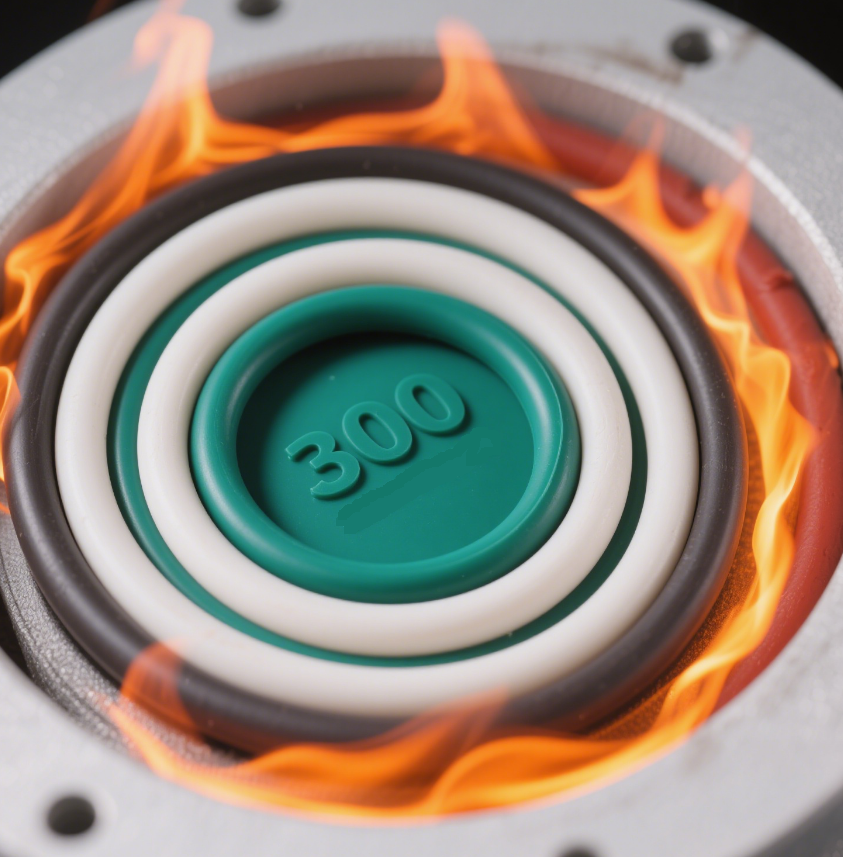

Transparent silicone that can withstand 300 degrees Celsius

The transparent silicone rubber resistant to 300 degrees Celsius is a high-performance special material. It combines the flexibility, chemical stability and high light transmittance of silicone rubber materials, and at the same time has excellent high-temperature resistance performance. It can be used for a long time in a high-temperature environment of 300℃ without obvious performance degradation, discoloration or decomposition. This characteristic has enabled it to be widely and crucially applied in multiple fields.

In the field of industrial manufacturing, transparent high-temperature-resistant silicone rubber is often used as a sealing and protective material in high-temperature environments. In the manufacturing of sealing gaskets for automotive engines, it can withstand the high temperatures generated during engine operation, prevent the leakage of engine oil and coolant, and ensure the normal operation of the engine. In the sealing process of chemical reaction kettles, it can resist the erosion of high-temperature corrosive gases and liquids, maintain the tightness of the reaction kettle, and prevent the leakage of hazardous chemicals. In addition, in high-temperature processing industries such as glass manufacturing and ceramic firing, transparent high-temperature-resistant silicone rubber can also be used to make high-temperature-resistant molds and fixtures. Due to its transparent characteristic, it is convenient to observe the changes of materials during the processing, thereby improving production efficiency and product quality.

