What role does silicone potting adhesive play in inverters?

2025/08/20

0

In the context of the rapid development of the new energy industry, inverters, as core equipment for electrical energy conversion, their stable operation is directly related to the efficiency and safety of the entire energy system. Take a photovoltaic power station as an example: if a 30kW inverter shuts down due to a fault, it will cause a power generation loss of approximately 120 kWh per day. With its unique performance advantages, silicone potting adhesive has become a key material to ensure the long-term and reliable operation of inverters, and is widely used in the industry.

The reason why silicone potting adhesive can adapt to the working environment of inverters first lies in its excellent electrical insulation performance. Inverters contain a large number of precision electronic components, such as IGBT modules, capacitors, inductors, etc. These components operate under high-voltage and high-current conditions, which have extremely high requirements for insulation. For example, in wind power generation systems, inverters need to withstand AC voltages of 690V or even higher, and tiny insulation defects may cause serious accidents. The elastic colloid formed after the curing of silicone potting adhesive can effectively isolate the electrical connections between components, preventing faults such as leakage and short circuits. Its dielectric constant is usually stable between 2.8-3.2, and the dielectric loss tangent is less than 0.005, which can significantly reduce energy loss during transmission. Actual measurements show that it can improve the conversion efficiency of the inverter by 0.8%-1.2%.

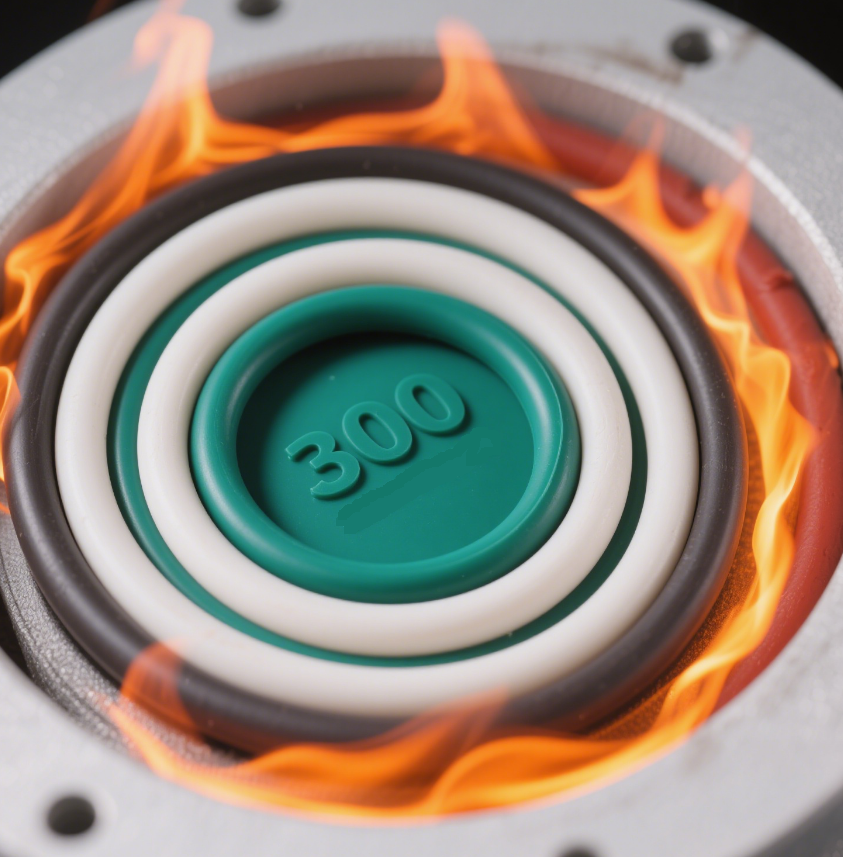

Secondly, inverters generate a lot of heat during operation, especially when outputting high power, the internal temperature may rise sharply. Take the vehicle-mounted inverter as an example: when continuously outputting 15kW of power, the surface temperature of the IGBT module can reach above 120℃. Silicone potting adhesive has excellent thermal conductivity, with a thermal conductivity of 1.5-3.0W/(m·K), which can quickly conduct the heat generated by components to the shell, and then dissipate it through the heat dissipation system. At the same time, it also has a wide temperature resistance range, and can maintain stable performance in a temperature environment from -50℃ to 200℃ or even higher. In extremely low-temperature environments, the colloid will not lose its protective effect due to embrittlement; in high-temperature environments, it will not soften or flow. Whether in the cold northern winter or in high-temperature outdoor cabinets, it can provide continuous protection for the inverter.

Inverters used outdoors also face the test of complex natural environments, such as humidity, rain, ultraviolet radiation, and acid-base corrosion. In coastal areas, inverters need to withstand the erosion of high salt spray and high humidity for a long time; in areas with serious industrial pollution, they may also face the threat of corrosive substances such as acid rain. The colloid formed after the curing of silicone potting adhesive has excellent weather resistance and sealing performance, which can tightly wrap the internal components to form a strong protective barrier. Its contact angle can reach more than 110°, which can effectively block the intrusion of moisture; after 5000 hours of UV aging test, the tensile strength retention rate of the colloid is still above 90%, which can effectively resist ultraviolet radiation. It will not crack or age even after long-term exposure to sunlight, greatly extending the service life of the inverter.

In addition, inverters will inevitably be subject to vibration and impact during transportation, installation, and operation. For example, in the application scenario of vehicle-mounted inverters, the 颠簸 vibration during vehicle driving may cause component loosening; inverters in photovoltaic power stations also face the risk of structural vibration in strong winds. Silicone potting adhesive has appropriate elasticity and toughness, and its Shore hardness is usually controlled between 20-60A, which can absorb external vibration energy and reduce mechanical stress on internal components. According to vibration test standards (such as GB/T 2423.10), after the frequency sweep vibration test of 10-500Hz, the intact rate of internal components of the potted inverter can reach more than 98%, which effectively prevents components from loosening or damage due to vibration, ensuring that the inverter can operate stably under various complex working conditions.

To sum up, relying on excellent electrical insulation, thermal conductivity, temperature resistance, weather resistance, and vibration resistance, silicone potting adhesive provides comprehensive protection for inverters. It is an important material to ensure the efficient, stable, and long-term operation of inverters, and plays an irreplaceable role in the new energy field.