The arrest of Venezuelan President Nicolás Maduro has prompted us to enhance electronic shielding to safeguard personal safety.

2026/01/06

0

I. Core Principles: How Materials “Lock” Electromagnetic Waves

The essence of electronic signal leakage is the disorderly propagation of electromagnetic waves. Materials achieve blocking through two key mechanisms:

- Reflection Attenuation: Free electrons on the surface of conductive materials (e.g., metals) generate a reverse electromagnetic field under the action of an electromagnetic field, directly reflecting more than 80% of electromagnetic waves, similar to light reflecting off a mirror. High-frequency scenarios (e.g., WiFi, mobile phone signals) mainly rely on this mechanism, requiring materials with high conductivity (e.g., copper, silver).

- Absorption and Dissipation: Materials with high magnetic permeability or loss characteristics (e.g., ferrites) convert the remaining electromagnetic waves that penetrate the reflection layer into thermal energy, just like a sponge absorbing water. Low-frequency magnetic fields (e.g., electromagnetic radiation from equipment) require such materials for mitigation.

- Continuous Shielding Principle: Any gap will become a “weak point” for signals. It is necessary to coordinate materials and structures to form an unbroken enclosed space, which is the key to achieving a shielding effectiveness of over 99.9%.

II. Key Material Systems and Selection Guide

According to application scenarios and frequency band requirements, mainstream materials can be divided into three categories:

(I) Metal-based Shielding Materials: Main Force for High-Frequency Reflection

| Material Type | Core Performance (1GHz) | Applicable Scenarios | Cost Reference |

|---|---|---|---|

| Galvanized Steel Sheet | SE 30–50 dB, low cost | Walls of general classified computer rooms, equipment enclosures | 50 CNY/m² |

| Copper Foil Composite Material | SE ≥ 70 dB, flexible and conformable | Radar stations, shielding of irregular electronic components | 200 CNY/m² |

| Permalloy (1J85) | Magnetic permeability > 8×10⁴, dedicated for low frequencies | MRI rooms, military command centers | 2,000 CNY/kg |

| Aluminum-Silicon Alloy | Lightweight (60% lighter than steel) | Movable shielding cabins, spacecraft components | 800 CNY/m² |

Technical Key Points: For high-frequency scenarios (1 MHz–10 GHz), the material thickness must satisfy the skin depth formula (δ=√(2/ωμσ)). For example, a galvanized steel sheet with a thickness of more than 0.5 mm can effectively block mobile phone signals.

(II) Flexible Composite Shielding Materials: Protection for Gaps and Irregular Shapes

- Conductive Cloth/Gaskets: Three-layer structure of polyester fiber cloth plated with nickel-copper, SE 40–60 dB, wear-resistant up to 5 million times. Used for shielding curtains and equipment joints; conductive adhesive must be used during installation to ensure close contact.

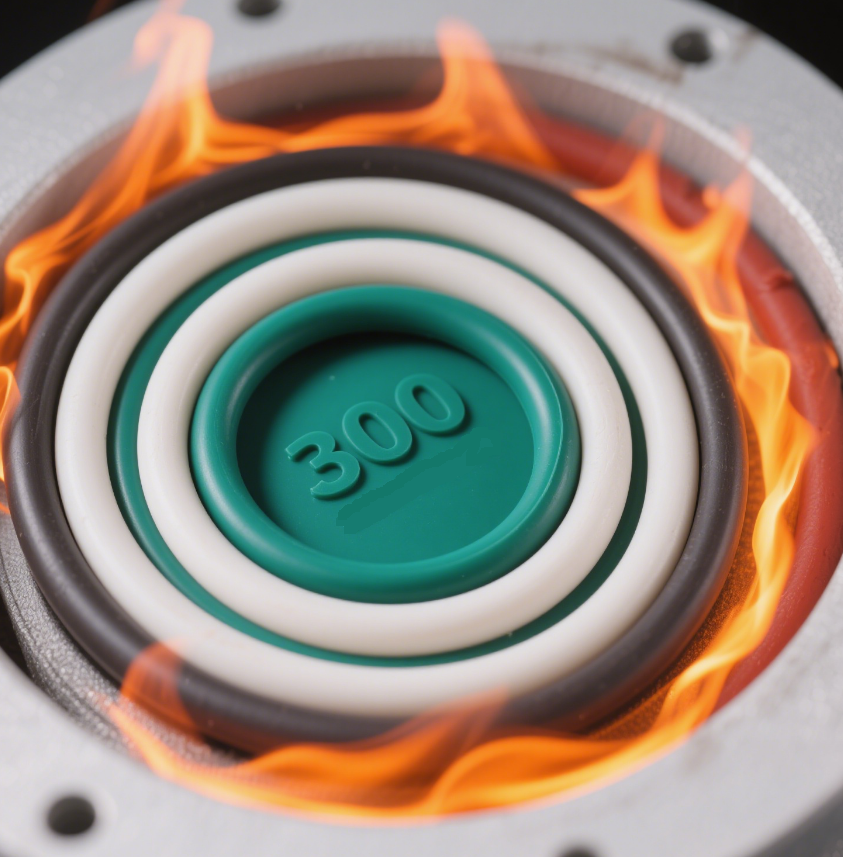

- Conductive Rubber: Silicone rubber added with silver/silver-plated copper particles, SE up to 90–120 dB, with both sealing and moisture-proof functions. Suitable for communication equipment interfaces and gaps in medical instruments.