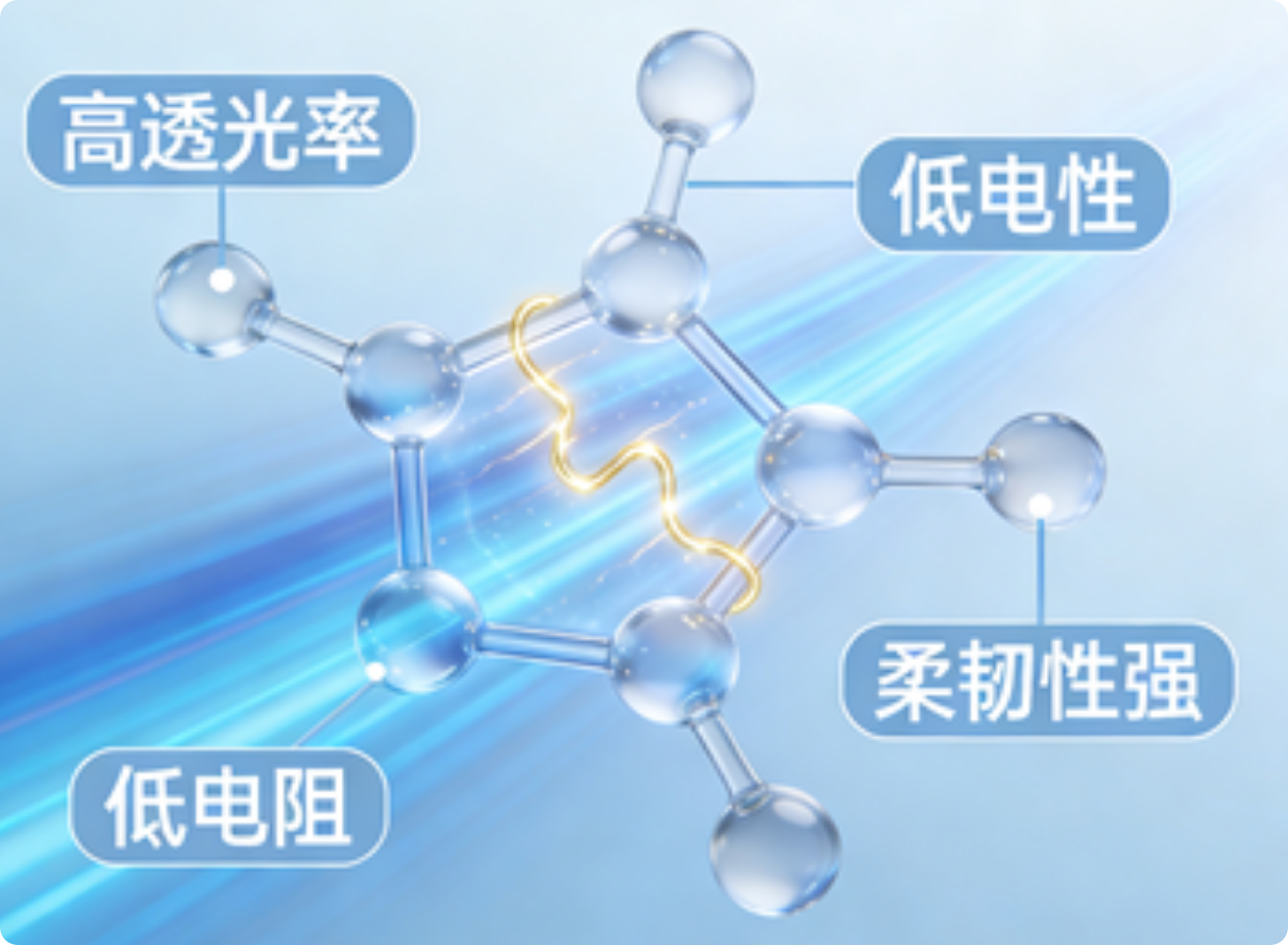

The electronics and electrical appliance industry also has a strong demand for transparent silicone rubber resistant to 300 degrees Celsius. In the field of LED lighting, it is used for encapsulating LED chips. It can not only protect the chips from the influence of the external environment, but also ensure the high light transmittance of the light, improving the luminous efficiency and service life of LED lights. For electronic devices operating in high-temperature environments, such as the circuit protection inside ovens and microwave ovens, transparent high-temperature-resistant silicone rubber can be used to pot the circuit boards and electronic components, preventing damage to the components caused by high temperatures, moisture and dust, and enhancing the stability and reliability of the devices.

In the medical field, transparent high-temperature-resistant silicone rubber has unique applications due to its non-toxic, harmless and good biocompatibility characteristics. It can be used to manufacture components of medical devices for high-temperature disinfection, such as sealing parts of surgical instruments and protective sleeves of medical endoscopes. These components require materials with good high-temperature resistance performance during the high-temperature and high-pressure disinfection process, and the transparent characteristic is convenient for observing and inspecting the internal conditions of the instruments. In addition, in dental restoration materials, transparent high-temperature-resistant silicone rubber can also be used to make temporary crowns, dental molds, etc., providing patients with a comfortable and safe treatment experience.

In daily life, transparent silicone rubber resistant to 300 degrees Celsius also plays a role. In terms of kitchen utensils, it can be used to make transparent high-temperature-resistant baking trays, placemats, etc. These products are not only resistant to high temperatures, but also easy to clean and have high safety. In the production of handicrafts, transparent high-temperature-resistant silicone rubber can be used to make molds for casting materials such as resin and wax, which can clearly show the details of the handicrafts and improve the production precision and aesthetic appeal of the handicrafts.

With the continuous development of science and technology, the application fields of transparent silicone rubber resistant to 300 degrees Celsius are still expanding. In the future, it is expected to play a greater role in high-tech fields such as aerospace and new energy, providing strong support for the development of various industries.