Wave-absorbing Rubber in the Field of Unmanned Aerial Vehicles (UAVs)

2025/06/17

0

1. Introduction

Unmanned Aerial Vehicles (UAVs) have witnessed a remarkable surge in their applications across diverse fields in recent years. They are extensively utilized in areas such as aerial photography, agricultural monitoring, logistics delivery, and even military reconnaissance. However, with the increasing complexity of the electromagnetic environment, UAVs are constantly exposed to various electromagnetic interferences, which pose significant threats to their stable operation and stealth performance.

Wave – absorbing materials play a crucial role in addressing these challenges. Among them, wave – absorbing rubber has emerged as a promising candidate due to its unique properties. This article aims to comprehensively explore the application of wave – absorbing rubber in the field of UAVs, including its working principles, advantages, specific applications, and the latest research progress.

2. Working Principles of Wave – Absorbing Rubber

2.1 Dielectric Loss Mechanism

Wave – absorbing rubber often contains dielectric materials. When an electromagnetic wave impinges on the rubber, the electric field component of the wave causes the polarization of the dielectric medium within the rubber. This polarization process leads to energy dissipation in the form of heat due to the movement of polar molecules and the associated frictional forces. For example, materials like carbon black or certain metal oxides incorporated in the rubber matrix can enhance dielectric loss. These materials have polarizable groups or charge – carriers that interact with the electromagnetic wave’s electric field, converting the electromagnetic energy into thermal energy, thus reducing the intensity of the reflected wave.

2.2 Magnetic Loss Mechanism

Some wave – absorbing rubbers are designed to possess magnetic properties. Magnetic loss occurs when the magnetic field component of the electromagnetic wave interacts with the magnetic domains in the rubber. Ferromagnetic or ferrimagnetic fillers, such as iron – based powders (e.g., carbonyl iron powder) or ferrite materials, are commonly added to the rubber matrix. As the magnetic field of the incident wave changes, it causes the magnetization and demagnetization of these magnetic fillers. During this process, energy is dissipated in the form of hysteresis loss and eddy – current loss. Hysteresis loss results from the irreversible movement of magnetic domains, while eddy – current loss is generated due to the induced electric currents in the magnetic materials, both contributing to the absorption of electromagnetic waves.

2.3 Impedance Matching Principle

To effectively absorb electromagnetic waves, wave – absorbing rubber must meet the impedance matching condition. The impedance of the wave – absorbing material should be as close as possible to the impedance of the free space. When the impedance of the rubber is well – matched with that of the surrounding medium (air, in the case of UAVs in flight), the electromagnetic wave can enter the material with minimal reflection. This is achieved by carefully adjusting the composition and structure of the rubber, including the type and content of fillers, as well as the thickness of the rubber layer. For instance, by optimizing the ratio of dielectric and magnetic fillers in the rubber matrix, the overall impedance of the material can be tuned to approach the impedance of free space, ensuring efficient wave absorption.

3. Advantages of Wave – Absorbing Rubber for UAV Applications

3.1 Lightweight Feature

One of the significant advantages of wave – absorbing rubber is its lightweight nature. In the design of UAVs, weight is a critical factor as it directly affects the flight performance, energy consumption, and payload capacity. Compared to some traditional heavy – duty wave – absorbing materials, such as certain metal – based composites, wave – absorbing rubber offers a much lower density. This lightweight characteristic allows UAVs to maintain their agility and efficiency during flight while still benefiting from effective electromagnetic wave absorption. For example, in the construction of UAV fuselages or wings, using wave – absorbing rubber instead of heavier materials can reduce the overall weight of the aircraft, leading to longer flight times and increased maneuverability.

