Waterproofing Solutions for Electronics, Batteries and Other Products

2025/08/14

0

Coating with waterproof adhesive is a fundamental process in the waterproof protection system for electronic circuit boards. It achieves physical block water vapor, particulate contaminants, and chemical media by constructing a continuous and dense polymer protective film on the surface of the circuit board. Based on differences in the main polymer components, the current mainstream waterproof adhesive products can be divided into three major systems: acrylate, silicone, and polyurethane.

Waterproofing Solutions for Electronics, Batteries and Other Products

Acrylate-based waterproof adhesives are widely used in the field of consumer electronic products due to their excellent interface adhesion performance and good outdoor weather resistance, and they also have significant cost advantages. Silicone-based waterproof adhesives, with their excellent high and low-temperature stability (-60℃ to 200℃) and elastic deformation recovery ability, have become the first choice for high-reliability scenarios such as aerospace and industrial control. Polyurethane-based waterproof adhesives excel in chemical corrosion protection and mechanical wear resistance, making them suitable for harsh environments such as petrochemical industry.

This protective process features standardized operating procedures and simple equipment requirements, and is particularly suitable for civil electronic products with protection level requirements in the IPX4 – IPX6 range. However, it should be noted that its protective efficiency has limitations and cannot meet the protection needs of long-term immersion or high-pressure dynamic water environments. In the actual coating process, it is necessary to strictly control the coating thickness (0.1 – 0.3mm is recommended), curing process parameters, and adopt technical means such as vacuum defoaming and automatic spraying to ensure the uniformity of the coating and avoid the risk of protection failure caused by defects such as bubbles and missing coating.

Using Waterproof Enclosures

The use of waterproof enclosures is an important technical measure in the protection system of electronic circuit boards. This protection scheme effectively blocks the intrusion of the external humid environment into the circuit board through physical isolation, thereby achieving the waterproof protection function.

In terms of enclosure material selection, different materials have different performance characteristics: engineering plastic enclosures, with their lightweight properties and cost advantages, perform well in scenarios sensitive to weight and with relatively stable application environments, such as smart home control systems. Metal enclosures, with their excellent mechanical strength, thermal conductivity, and outstanding waterproof sealing performance, are widely used in fields with high protection level requirements such as industrial automation equipment and outdoor monitoring instruments.

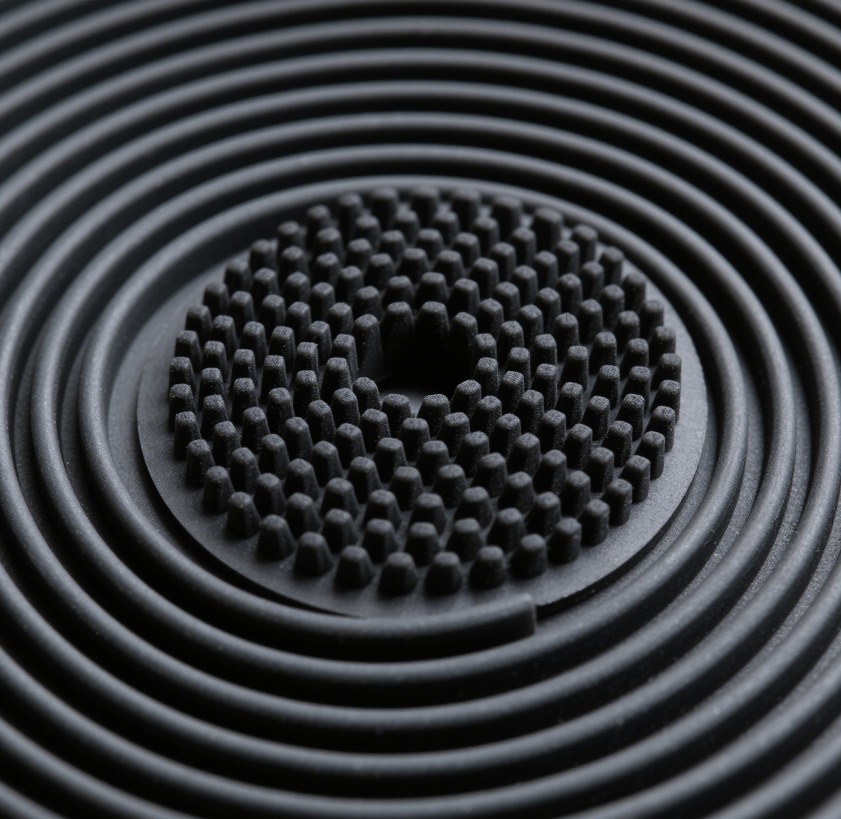

In the design and selection stage of waterproof enclosures, it is necessary to systematically consider the application environment parameters throughout the entire life cycle of the equipment, including temperature gradient changes, humidity fluctuation ranges, mechanical vibration intensity, and the risk of contact with potential corrosive media. During the installation process, the reliability of the sealing system directly affects the protection efficiency. It is recommended to select sealing elements such as rubber sealing rings that precisely match the enclosure structure, and strictly follow the tolerance matching standards to ensure that the sealing interface meets the expected protection level requirements.

