Silicone Sealant in Medical Equipment

2025/06/16

0

In the intricate and highly specialized realm of medical equipment, the choice of materials can make a significant difference in performance, safety, and longevity. Among these materials, silicone sealant has emerged as a crucial component, playing a vital role in various medical devices and equipment. This article will explore the applications, advantages, challenges, and future trends of silicone sealant in medical equipment.

Applications of Silicone Sealant in Medical Equipment

1. Sealing and Protection

One of the primary applications of silicone sealant in medical equipment is for sealing purposes. In devices such as infusion pumps, ventilators, and medical imaging equipment, silicone sealant is used to create airtight and watertight seals. This helps prevent the leakage of fluids, gases, or other substances, ensuring the proper functioning of the equipment and protecting patients from potential hazards. For example, in infusion pumps, a reliable seal is essential to maintain the accurate delivery of medications. A tiny leak could lead to incorrect dosing, which can have serious consequences for patients. Silicone sealant provides a durable and flexible seal that can withstand the rigors of continuous use and varying environmental conditions.

2. Adhesion and Bonding

Silicone sealant also serves as an excellent adhesive for bonding different components of medical equipment. It can effectively bond various materials commonly used in medical devices, such as plastics, metals, and glass. In the assembly of catheters, syringes, and other disposable medical products, silicone sealant ensures a secure connection between parts, enhancing the structural integrity of the devices. This is especially important for maintaining the sterility of the products. A strong bond created by silicone sealant helps prevent the entry of contaminants, reducing the risk of infection for patients.

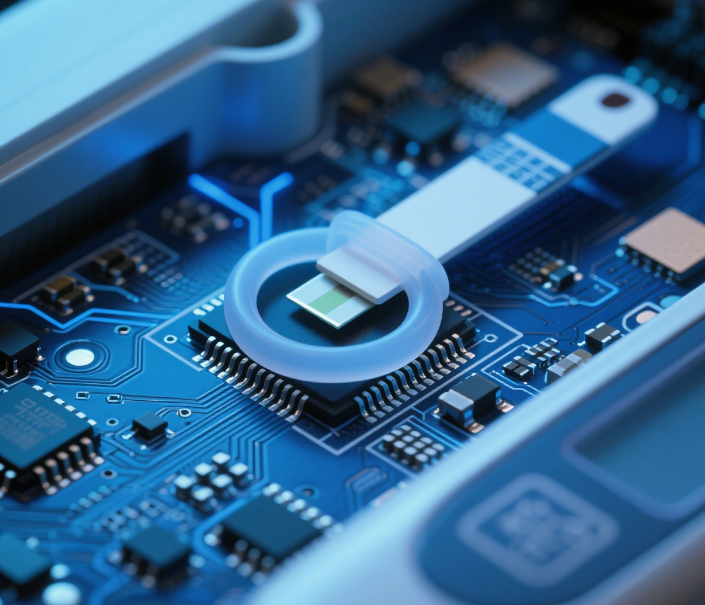

3. Insulation and Electrical Protection

In medical equipment that involves electrical components, such as electrocardiographs (ECGs) and defibrillators, silicone sealant is used for insulation and electrical protection. It has excellent electrical insulating properties, which can prevent electrical shorts and ensure the safe operation of the equipment. Additionally, silicone sealant can protect electrical components from moisture, dust, and other environmental factors that could potentially damage the electronics. This helps extend the lifespan of the equipment and reduces the likelihood of malfunctions during critical medical procedures.

4. Gasket and O – ring Applications

Silicone sealant is often used in the production of gaskets and O – rings for medical equipment. These components are essential for creating seals in joints and connections, preventing the leakage of fluids or gases. Silicone gaskets and O – rings offer high flexibility, resilience, and chemical resistance, making them suitable for a wide range of medical applications. They can withstand repeated compression and expansion without losing their sealing properties, ensuring long – term reliability in medical equipment.

Advantages of Silicone Sealant in Medical Equipment

1. Biocompatibility

One of the most significant advantages of silicone sealant in medical applications is its biocompatibility. Silicone is generally well – tolerated by the human body, making it suitable for use in devices that come into direct or indirect contact with patients. It does not cause significant allergic reactions or tissue irritation, which is crucial for ensuring patient safety. This property allows silicone sealant to be used in a variety of medical applications, from external devices to those implanted within the body.

