Application of Silicone Conductive Rubber in Communication Equipment

2025/06/13

0

I. Electromagnetic Shielding

(1) Communication Cabinets

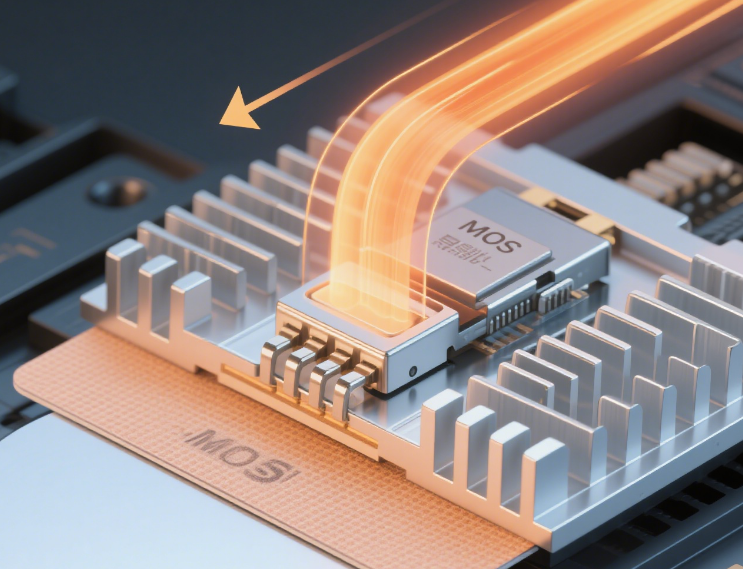

In modern communication networks, communication cabinets play a crucial role in housing and protecting core communication equipment. However, electronic devices generate electromagnetic interference (EMI) during operation and are also vulnerable to external electromagnetic signals. Silicon conductive rubber has become an ideal material for sealing gaps in communication cabinets due to its excellent electromagnetic shielding performance. Installed in door seams, ventilation holes, and other parts of the cabinet, it forms a continuous conductive shielding layer to restrict EMI within the cabinet or block external interference sources, ensuring the normal operation of internal electronic devices.

Take the high-conductivity silicone rubber from nqrubber as an example. It has an extremely low volume resistivity, enabling efficient reflection and absorption of electromagnetic energy to achieve a shielding effectiveness of up to 80 dB or more. When applied in communication cabinets of large data centers, it can effectively reduce electromagnetic crosstalk between servers, enhancing the accuracy and stability of data transmission. Moreover, this silicon conductive rubber has good weather resistance, maintaining stable shielding performance and sealing effect for a long time even in 机房 (server room) environments with large temperature differences and high humidity.

(2) Base Station Equipment

Conductive silicone rubber is used in communication cabinets to play the role of electromagnetic shielding.

As a key node in wireless communication networks, base stations integrate numerous precise electronic components and complex circuit boards. During the transmission and processing of high-frequency signals, EMI is highly likely to generated, which not only reduces the signal quality of the base station itself but may also adversely affect surrounding communication equipment. Silicon conductive rubber constructs a comprehensive electromagnetic shielding system by sealing and shielding the joints of the base station equipment’s housing, circuit board interfaces, and other positions.

For example, in 5G base stations, due to the characteristics of high-frequency signal transmission, the requirements for electromagnetic shielding are more stringent. Shielding gaskets made of silicon conductive rubber can closely fit the metal housing of base station equipment, block electromagnetic leakage paths, and control EMI within a safe range. Meanwhile, it can prevent the impact of strong electromagnetic environments such as external electromagnetic pulses and lightning on base station equipment, ensuring the 24-hour stable operation of the base station and providing high-quality communication services to users.

II. Circuit Connection

Conductive silicone rubber is used in communication cabinets to play the role of electromagnetic shielding.

(1) Buttons

The buttons of portable communication devices such as mobile phones and walkie-talkies are important interfaces for users to interact with the devices. Silicon conductive rubber buttons are widely used because they achieve circuit conduction while providing a comfortable touch and stable conductive performance. When a user presses a button, the conductive fillers inside the silicon conductive rubber come into contact with each other, forming a conductive path to accurately transmit the button operation signal to the internal circuit of the device.

Take a smartphone as an example: its buttons need to undergo tens of thousands of pressing tests. Silicon conductive rubber buttons can withstand long-term and high-frequency use due to their high elasticity and good wear resistance, and their conductive performance does not significantly degrade. In addition, by adjusting the formula of the silicone rubber and the content of conductive fillers, different button touches can be customized, such as soft or crisp types, to meet the usage needs of different users.

