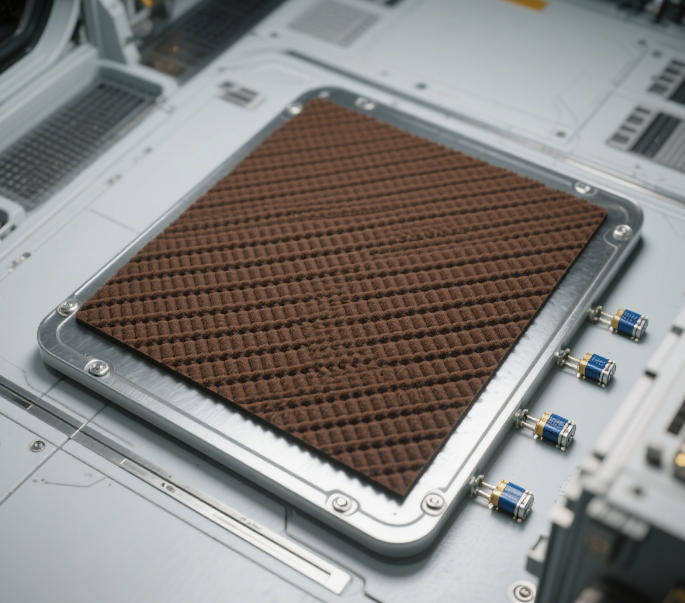

Antennas are the primary components of satellite communication systems, responsible for transmitting and receiving electromagnetic signals. However, antennas are also susceptible to electromagnetic interference, which can degrade the quality of the communication signals. Wave – absorbing rubber is widely used in antenna systems to reduce electromagnetic interference and improve the performance of the antennas.

By applying wave – absorbing rubber to the surfaces of antennas or the surrounding structures, the amount of electromagnetic wave reflection and scattering can be significantly reduced. This helps to minimize interference between different antennas on the satellite and improves the overall efficiency of the antenna system. For example, in multi – antenna satellite systems, wave – absorbing rubber can be used to isolate the antennas from each other, preventing signal crosstalk and enhancing the signal – to – noise ratio.

2.2 Electronic Enclosures

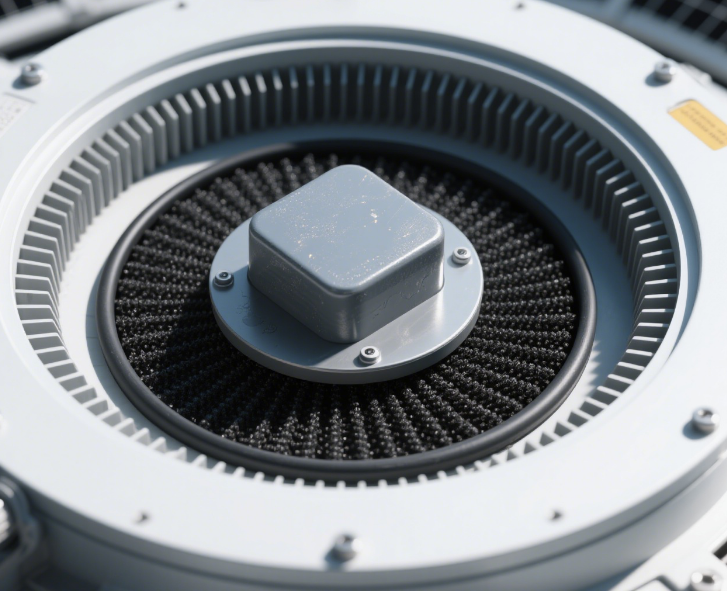

Satellite communication equipment contains a large number of electronic components, which generate electromagnetic radiation during operation. This electromagnetic radiation can interfere with other electronic components on the satellite and also pose a risk of electromagnetic interference to other satellites or ground – based communication systems. Wave – absorbing rubber is used to line the interiors of electronic enclosures to absorb the electromagnetic radiation emitted by the electronic components, reducing electromagnetic interference and protecting the sensitive electronic devices.

The use of wave – absorbing rubber in electronic enclosures also helps to improve the electromagnetic compatibility (EMC) of the satellite communication equipment. EMC refers to the ability of electronic equipment to operate without interfering with other electronic devices in the same electromagnetic environment. By reducing electromagnetic radiation and interference, wave – absorbing rubber ensures that the satellite communication equipment can operate smoothly and reliably in the complex electromagnetic environment of space.

