PDMS Membranes: A Multifunctional Material Solution for the Biomedical Field

2025/12/23

0

I. Core Material Advantages: Laying the Foundation for Biomedical Applications

The three core properties of PDMS (Polydimethylsiloxane) membranes—biological inertness, non-toxicity, and high flexibility—fundamentally address the key pain points associated with the contact between biomedical materials and human bodies/biological samples:

- Biological inertness ensures that it does not trigger immune rejection or inflammatory responses in in vivo or in vitro environments, nor does it chemically react with biological media such as blood and tissue fluid, thus guaranteeing stability for long-term use.

- Non-toxicity has passed biocompatibility tests (e.g., cytotoxicity tests, skin irritation tests), meeting the stringent requirements for direct contact with biological samples in scenarios such as in vivo implantation and in vitro diagnostic consumables.

- Excellent flexibility enables it to adapt to complex scenarios (e.g., curved surface fitting of implantable devices, miniaturized design of portable diagnostic instruments), while its superior mechanical stability prevents damage caused by bending or stretching.

II. Three Core Application Scenarios: Full-chain Coverage from Diagnosis to Treatment

1. In Vitro Diagnostic (IVD) Consumables: The “Molecular Screening Barrier” for Accurate Detection

The core value of PDMS membranes in the IVD field lies in selective permeability and high-efficiency response, perfectly meeting the dual requirements of detection equipment for precision and speed:

- Targeted permeability: It can accurately screen target analytes such as O₂, CO₂, and glucose, and effectively block impurities in blood including proteins, red blood cells, and platelets, avoiding sensor contamination or detection signal interference to ensure the accuracy of test results (e.g., accurate measurement of pO₂ and pCO₂ levels in arterial blood in blood gas analyzers).

- Ultra-thinning upgrade: Through process optimization, an ultra-thin thickness of 1–5 μm is achieved, which significantly reduces molecular permeability resistance and shortens the detection response time to a few seconds, satisfying the rapid diagnosis needs of point-of-care testing (POCT) scenarios (e.g., rapid fingertip blood glucose reading in glucose monitors).

- Application extension: It can also be used as a separation membrane component in IVD devices for immunoassays and nucleic acid testing, improving the stability and sensitivity of detection systems.

2. Drug Controlled-release Carriers: The “Precision Regulating Valve” for Smart Drug Delivery

PDMS Membranes: A Multifunctional Material Solution for the Biomedical Field

By precisely regulating the structural parameters of PDMS membranes (crosslinking degree, porosity, and thickness), “on-demand customization” of drug release can be achieved, making it a core material for implantable and topical drug delivery systems:

- Controllable release rate: The higher the crosslinking degree, the denser the membrane structure, and the lower the drug permeability rate; adjusting the porosity can further optimize the release profile, realizing long-term stable release ranging from several days to months (e.g., implantable drug delivery systems for osteoporosis treatment can release drugs once a month, reducing the frequency of administration for patients).

- Improved treatment safety: It avoids the “peak-valley fluctuations of blood drug concentration” associated with traditional administration methods, maintains the effective therapeutic concentration of drugs in the body, reduces toxic and side effects caused by excessive doses, and lowers the risk of infection from administration operations.

- Scenario adaptability: Its flexibility allows it to fit the curved surfaces of human tissues (e.g., skin, visceral surfaces), and it can be applied in topical skin patches, ophthalmic drug delivery devices, and coating membranes for implantable sustained-release microspheres, with broad application prospects in cancer treatment, chronic disease management, and postoperative rehabilitation.