(2) Connectors

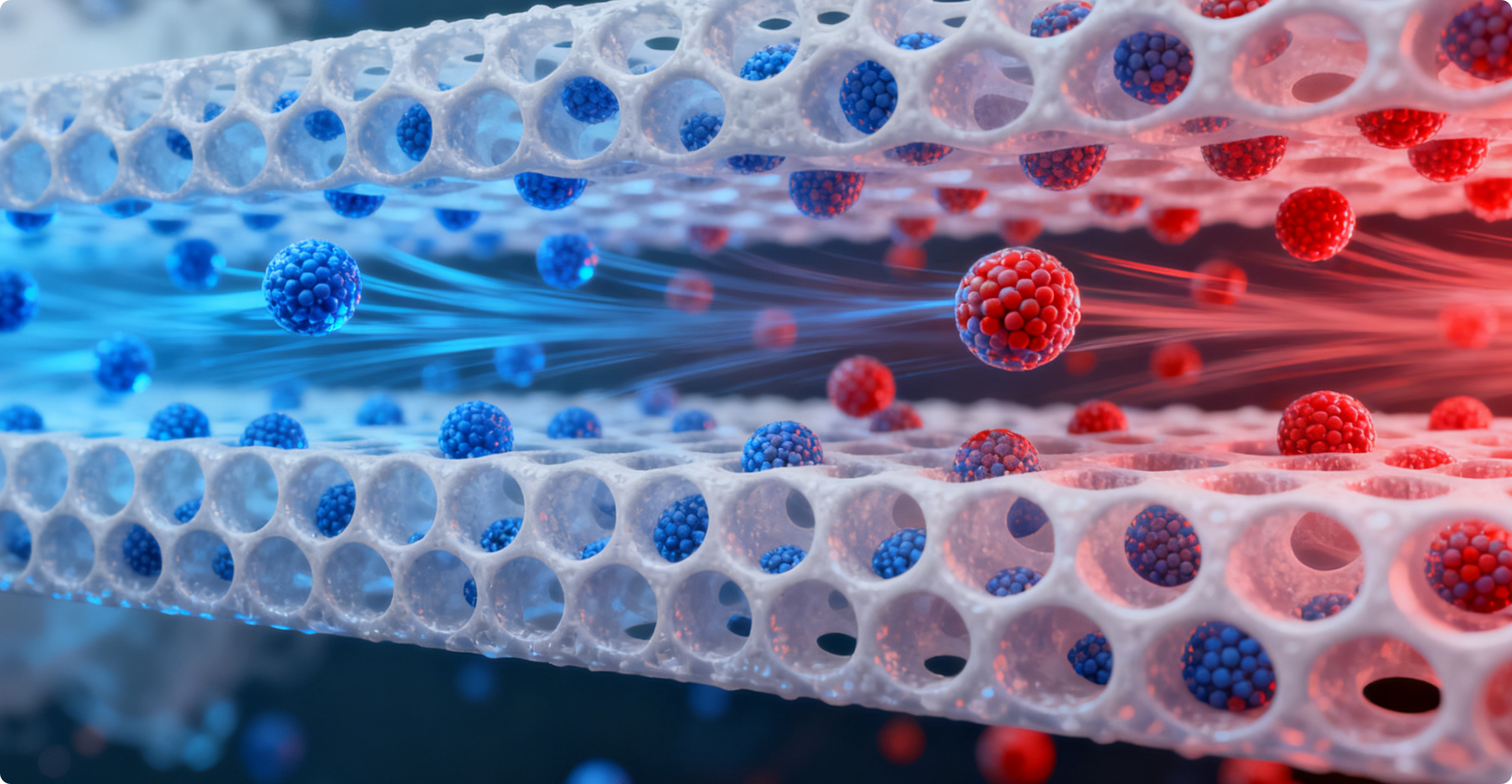

Inside communication equipment, the stable transmission of electrical signals between circuit boards and modules is crucial. Connectors and connection pads made of silicon conductive rubber can achieve reliable electrical connections and have certain buffering and shock absorption functions. Compared with traditional metal connectors, silicon conductive rubber connectors have good flexibility, can adapt to connection needs of different shapes and sizes, and effectively avoid poor contact caused by factors such as equipment vibration and thermal expansion and contraction.

In aviation communication equipment, due to the strong vibration and complex electromagnetic environment during flight, the performance requirements for connectors are extremely high. Silicon conductive rubber connectors closely fit the connection points of the circuit board, not only ensuring the stable transmission of electrical signals but also buffering vibration through their own elasticity to protect circuit components from damage. At the same time, the combination of its conductive performance and electromagnetic shielding performance can effectively reduce EMI during signal transmission, improving the reliability and stability of communication equipment.

III. Antenna Components

(1) Antenna Sealing

As a key component for communication equipment to receive and transmit signals, the performance of an antenna directly affects communication quality. Silicon conductive rubber is used for antenna sealing, which can not only prevent external environmental factors such as rainwater, dust, and salt spray from eroding the internal structure of the antenna but also play a certain electromagnetic shielding role. In outdoor communication base station antennas, silicon conductive rubber seals tightly wrap the connection parts and feeder interfaces of the antenna to form a solid protective barrier.

For example, in communication base stations in coastal areas, antennas face harsh environments of high humidity and high salt spray for a long time. Silicon conductive rubber can effectively resist the corrosion of salt spray and prevent the rusting of antenna metal parts due to its excellent weather resistance and chemical stability, thus ensuring the stable electrical performance of the antenna. Meanwhile, its electromagnetic shielding function can reduce the impact of external EMI on the antenna signal, improving the receiving sensitivity and transmission efficiency of the antenna.

(2) Antenna Connection

A reliable conductive connection between the antenna and the equipment main body is an important link to ensure efficient signal transmission. Silicon conductive rubber has good electrical conductivity and flexibility, enabling flexible connection between the antenna and the equipment and reducing connection failures caused by mechanical stress. In UAV communication antennas, traditional rigid connection methods are prone to loosening and breaking due to the 剧烈 (severe) vibration and attitude changes of the UAV during flight.

Using silicon conductive rubber to connect the antenna with the internal circuit of the fuselage can not only ensure the stable transmission of electrical signals but also buffer vibration and stress through its own elasticity to protect the antenna and circuit connection points from damage. In addition, the high and low-temperature resistance of silicon conductive rubber allows it to maintain good conductive performance and connection stability when the UAV passes through different temperature environments, ensuring smooth communication between the UAV and the ground control station.