The Applications and Significance of Waterproof Electronic Glues

2025/07/21

0

In the modern electronic era, where devices are exposed to various environmental conditions, waterproof electronic glues have emerged as crucial components. These glues play a vital role in safeguarding electronic components from the detrimental effects of moisture, ensuring the reliable operation and longevity of electronic devices.

Significance of Waterproof Electronic Glues

1. Characteristics of Waterproof Electronic Glues

1.1 Excellent Waterproof Performance

Waterproof electronic glues are engineered to create a highly effective barrier against water penetration. They can withstand exposure to high humidity, splashing water, and even immersion in certain cases. For example, some advanced formulations can maintain their integrity and protective function when submerged in water for extended periods, preventing water from reaching sensitive electronic parts.

1.2 Good Adhesion

They possess strong adhesive properties, allowing them to firmly bond with a wide range of materials commonly used in electronics, such as plastics, metals, and ceramics. This ensures a secure and long – lasting connection, which is essential for the structural stability of electronic assemblies in wet environments. For instance, when bonding a metal casing to a plastic circuit board housing in a waterproof device, the glue must have sufficient adhesion to prevent separation due to water – induced stress.

1.3 Electrical Insulation

To protect the electrical components from short – circuits caused by water – related conductivity issues, waterproof electronic glues offer excellent electrical insulation properties. They act as an insulating layer between different electrical elements, preventing the flow of electricity through unwanted paths. This is particularly important in applications where water and electricity co – exist, like in some underwater electronic devices or those used in humid industrial settings.

1.4 Chemical Resistance

Water – containing environments may also have various chemicals dissolved in them. Good waterproof electronic glues are resistant to common chemicals such as acids, alkalis, and salts, which are often present in rainwater, seawater, or industrial humidity. This chemical resistance ensures that the glue does not degrade or lose its performance over time when exposed to such substances.

2. Common Types of Waterproof Electronic Glues

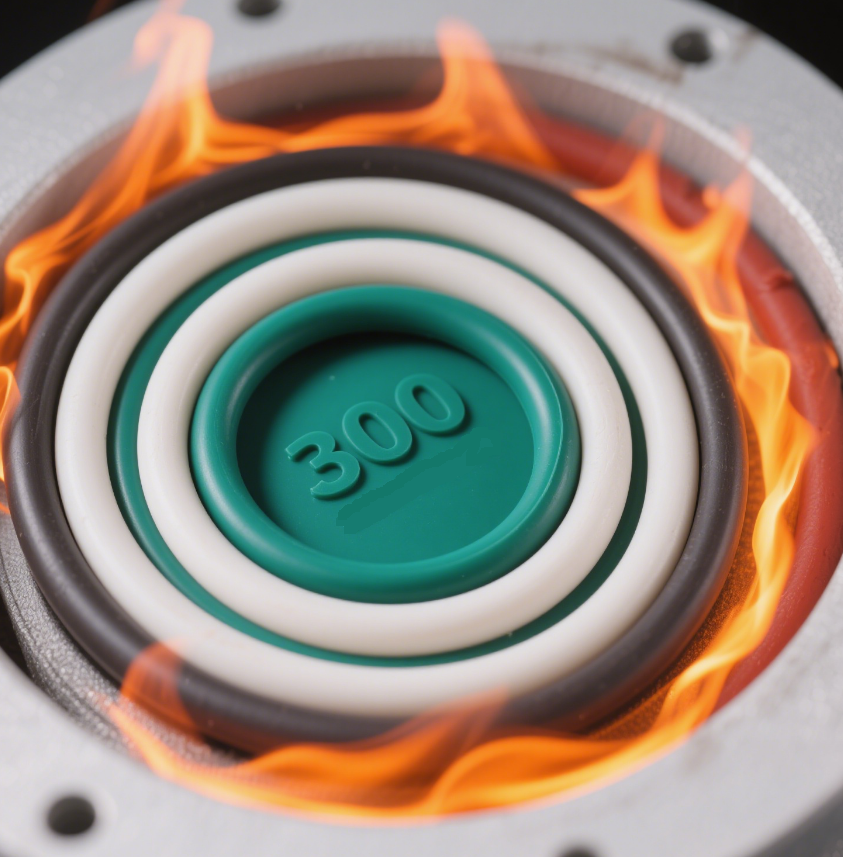

2.1 Silicone – based Waterproof Glues

Silicone glues are widely used in the electronics industry due to their excellent heat resistance, flexibility, and long – term durability. They can cure at room temperature or with the application of heat, forming a rubber – like seal that is highly effective at repelling water. These glues are suitable for applications where the electronic components need to withstand temperature fluctuations, as they maintain their flexibility even at low temperatures. For example, in automotive electronics, where engines generate heat and the vehicle may be exposed to rain, silicone – based waterproof glues are used to protect sensors and control modules.

