Thermal conductive pad in navigation systems

2025/06/18

0

Introduction

In the contemporary world, navigation systems have become an indispensable part of various fields, including automotive, aerospace, and marine. These systems are tasked with providing accurate location, direction, and guidance information. However, the continuous miniaturization and increased functionality of navigation devices have led to a significant challenge – heat management. Excessive heat can degrade the performance and reliability of navigation system components. This is where thermal conductive pads come into play. Thermal conductive pads are a type of thermal interface material (TIM) that play a crucial role in ensuring the efficient dissipation of heat generated by navigation system components, thereby maintaining optimal operating conditions.

Working Principle of Thermal Conductive Pads in Navigation Systems

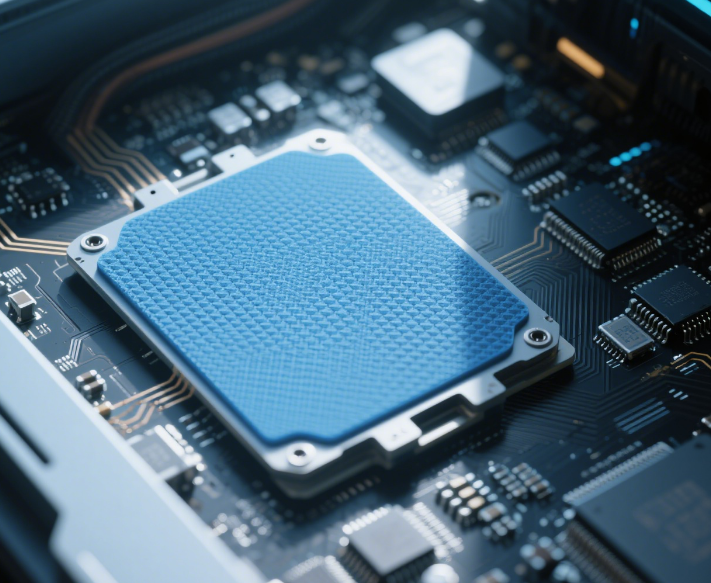

Navigation systems consist of multiple components such as processors, integrated circuits, and sensors, all of which generate heat during operation. Thermal conductive pads are placed between these heat – generating components and a heat sink or the device’s enclosure. Their primary function is to bridge the gap between the two surfaces, replacing the air – filled voids. Air has a very low thermal conductivity (about 0.026 W/m·K), which acts as a significant thermal barrier. In contrast, thermal conductive pads are made of materials with much higher thermal conductivities.

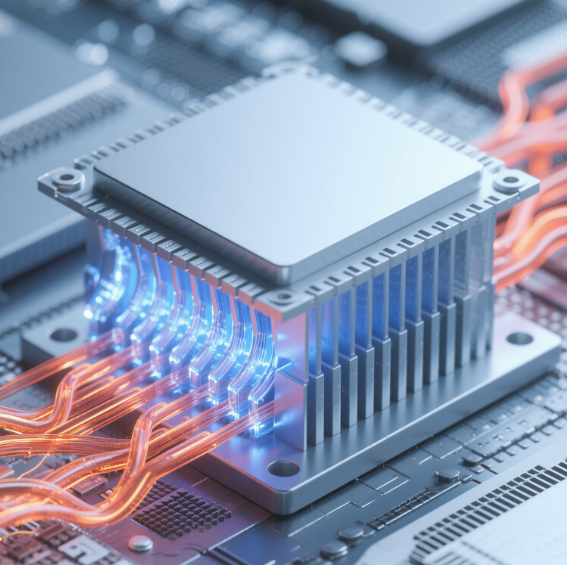

When heat is generated by a component in the navigation system, it first conducts into the thermal conductive pad. The pad, due to its high thermal conductivity, quickly transfers this heat to the heat sink or enclosure. The heat is then dissipated into the surrounding environment, either through natural convection or forced air cooling in some cases. This process helps to keep the temperature of the heat – generating components within an acceptable range, preventing overheating and its associated negative impacts on performance and lifespan.