2. Chemical Resistance

Silicone sealant exhibits excellent chemical resistance, which is essential in the medical field where equipment may be exposed to a variety of disinfectants, cleaning agents, and bodily fluids. It can resist degradation from chemicals such as alcohol, hydrogen peroxide, and common medical solvents, ensuring that the sealant remains intact and functional over time. This chemical resistance also helps maintain the integrity of the medical equipment, preventing damage from chemical exposure.

3. Temperature Resistance

Medical equipment often needs to operate in a wide range of temperatures, from cold storage conditions to warm clinical environments. Silicone sealant has a broad temperature resistance range, allowing it to maintain its properties and performance in extreme cold or heat. It remains flexible and resilient even at low temperatures, preventing cracking or brittleness, and can withstand high temperatures without melting or degrading. This temperature resistance makes silicone sealant a reliable choice for medical equipment used in various settings.

4. Durability and Longevity

Silicone sealant is known for its durability and long – term performance. It has excellent resistance to aging, UV radiation, and mechanical stress, which are common factors that can affect the lifespan of medical equipment. A durable sealant ensures that the medical device remains functional and safe for an extended period, reducing the need for frequent replacements and maintenance. This not only saves costs but also minimizes the potential risks associated with equipment failures during medical procedures.

Challenges Associated with Silicone Sealant in Medical Equipment

1. Regulatory Compliance

The medical device industry is highly regulated, and ensuring that silicone sealant meets all relevant regulatory requirements is a significant challenge. Different countries and regions have specific standards and guidelines regarding the use of materials in medical equipment, including requirements for biocompatibility, toxicity, and sterilization. Manufacturers need to invest significant time and resources in testing and validating their silicone sealant products to ensure compliance with these regulations. Failure to meet regulatory requirements can result in product recalls, legal issues, and damage to a company’s reputation.

2. Contamination Risks

Although silicone sealant is generally biocompatible, there is still a risk of contamination during the manufacturing process. Even trace amounts of impurities or contaminants in the sealant can pose a risk to patient safety. Ensuring a clean manufacturing environment and implementing strict quality control measures are essential to minimize the risk of contamination. Additionally, during the application of silicone sealant in medical equipment assembly, care must be taken to prevent the introduction of foreign particles or substances that could compromise the integrity of the seal or the sterility of the device.

3. Compatibility with Other Materials

While silicone sealant can bond well with many materials, there may be compatibility issues with certain specialized or newly developed materials used in medical equipment. These compatibility issues can lead to poor adhesion, delamination, or chemical reactions between the sealant and other components. Manufacturers need to carefully evaluate the compatibility of silicone sealant with all the materials used in their medical devices to ensure optimal performance and reliability.

Future Trends of Silicone Sealant in Medical Equipment

1. Advancements in Biocompatibility

As the medical field continues to evolve, there is a growing demand for even higher levels of biocompatibility in medical materials. Future research and development efforts for silicone sealant are likely to focus on improving its biocompatibility further. This could involve developing new formulations that are even more compatible with the human body, reducing the risk of long – term tissue reactions or inflammation. Additionally, there may be a push towards creating silicone sealants that can actively promote tissue healing or integration, especially for use in implantable medical devices.

2. Smart and Functional Silicone Sealants

The concept of smart materials is becoming increasingly popular in the medical industry, and silicone sealant is no exception. Future silicone sealants may incorporate smart features such as self – healing capabilities, sensors for detecting seal integrity, or the ability to release drugs or other therapeutic agents. For example, a self – healing silicone sealant could automatically repair small cracks or damages, ensuring the continued functionality of the medical equipment. Sensors integrated into the sealant could provide real – time information about the condition of the seal, allowing for proactive maintenance and reducing the risk of equipment failures.

3. Sustainability and Environmentally Friendly Formulations

With a growing emphasis on sustainability in all industries, the medical device industry is also looking for more environmentally friendly materials. Future silicone sealant products may be developed using more sustainable manufacturing processes and raw materials. This could include the use of renewable resources, reducing the use of harmful solvents or chemicals, and improving the recyclability of silicone – based medical devices. Developing sustainable silicone sealant formulations not only benefits the environment but also aligns with the ethical and social responsibilities of the medical device industry.

In conclusion, silicone sealant plays an indispensable role in medical equipment, offering a wide range of applications and numerous advantages. However, it also faces several challenges related to regulatory compliance, contamination risks, and material compatibility. Looking ahead, the future of silicone sealant in medical equipment is promising, with trends pointing towards enhanced biocompatibility, the development of smart and functional materials, and a focus on sustainability. As the medical field continues to advance, silicone sealant will likely continue to evolve to meet the ever – changing needs of medical equipment manufacturers and patients alike.