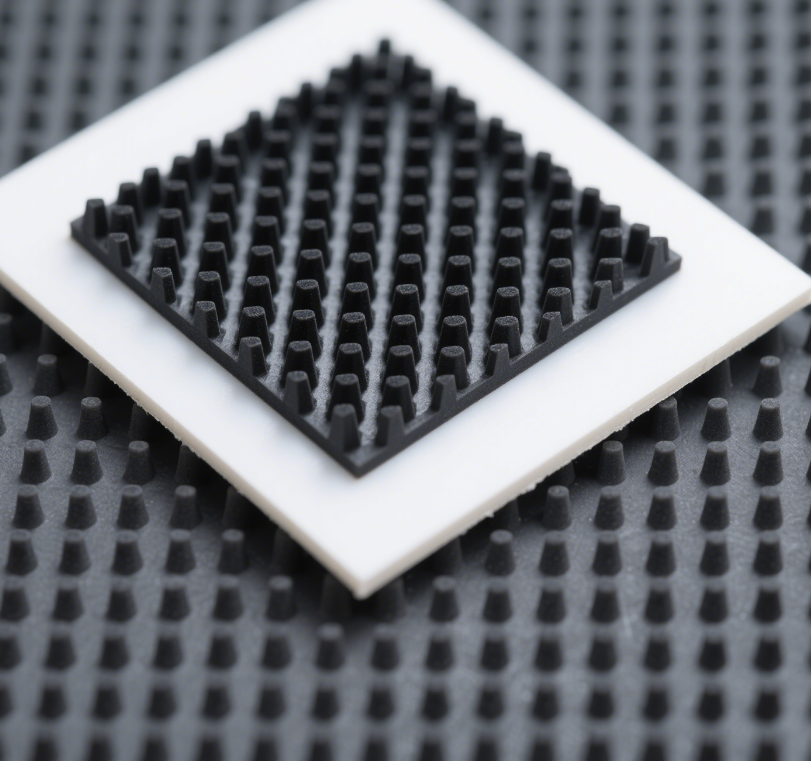

3.2 Flexibility and Mouldability

Wave – absorbing rubber exhibits excellent flexibility and mouldability, which is highly advantageous for UAV manufacturing. UAVs often have complex shapes and curved surfaces, and wave – absorbing rubber can be easily moulded into various forms to conform to these geometries. This flexibility enables seamless integration of the wave – absorbing material into different parts of the UAV, ensuring comprehensive protection against electromagnetic interference. For instance, it can be shaped to fit around antennae, sensors, or other critical components, providing targeted electromagnetic shielding. Moreover, the flexibility of the rubber also allows it to withstand the mechanical stresses and vibrations experienced during UAV flight without cracking or losing its wave – absorbing properties.

3.3 Durability and Environmental Resistance

UAVs operate in diverse and often harsh environmental conditions, including varying temperatures, humidity levels, and exposure to chemicals. Wave – absorbing rubber demonstrates good durability and environmental resistance under such circumstances. It can maintain its physical and electromagnetic properties over a wide temperature range, from extremely cold to hot environments. Additionally, rubber is naturally resistant to moisture, which helps prevent the degradation of its wave – absorbing performance due to water absorption. In the case of exposure to chemicals in industrial or agricultural monitoring applications, wave – absorbing rubber can withstand certain chemical attacks, ensuring long – term and reliable operation of the UAV in different environments.