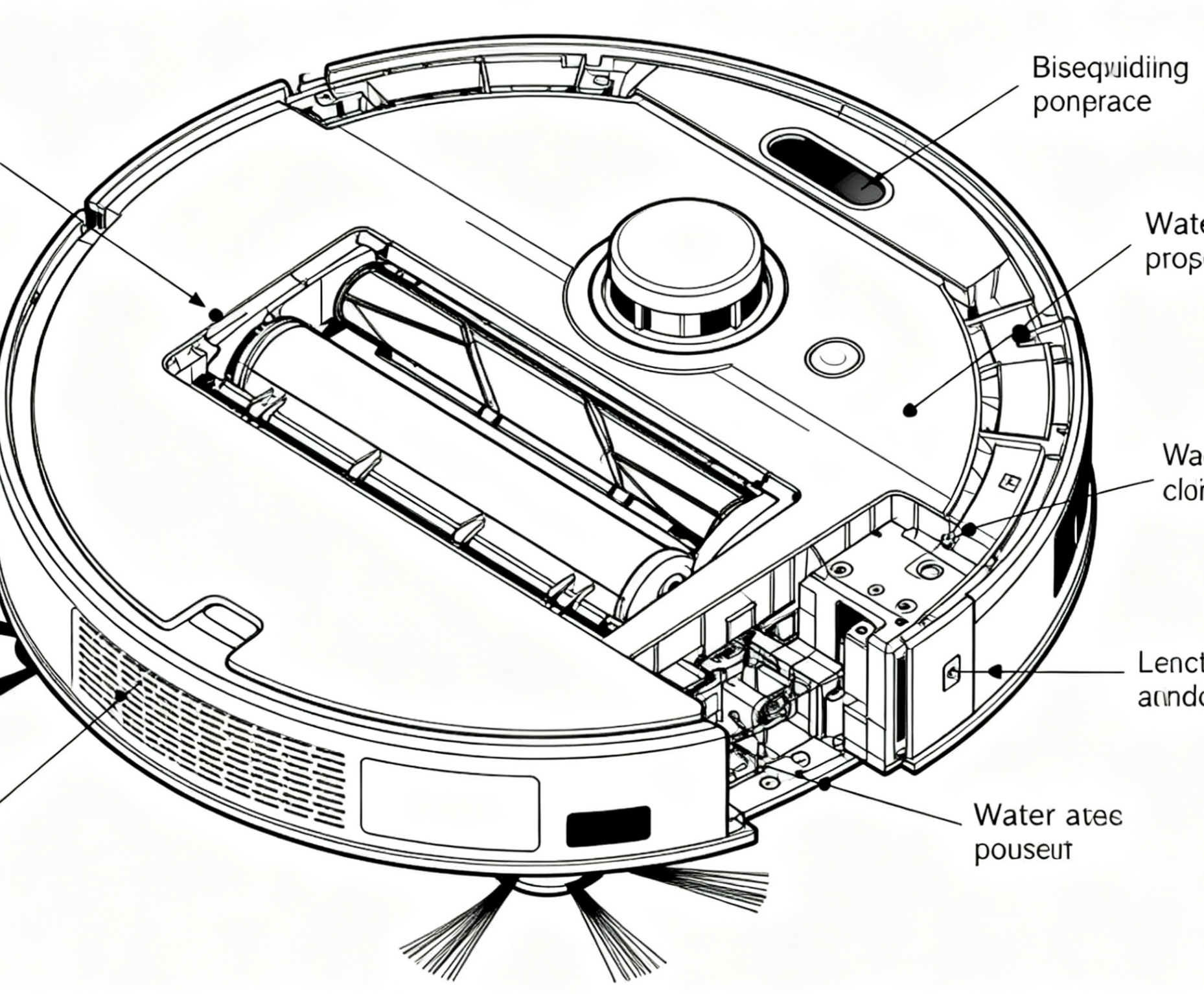

2.3 Cable and Connector Systems

Cables and connectors are essential for transmitting electrical signals within satellite communication equipment. However, they can also act as antennas, radiating electromagnetic waves and causing interference. Wave – absorbing rubber can be used to wrap around cables or applied to the surfaces of connectors to suppress electromagnetic radiation and reduce interference.

In addition, wave – absorbing rubber can also improve the mechanical protection of cables and connectors. The flexibility and durability of the rubber provide cushioning and protection against mechanical stress, vibration, and shock, ensuring the reliable operation of the cable and connector systems in the harsh environment of space.

3. Future Developments

As satellite communication technology continues to evolve, the demand for high – performance wave – absorbing rubber is expected to increase. Future developments in wave – absorbing rubber for satellite communication equipment are likely to focus on the following areas:

3.1 Broadband Absorption

With the increasing use of high – frequency and broadband satellite communication systems, there is a growing need for wave – absorbing rubber that can operate over a wider frequency range. Researchers are exploring new materials and manufacturing techniques to develop wave – absorbing rubber with broadband absorption capabilities, enabling it to effectively absorb electromagnetic waves across multiple frequency bands.

3.2 Lightweight and Thin – film Materials

Satellites have strict weight and size constraints, and reducing the weight and thickness of wave – absorbing rubber without sacrificing its performance is a key challenge. Future research will focus on developing lightweight and thin – film wave – absorbing rubber materials that can be easily integrated into satellite communication equipment while providing excellent wave – absorbing performance.

3.3 Self – healing and Smart Materials

In the harsh environment of space, wave – absorbing rubber may be subject to damage from radiation, micrometeoroids, and other factors. The development of self – healing wave – absorbing rubber materials that can repair themselves when damaged will improve the reliability and lifespan of satellite communication equipment. Additionally, smart wave – absorbing rubber materials that can adjust their wave – absorbing properties in response to changes in the electromagnetic environment are also an area of active research.

In conclusion, wave – absorbing rubber is an indispensable material in satellite communication equipment. Its unique properties and diverse applications make it crucial for enhancing the performance, reliability, and electromagnetic compatibility of satellite communication systems. With the continuous development of satellite communication technology, wave – absorbing rubber is expected to play an even more important role in the future, enabling the development of more advanced and efficient satellite communication systems.