Types of Thermal Conductive Pads Used in Navigation Systems

Silicone – Based Thermal Conductive Pads

Silicone – based thermal conductive pads are one of the most commonly used types in navigation systems. They are composed of a silicone matrix filled with thermally conductive fillers such as ceramic powders (e.g., aluminum oxide, boron nitride). These pads offer several advantages. Firstly, they are highly flexible and compliant. Navigation system components often have irregular surfaces, and the soft and conformable nature of silicone – based pads allows them to closely follow these surfaces, ensuring maximum contact area for efficient heat transfer. Secondly, they provide good electrical insulation. In navigation systems, where sensitive electronic components are present, electrical insulation is crucial to prevent short – circuits and interference. For example, in an automotive navigation system’s motherboard, silicone – based thermal pads can effectively transfer heat from the processor while protecting other nearby components from electrical issues. However, silicone pads may have some limitations, such as potential outgassing in certain high – temperature or high – humidity environments, which could potentially affect the performance of nearby components over time.

Graphite Thermal Conductive Pads

Graphite thermal conductive pads are another option for navigation systems. Graphite has excellent thermal conductivity, with values that can be several times higher than those of silicone – based pads in some directions. These pads are lightweight and can be customized to fit specific thermal management requirements in navigation devices. In aerospace navigation systems, where weight is a critical factor, graphite pads are often preferred. They can efficiently transfer heat from high – power components like satellite navigation receivers to the spacecraft’s heat – dissipating structure. Graphite pads also have good chemical stability, making them suitable for use in harsh environments. However, they may be more expensive to produce compared to silicone – based pads, and their mechanical properties may require careful consideration in some applications to ensure proper adhesion and durability.