4. Specific Applications of Wave – Absorbing Rubber in UAVs

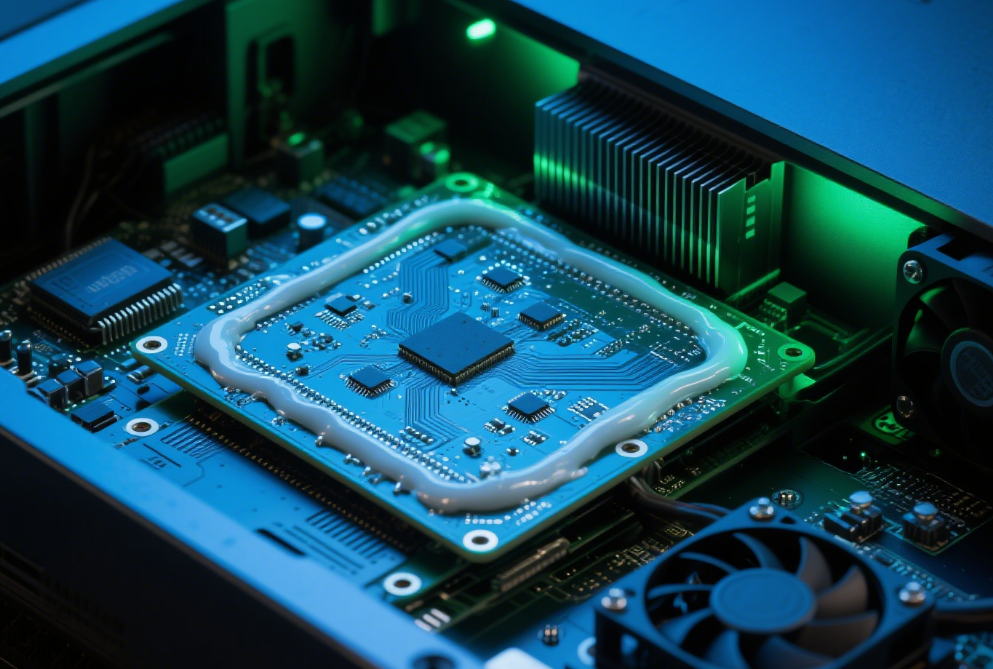

4.1 Electromagnetic Interference (EMI) Shielding for Avionics

The avionics systems in UAVs, which include flight control computers, communication modules, and navigation systems, are highly sensitive to electromagnetic interference. EMI can disrupt the normal operation of these systems, leading to flight instability, communication breakdowns, or inaccurate navigation. Wave – absorbing rubber is applied as a shielding material around avionics components to prevent external electromagnetic waves from interfering with their operation. For example, rubber gaskets with wave – absorbing properties can be used to seal the enclosures of avionics modules, effectively blocking out unwanted electromagnetic radiation. By reducing EMI, wave – absorbing rubber helps ensure the reliable and stable operation of UAV avionics, improving the overall flight safety and mission success rate.

4.2 Radar Cross – Section (RCS) Reduction for Stealth

In military and some special – purpose UAV applications, stealth is a crucial requirement. The Radar Cross – Section (RCS) of a UAV determines its detectability by radar systems. Wave – absorbing rubber can be used to reduce the RCS of UAVs. By covering the outer surfaces of the UAV, such as the fuselage, wings, and tail, with wave – absorbing rubber, the electromagnetic waves incident on the UAV are absorbed rather than reflected back to the radar. This significantly reduces the UAV’s radar signature, making it more difficult to detect. In addition to surface covering, wave – absorbing rubber can also be integrated into the design of UAV structures, such as the internal frames, to further enhance the overall stealth performance. The use of wave – absorbing rubber for RCS reduction enables UAVs to operate more covertly in areas where radar surveillance is present.

4.3 Vibration Damping and Noise Reduction

During flight, UAVs experience vibrations from the rotation of propellers, engine operation (if applicable), and air turbulence. These vibrations can not only affect the accuracy of sensors and imaging equipment on board but also generate noise. Wave – absorbing rubber, with its inherent damping properties, can be used to reduce vibrations and associated noise. For example, rubber mounts made of wave – absorbing rubber can be used to isolate sensitive components, such as cameras or LiDAR sensors, from the vibration sources. The rubber’s ability to dissipate mechanical energy helps to minimize the transfer of vibrations to these components, improving their performance and the quality of data collected. Additionally, the reduction in noise levels can be beneficial in applications where quiet operation is desired, such as wildlife monitoring or surveillance in noise – sensitive areas.

5. Research Progress in Wave – Absorbing Rubber for UAVs

5.1 Development of New Rubber Matrix Materials

Researchers are constantly exploring new rubber matrix materials with enhanced properties for wave – absorbing applications in UAVs. For example, the development of high – performance silicone rubber matrices has shown great potential. Silicone rubber offers excellent thermal stability, which is crucial for UAVs operating in high – temperature environments, such as those involved in long – range flights or missions in hot regions. Newly developed silicone rubber matrices can maintain their wave – absorbing performance even at elevated temperatures, ensuring the continuous protection of UAV components. Additionally, the synthesis of novel elastomers with improved mechanical strength and flexibility is being investigated. These new matrix materials can better withstand the mechanical stresses during UAV flight and also provide a more stable base for the incorporation of wave – absorbing fillers.