Titanate coupling agents and high-performance sealants, with their excellent interface affinity and sealing performance, are often used as alternative protection schemes to sealing rings in the waterproof process of electronic circuit boards.

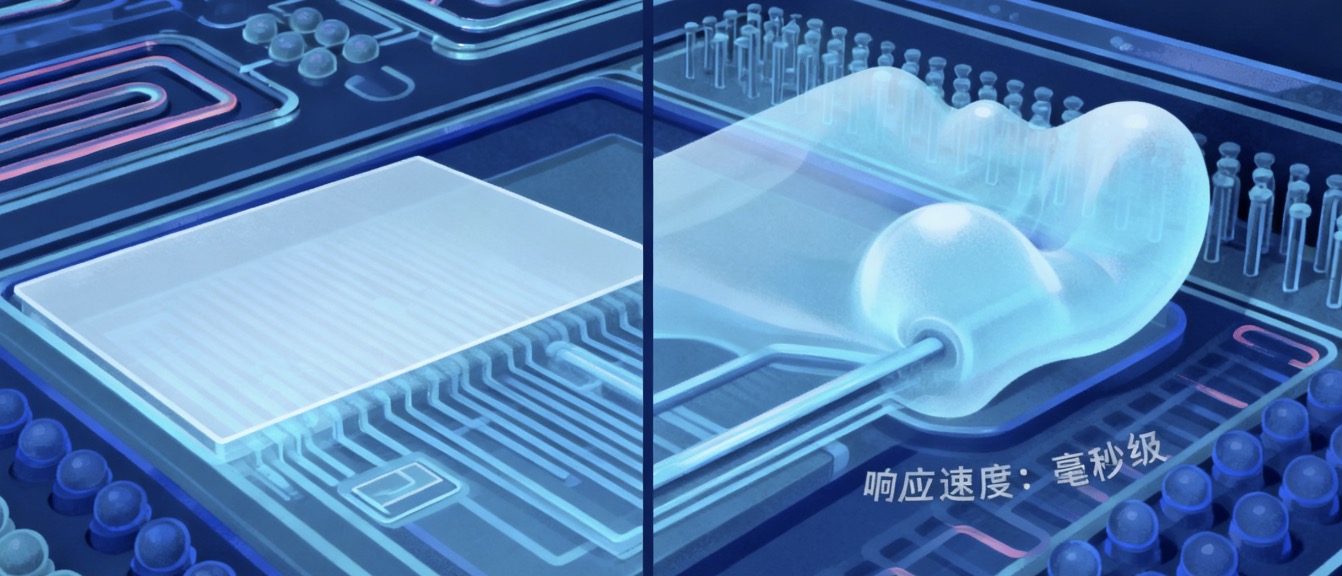

Potting Treatment

Potting treatment involves completely wrapping the electronic circuit board in potting material to form a sealed whole, thereby achieving complete waterproof, moisture-proof, dust-proof, and shock-proof effects.

Silicone potting materials with adhesiveness have medium hardness, strong adhesion, and good insulation performance, making them suitable for occasions with high requirements for mechanical strength.

This method has excellent waterproof effects and can adapt to various harsh environments, such as underwater equipment and automotive electronics. However, after potting treatment, the maintenance of the circuit board is more difficult. Once internal components fail, it is often necessary to destroy the potting material for maintenance. Moreover, the cost of potting materials is relatively high, and the potting process is more complex, requiring strict control of parameters such as temperature and pressure during the potting process to ensure the potting quality.

Auxiliary Waterproof Measures

Considering waterproof layout when designing the circuit board is also an important auxiliary waterproof measure. For example, try to arrange components in positions that are not prone to water accumulation, avoid placing important components on the edges or corners of the circuit board; design wiring reasonably to reduce the length of the circuit exposed to areas prone to water ingress; set drainage holes on the circuit board to facilitate the discharge of a small amount of water vapor that enters.

Maintenance

Regular inspection and maintenance of the waterproof condition of electronic circuit boards can timely detect waterproof failure and ensure the durability of the waterproof effect. For example, check whether the waterproof adhesive layer is cracked or peeled off; check whether the sealing ring of the waterproof enclosure is aged or deformed, and whether the enclosure is damaged; for potted circuit boards, observe whether the potting material has bubbles, cracks, etc. Once problems are found, corresponding repair measures should be taken in a timely manner, such as re-coating with waterproof adhesive, replacing the sealing ring, and repairing the potting material.