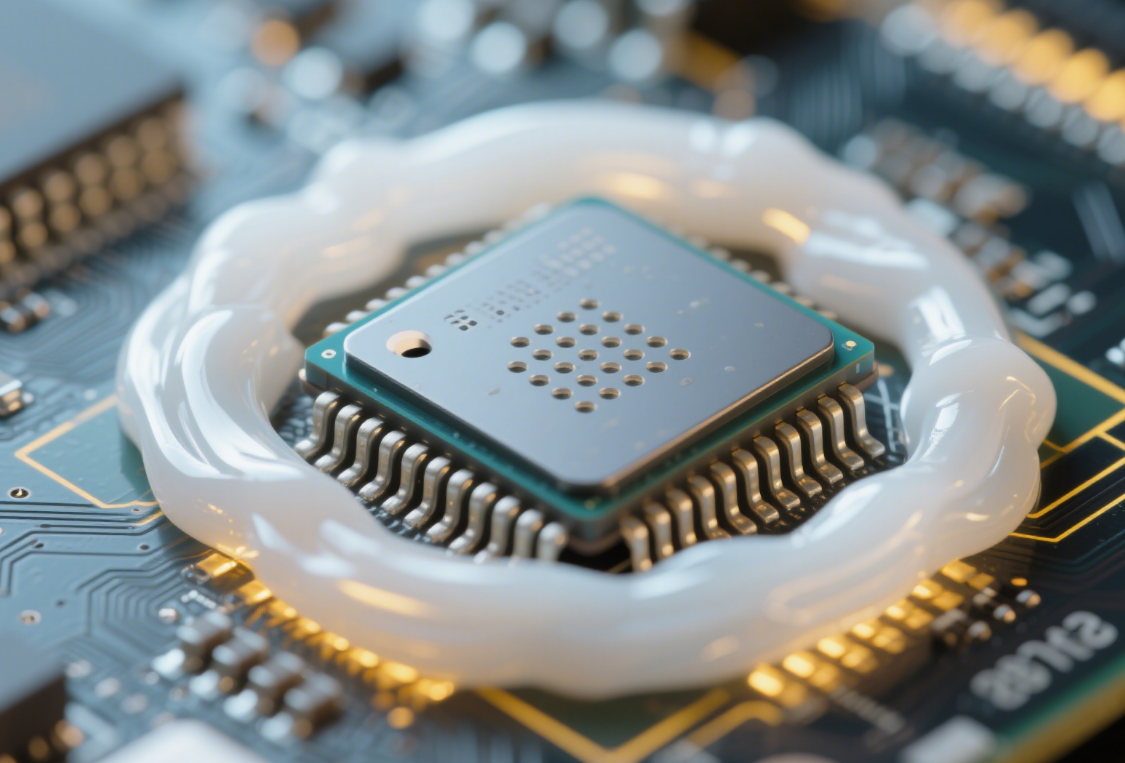

Phase Change Material (PCM) Thermal Conductive Pads

Phase change material thermal conductive pads are designed to change their physical state from solid to liquid within a specific temperature range. As the temperature of the navigation system components rises, the PCM in the pad starts to melt. During this phase transition, the PCM absorbs a significant amount of heat energy, known as the latent heat of fusion. This process helps to regulate the temperature of the components more effectively than traditional thermal pads. For instance, in a marine navigation system that experiences fluctuating temperatures due to changes in ambient conditions and the system’s own usage patterns, PCM thermal pads can maintain a more stable temperature for the system’s electronics. Once the temperature drops, the PCM solidifies again, releasing the stored heat. PCM pads are particularly useful in applications where there are short – term high – heat loads, as they can absorb the excess heat during these peak periods and then gradually release it when the load subsides.

Importance of Thermal Conductive Pads in Navigation System Performance

Ensuring Accurate Signal Processing

Navigation systems rely on precise signal processing to determine location, speed, and direction accurately. Heat can cause electronic components, such as processors and signal amplifiers, to experience thermal drift. This drift can lead to errors in signal processing, resulting in inaccurate navigation data. Thermal conductive pads help to keep these components cool, minimizing thermal drift and ensuring that the navigation system can process signals accurately. For example, in a global positioning system (GPS) receiver, which is a core component of many navigation systems, overheating can cause the receiver to misinterpret satellite signals, leading to incorrect position calculations. By using thermal conductive pads to dissipate heat, the GPS receiver can maintain stable operation and provide accurate location information.

Prolonging Component Lifespan

Excessive heat is one of the main factors that can shorten the lifespan of electronic components in navigation systems. High temperatures can accelerate the degradation of materials within components, such as the breakdown of semiconductor materials in integrated circuits. Thermal conductive pads help to lower the operating temperature of these components, reducing the stress on the materials and thus extending their lifespan. In an automotive navigation system that is constantly in use during long drives, the components are exposed to continuous heat generation. By effectively managing this heat with thermal conductive pads, the system’s components can last longer, reducing the need for frequent replacements and maintenance.

Improving System Reliability

A reliable navigation system is essential, especially in applications such as aviation and marine navigation, where safety is of utmost importance. Thermal conductive pads contribute to system reliability by preventing overheating – related failures. In an aircraft’s navigation system, any malfunction can have serious consequences. By using thermal conductive pads to ensure that components such as flight computers and navigation sensors operate within their optimal temperature range, the overall reliability of the navigation system is enhanced. This, in turn, increases the safety of the aircraft and its passengers.

Application Examples of Thermal Conductive Pads in Different Navigation Systems

Automotive Navigation Systems

In modern cars, navigation systems are integrated into the infotainment systems. These systems are used for route guidance, traffic information, and vehicle – to – everything (V2X) communication. The processors and communication modules in automotive navigation systems generate a significant amount of heat during operation. Thermal conductive pads are used to transfer this heat to heat sinks, which are often part of the vehicle’s chassis or dashboard structure. For example, a silicone – based thermal conductive pad may be placed between the navigation system’s central processing unit (CPU) and the heat sink. The pad fills the gaps between the uneven surfaces of the CPU and the heat sink, ensuring efficient heat transfer. This helps to keep the navigation system running smoothly, even during long drives in hot weather conditions when the ambient temperature and the heat generated by the vehicle’s engine can further increase the temperature inside the car.