5.2 Optimization of Absorbent Fillers

The selection and optimization of absorbent fillers in wave – absorbing rubber are also areas of active research. Nanocomposite fillers are being increasingly studied. For instance, carbon – based nanomaterials like carbon nanotubes and graphene nanoplatelets are being explored for their high surface – to – volume ratio and excellent electrical conductivity. When incorporated into rubber matrices, these nanocomposites can enhance the dielectric loss and impedance matching characteristics of the wave – absorbing rubber. In addition, the development of hybrid fillers that combine magnetic and dielectric materials at the nanoscale is a promising approach. These hybrid fillers can potentially offer improved wave – absorbing performance over a broader frequency range. By precisely controlling the size, shape, and distribution of these nanocomposite and hybrid fillers in the rubber matrix, researchers aim to develop wave – absorbing rubbers with superior performance for UAV applications.

5.3 Multifunctional Wave – Absorbing Rubber

There is a growing trend towards developing multifunctional wave – absorbing rubber for UAVs. Such rubber is designed to not only absorb electromagnetic waves but also possess other beneficial properties. For example, self – healing wave – absorbing rubber is being developed. In the event of minor damage to the UAV’s wave – absorbing rubber coating during flight, the self – healing property allows the rubber to repair itself, maintaining its electromagnetic shielding and other functions. Another area of research is the development of wave – absorbing rubber with anti – icing or anti – fouling properties. In cold or humid environments, UAVs are prone to icing on their surfaces, which can affect flight performance. Wave – absorbing rubber with anti – icing properties can prevent ice formation, while anti – fouling properties can keep the UAV’s surfaces clean, reducing the drag and improving the overall efficiency of the aircraft.

6. Challenges and Future Perspectives

6.1 Challenges in Material Performance and Cost

Despite the progress made, there are still challenges in the material performance of wave – absorbing rubber for UAVs. One of the main challenges is achieving a balance between high – performance wave absorption and other properties such as mechanical strength and weight. Some high – performance wave – absorbing fillers may increase the weight of the rubber or compromise its mechanical integrity. Additionally, the cost of manufacturing wave – absorbing rubber with advanced materials and complex structures can be relatively high, which may limit its widespread application in the UAV industry, especially for cost – sensitive consumer and commercial UAVs. Developing cost – effective manufacturing processes and finding alternative, more affordable materials without sacrificing performance is a key challenge that needs to be addressed.

6.2 Integration and Compatibility Issues

Integrating wave – absorbing rubber into UAV structures and ensuring its compatibility with other components pose significant challenges. UAVs are complex systems with multiple subsystems and components that interact with each other. The wave – absorbing rubber needs to be seamlessly integrated into the overall design without interfering with the functionality of other parts, such as aerodynamics, power systems, or communication antennas. Moreover, ensuring the long – term compatibility of wave – absorbing rubber with different materials used in UAV construction, including metals, composites, and plastics, is crucial. Any chemical or physical incompatibility could lead to degradation of the wave – absorbing performance or structural integrity of the UAV over time.

6.3 Future Perspectives

Looking ahead, the future of wave – absorbing rubber in UAVs is promising. With the continuous development of 5G and future communication technologies, the electromagnetic environment will become even more complex, further increasing the demand for effective wave – absorbing materials in UAVs. Advancements in nanotechnology and materials science are expected to lead to the development of more efficient and lightweight wave – absorbing rubbers. For example, the use of artificial intelligence and machine learning algorithms may help in the design and optimization of wave – absorbing rubber structures, enabling the creation of materials with tailored electromagnetic properties. Additionally, as the UAV market continues to expand, especially in areas such as urban air mobility and delivery services, the need for reliable and cost – effective wave – absorbing solutions will drive further research and innovation in this field.

7. Conclusion

Wave – absorbing rubber has shown great potential in enhancing the performance and functionality of UAVs in the face of electromagnetic challenges. Its unique working principles, combined with advantages such as lightweight, flexibility, and durability, make it an ideal material for various applications in UAVs, including EMI shielding, RCS reduction, and vibration damping. The continuous research progress in developing new rubber matrix materials, optimizing absorbent fillers, and creating multifunctional wave – absorbing rubbers bodes well for the future of UAV technology. However, challenges related to material performance, cost, integration, and compatibility need to be overcome. By addressing these challenges, wave – absorbing rubber is expected to play an increasingly important role in enabling the safe, reliable, and stealthy operation of UAVs in a wide range of applications.