Thermal conductive pad in Medical Equipment

2025/06/16

0

Efficient Heat Dissipation: Many electronic components in medical devices generate a large amount of heat during operation. Thermal conductive pads can quickly conduct this heat away, preventing performance degradation, malfunctions, or even damage to the devices due to overheating, and ensuring stable operation of the equipment.

Improving Equipment Reliability: By effectively controlling temperature, thermal conductive pads help extend the service life of electronic components, reduce the frequency of equipment maintenance and replacement, enhance the reliability and availability of medical devices, and ensure the smooth progress of medical work.

Ensuring Precision and Accuracy: For temperature-sensitive medical devices such as diagnostic imaging equipment, thermal conductive pads can maintain the device within a stable operating temperature range, thereby ensuring the precision and accuracy of the equipment and providing doctors with accurate diagnostic basis.

Enhancing Safety: Preventing equipment overheating can reduce safety risks such as fires, and also avoid accidents like burns to patients caused by contact with overheated components during the use of medical devices, protecting the safety of patients and medical staff.

Applications of Thermal Conductive Pads in Different Medical Devices

Diagnostic Imaging Equipment

- MRI Machines: Used to conduct heat generated by electronic components such as power supplies, RF amplifiers, and control systems, maintaining stable operating temperature and ensuring the accuracy of imaging results.

- CT Scanners: Helps dissipate heat generated by components such as X-ray tubes and detectors, ensuring high-precision operation of the equipment to obtain clear tomographic images.

Patient Monitoring Systems

- Patient Monitors: Can dissipate heat generated by displays, processors, and communication modules, maintaining continuous monitoring and accurate patient data collection.

- Sleep Monitoring Devices: Can promptly conduct heat generated during equipment operation, ensuring long-term stable operation of the device and providing reliable data for sleep monitoring.

Surgical Equipment

- Electrosurgical Instruments: During surgery, it can effectively manage heat generated by electrosurgical instruments, maintain a safe working temperature, prevent overheating of key components, and ensure the safety and effectiveness of surgery.

- Laser Surgical Systems: In laser-based surgical equipment, it helps dissipate heat generated by laser sources and electronic control units, ensuring precise and reliable surgical operations and reducing thermal damage to surrounding tissues.

Medical Lasers

- Dermatological Laser Equipment: Used to manage heat generated by laser diodes and cooling systems, helping maintain stable energy output and protect sensitive skin tissues.

- Ophthalmic Laser Equipment: In ophthalmic laser surgery, it helps manage heat, ensuring accurate and controllable transmission of laser energy, and guaranteeing the safety and precision of eye surgery.

Implantable Devices

- Cardiac Devices: In implantable cardiac devices such as pacemakers and defibrillators, it is used to manage heat generated by electronic components, helping maintain the lifespan of components and reliable operation in the body.

- Nerve Stimulators: Used for heat dissipation in nerve stimulation devices, ensuring stable performance during pain management and treatment of nervous system diseases, and improving patient comfort.

Laboratory Equipment

- Analytical Instruments: In laboratory equipment such as spectrometers, chromatographs, and analyzers, it is used to manage heat generated by electronic modules and optical components, helping maintain the accuracy and reliability of instruments during analysis and testing.

Life Support Systems

- Ventilators and Respiratory Equipment: Used to manage heat generated by electronic components in ventilators and respiratory equipment, ensuring reliable operation of the equipment, precise control of air flow and pressure, and providing guarantee for patient respiratory support.

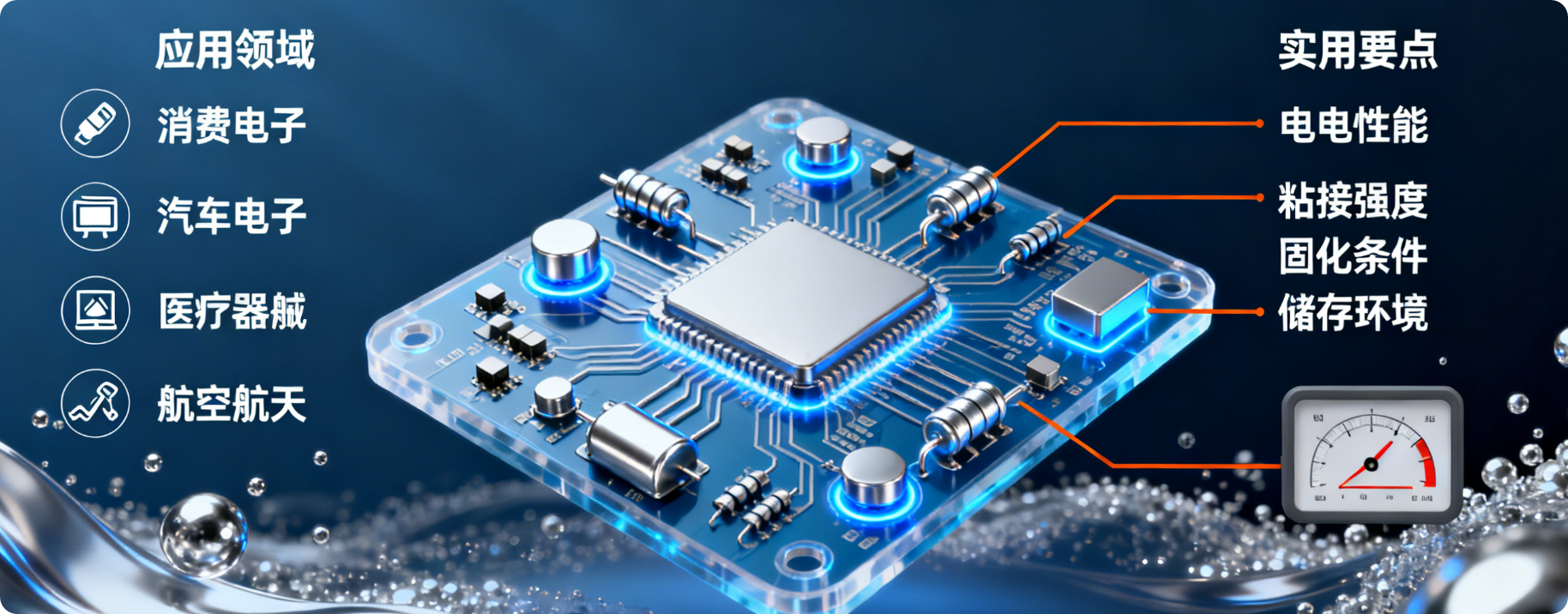

Selection Criteria for Thermal Conductive Pads in Medical Devices

- Thermal Conductivity: Thermal conductivity is an important indicator for measuring the performance of thermal conductive pads. Pads with high thermal conductivity should be selected to ensure efficient heat transfer.

- Biocompatibility: It must have good biocompatibility, will not cause adverse reactions to human tissues and body fluids, and comply with relevant biological safety standards.

- Electrical Insulation Performance: To prevent equipment short circuits or electric leakage, thermal conductive pads need to have good electrical insulation performance to ensure the electrical safety of equipment and patients.

- Flexibility and Compressibility: The internal space of medical devices is limited and the structure is complex. Thermal conductive pads should have good flexibility and compressibility, be able to closely fit the surfaces of heat-generating components and heat-dissipating parts, fill small gaps, and reduce thermal resistance.

- Compatibility and Stability: It should be compatible with other materials of medical devices, remain stable in the use environment and sterilization process of the device, and not have problems such as deformation, deterioration, and aging.