2.2 Epoxy – based Waterproof Glues

Epoxy glues offer high strength and excellent adhesion. They cure to form a hard, durable seal that can resist mechanical stress and provide reliable waterproofing. Epoxy – based waterproof glues are often used in applications where a strong bond and high – level protection are required, such as in the potting of circuit boards in harsh – environment electronics. They can also be formulated to have good electrical insulation properties, making them suitable for use in high – voltage electronic components.

2.3 Polyurethane – based Waterproof Glues

Polyurethane glues are known for their flexibility, toughness, and good resistance to abrasion. They can conform to irregular surfaces, providing a tight seal. These glues are often used in applications where the electronic device may be subject to vibration or physical impact, such as in mobile devices or portable electronics. Their resistance to water and moisture, combined with their mechanical properties, makes them a popular choice for protecting components in these types of products.

3. Application Scenarios of Waterproof Electronic Glues

3.1 Consumer Electronics

3.1.1 Smartphones and Tablets

In smartphones and tablets, waterproof electronic glues are used to seal the gaps between the display, the housing, and the various internal components. This helps to protect the sensitive circuitry from sweat, rain, and accidental splashes. For example, the glue is applied around the edges of the touchscreen to prevent water from seeping in and causing damage to the underlying electronics. Additionally, it is used to secure and protect the battery compartment, ensuring that the battery remains dry and functional.

3.1.2 Wearable Devices

Wearable devices like smartwatches and fitness trackers are constantly in contact with the user’s skin, which can be sweaty, and are also exposed to the elements. Waterproof electronic glues are used to seal the device’s casing, protect the sensors, and ensure the integrity of the charging ports. In smartwatches, for instance, the glue is applied to create a watertight seal around the heart – rate monitor and other sensors, allowing the device to be worn during activities such as swimming or showering without damage.

3.2 Automotive Electronics

3.2.1 Engine – related Electronics

In the engine compartment of a vehicle, high temperatures, humidity, and splashing water from the road are common. Waterproof electronic glues are used to protect engine control units (ECUs), sensors, and ignition systems. The glue seals the connectors and enclosures of these components, preventing water and moisture from causing short – circuits or corrosion. For example, in oxygen sensors, which are crucial for engine performance and emissions control, waterproof glues are applied to ensure their reliable operation in the harsh engine environment.

3.2.2 Exterior Lighting

Automotive exterior lighting, such as headlights, taillights, and fog lights, are exposed to rain, snow, and mud. Waterproof electronic glues are used to seal the lenses to the housing, preventing water from entering and fogging up the lights. This not only improves the visibility of the lights but also extends their lifespan by protecting the internal bulbs and circuitry from water – related damage.

3.3 Industrial Electronics

3.3.1 Outdoor Control Panels

Industrial control panels installed outdoors are exposed to various weather conditions. Waterproof electronic glues are used to seal the seams and openings of these panels, protecting the internal switches, relays, and circuit boards from rain, dust, and humidity. This ensures the continuous operation of the control panels, which are often critical for the proper functioning of industrial processes.

3.3.2 Underwater Equipment

For underwater equipment such as submersible pumps, remotely operated vehicles (ROVs), and underwater sensors, waterproof electronic glues are essential. These glues are used to pot and seal the entire electronic assembly, providing a watertight barrier that can withstand the high pressure and constant exposure to water in deep – sea or underwater industrial applications. They ensure that the electronics function correctly in the challenging underwater environment.

4. Selection Criteria for Waterproof Electronic Glues

4.1 Application Requirements

The specific application of the electronic device determines the type of waterproof glue needed. For example, if the device will be exposed to high temperatures, a heat – resistant glue like a silicone – based one may be more suitable. If it requires a very strong bond and high mechanical strength, an epoxy – based glue could be the better choice. In applications where flexibility and vibration resistance are important, polyurethane – based glues are often preferred.

4.2 Compatibility with Materials

The glue must be compatible with the materials it will be bonding. Different electronic components are made of various materials, and the glue should adhere well to these materials without causing any chemical reactions or damage. For example, some glues may not bond well with certain plastics, so it is crucial to select a glue that is compatible with the specific plastic, metal, or ceramic used in the electronic device.

4.3 Environmental Conditions

The environmental conditions the device will be exposed to play a significant role in glue selection. If the device will be used in a highly humid or salty environment, a glue with excellent chemical resistance, such as one that can withstand saltwater corrosion, is necessary. In extreme cold or hot environments, the glue should maintain its performance and adhesion properties.

In conclusion, waterproof electronic glues are indispensable in modern electronics. Their ability to provide waterproofing, adhesion, electrical insulation, and chemical resistance makes them essential for protecting electronic components in a wide range of applications. By carefully selecting the right type of waterproof glue based on application requirements, material compatibility, and environmental conditions, manufacturers can ensure the reliability and longevity of their electronic products, even in the harshest of environments.