- Conductive Coating: Resin carrier mixed with copper/silver particles, forming a 20–25 μm conductive film after spraying. It can turn plastic enclosures into shielding bodies, applicable to civil equipment such as routers and remote controls. The film resistance ≤ 0.025 Ω/m².

(III) Emerging Functional Materials: Breakthroughs in High-End Scenarios

- Graphene Coating: Sheet resistance < 1 Ω/sq, thickness only in the micron level, with significant lightweight advantages. However, the cost is as high as 3,000 CNY/kg, and it is currently used in precision electronic cabins of spacecraft.

- Ferrite Bricks and Tiles: Specialized for absorbing low-frequency magnetic fields (30 Hz–100 kHz), often compounded with metal plates to build multi-layer shielding bodies, improving full-frequency band protection capabilities.

- Metallized Fiber Fabric: Polyester cloth with nickel plating, good air permeability, SE 40–60 dB. It is the core material for shielding curtains in classified meeting rooms and radiation-proof work clothes.

III. Key Technologies for System Protection: Coordination of Materials and Structures

Gap Sealing Treatment

- Install beryllium copper finger springs or conductive rubber gaskets at door frames and panel joints, with a compression amount ≥ 3 mm to ensure contact resistance < 0.1 Ω.

- Prioritize laser continuous welding for welding; use silver-filled conductive adhesive for non-welded areas. The overlapping width of joints ≥ 20 mm to form a labyrinth attenuation path.

Shielding Schemes for Special Parts

- Ventilation Openings: Adopt honeycomb waveguide windows with an aperture ≤ λ/10 (e.g., aperture ≤ 10 mm for 3 GHz) and a length ≥ 3 times the aperture to achieve cut-off attenuation.

- Cable Interfaces: Install RF filters on all incoming and outgoing lines; use cables with double shielding layers and 360° lap joint; optical cables need metal armoring and terminate in the shielding box.

- Observation Windows: Double-layer tempered glass with metal wire mesh, light transmittance ≥ 70% and SE ≥ 40 dB, with edges sealed by conductive adhesive strips.

Grounding and System Integration

The shielding body must be connected to an independent grounding system with a grounding resistance < 4 Ω. Equipotential bonding is adopted to eliminate potential differences and avoid signal leakage caused by electrostatic accumulation.

IV. Material Application Schemes for Typical Scenarios

Classified Computer Rooms (SE ≥ 60 dB)

- Walls: 0.5 mm galvanized steel sheet welding + inner layer ferrite bricks; lay copper foil grounding grid on the ground.

- Supporting Facilities: Waveguide ventilation windows + power filters + plug-in type shielding doors (SE ≥ 80 dB).

Internal Shielding of Electronic Equipment

- PCB Boards: SMT patch foam (nickel-copper coating + solder layer) for grounding and buffering, with heat resistance suitable for reflow soldering processes.

- Enclosure Gaps: Conductive cloth gaskets or conductive silica gel dispensing molding, resistant to high and low temperatures (-55℃ ~ +125℃).

Personal Privacy Protection

- Space: Modify existing rooms with conductive coating wallpaper (containing silver particles), and match with shielding curtains to block WiFi signals.

- Equipment: Mobile phone signal shielding bags adopt an aluminum foil + conductive cloth composite structure, with SE ≥ 50 dB.

V. Effectiveness Evaluation and Common Misunderstandings

Professional Indicators

Shielding Effectiveness (SE) is measured in decibels (dB). 30 dB = blocking 99.9% of signals, 60 dB = blocking 99.9999% of signals. Core classified scenarios require 80–100 dB.

Typical Misunderstandings

- Believing that “a single material can shield all frequencies”: Low frequencies require high magnetic permeability materials (permalloy), high frequencies require high conductivity materials (copper), and full-frequency bands require multi-layer composites.

- Ignoring structural integrity: Due to improper gap treatment, the actual SE of DIY shielding rooms may be less than 20 dB, far lower than the claimed value.

- Credulously believing in “health care effects”: Electromagnetic shielding only prevents information leakage and has no scientific correlation with the treatment of “electromagnetic radiation sickness”.