Aerospace Navigation Systems

Aerospace navigation systems, including those used in aircraft and satellites, face extreme environmental conditions, including wide temperature variations. Thermal management is critical in these systems to ensure reliable operation. In satellites, thermal conductive pads are used to transfer heat from onboard navigation instruments, such as star trackers and inertial navigation systems, to the satellite’s thermal control system. Graphite thermal conductive pads are often favored in this application due to their high thermal conductivity and low weight. They can effectively dissipate heat in the harsh space environment, where heat dissipation via convection is not possible, and radiation is the primary mode of heat transfer. In aircraft, thermal conductive pads are used in flight computers and avionics systems to maintain optimal temperatures for accurate navigation and communication.

Marine Navigation Systems

Marine navigation systems, such as those used in ships and boats, need to operate reliably in a humid and often corrosive environment. Thermal conductive pads play a vital role in managing the heat generated by components like radar systems, GPS receivers, and autopilot controllers. Phase change material thermal conductive pads can be particularly effective in marine applications. They can absorb the heat generated during periods of high system usage, such as when a ship is navigating through a busy port or in adverse weather conditions. The ability of PCM pads to regulate temperature helps to prevent overheating of components, which could be more prone to failure in the humid marine environment. Additionally, the electrical insulation properties of thermal conductive pads protect the components from potential short – circuits caused by moisture.

Selection Criteria for Thermal Conductive Pads in Navigation Systems

Thermal Conductivity

The thermal conductivity of a thermal conductive pad is a crucial parameter. It determines how effectively the pad can transfer heat. In navigation systems, where efficient heat dissipation is essential, pads with high thermal conductivity are preferred. For high – power components in aerospace navigation systems, graphite pads with high thermal conductivity values may be selected. However, it’s important to note that the actual heat transfer performance also depends on other factors such as the thickness of the pad and the contact pressure between the pad and the components.

Compressibility and Conformability

Navigation system components often have irregular surfaces, and there may be small gaps between them and the heat sink. A good thermal conductive pad should be highly compressible and conformable to fill these gaps effectively. Silicone – based pads are known for their excellent compressibility and ability to conform to uneven surfaces, making them suitable for many navigation system applications. The compressibility of the pad ensures that it can adapt to the dynamic changes in the system, such as those caused by vibrations in automotive or aerospace applications.

Electrical Insulation

Since navigation systems are made up of sensitive electronic components, electrical insulation is a must. Thermal conductive pads should have high electrical resistance to prevent short – circuits. All types of thermal conductive pads used in navigation systems, whether silicone – based, graphite, or PCM – based, are designed to provide a certain level of electrical insulation. However, the degree of insulation may vary, and it’s important to select a pad with an appropriate insulation level for the specific navigation system application.

Chemical Stability

In different operating environments, such as the humid marine environment or the high – temperature and high – radiation space environment, the thermal conductive pad needs to be chemically stable. It should not react with the surrounding materials or degrade over time due to environmental factors. Graphite pads, for example, have good chemical stability, making them suitable for harsh aerospace and some marine applications. Chemical stability ensures the long – term reliability of the thermal management solution in the navigation system.

Conclusion

Thermal conductive pads are an essential component in modern navigation systems. They play a critical role in managing the heat generated by various components, which is crucial for ensuring accurate signal processing, prolonging component lifespan, and improving overall system reliability. With the continuous development of navigation technology, the demand for more efficient thermal management solutions will only increase. Different types of thermal conductive pads, such as silicone – based, graphite, and phase change material pads, offer unique properties that make them suitable for different navigation system applications. By carefully considering the selection criteria, including thermal conductivity, compressibility, electrical insulation, and chemical stability, system designers can choose the most appropriate thermal conductive pad to meet the specific requirements of their navigation systems. As technology advances, further improvements in thermal conductive pad materials and designs are expected, which will continue to enhance the performance and reliability of navigation systems in the future.