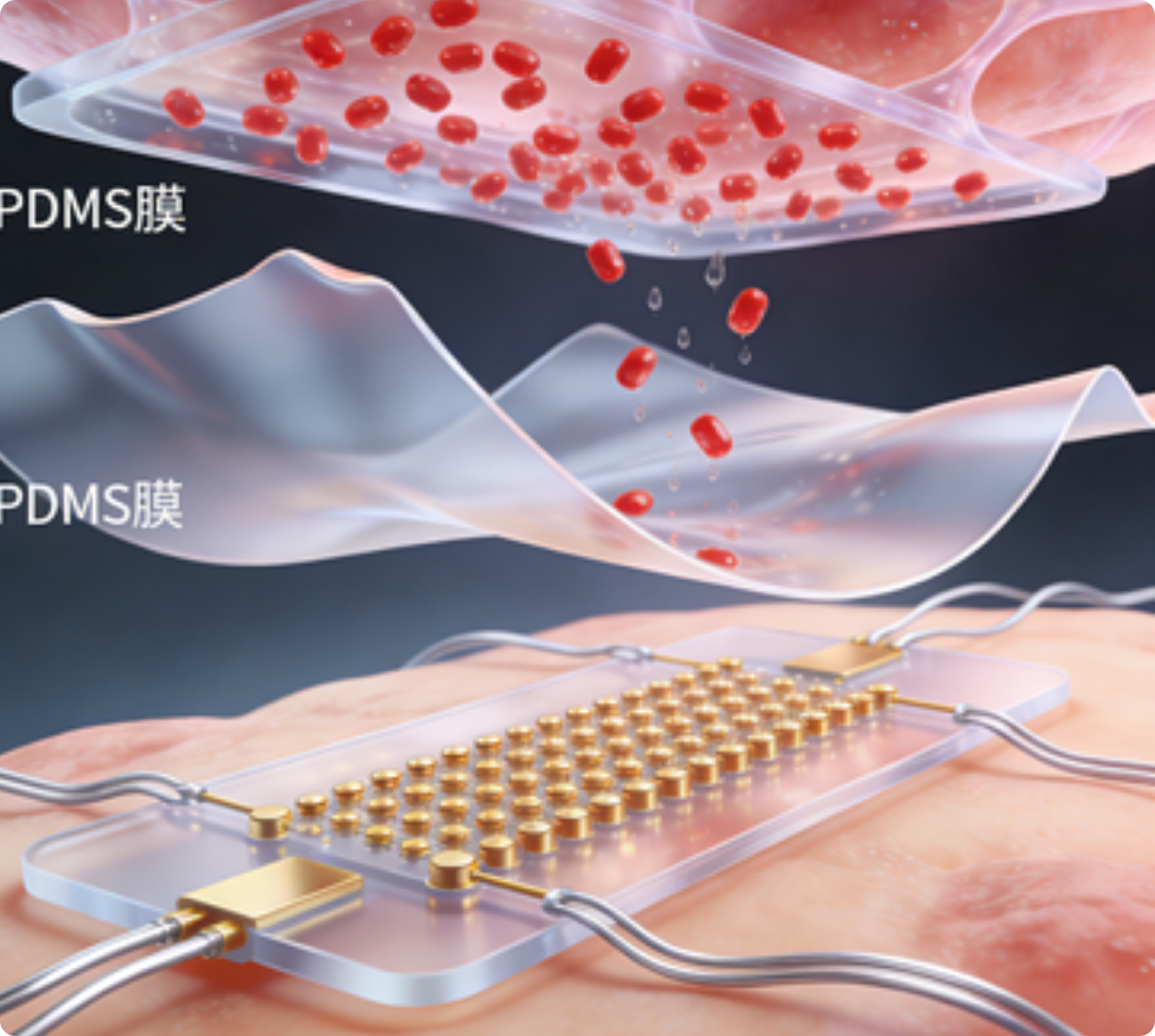

3. Tissue Engineering Scaffolds: The “Bionic Microenvironment Carrier” for Regenerative Repair

Porous PDMS membranes have become an ideal scaffold material for simulating the in vivo cell growth environment due to structural bionics and functional adaptability:

- Cell-friendly properties: The porous structure (with pore size adjustable to the micrometer scale) provides physical support for cell adhesion and proliferation, and its excellent cytocompatibility ensures stable cell growth on the scaffold surface; meanwhile, the material surface can be modified (e.g., grafting collagen and integrin) to further enhance cell adhesion capacity.

- Bidirectional permeability: High gas permeability and hydrophilicity (optimizable through surface modification) allow oxygen and nutrients (e.g., glucose, amino acids) to freely diffuse into cells, while timely excreting metabolic wastes (e.g., lactic acid, carbon dioxide), simulating the material exchange mechanism of in vivo tissues.

- Regenerative repair applications: In the field of skin repair, porous PDMS membranes can serve as wound dressing scaffolds to promote epidermal cell proliferation and dermal tissue regeneration, accelerating wound healing and reducing scar formation; in fields such as corneal regeneration and cartilage repair, they can act as cell culture carriers to construct bionic tissue engineering grafts, providing new solutions for organ repair.

III. Industry Value and Development Trends: From Material Innovation to Medical Upgrading

With its multi-functional adaptability, PDMS membranes are driving three major upgrades in the biomedical field:

- Diagnostic efficiency upgrade: It helps IVD devices move towards “rapid, accurate, and miniaturized” development, promoting the popularization of point-of-care testing technology.

- Treatment model upgrade: It realizes the transformation of drug administration from “passive delivery” to “active controlled release”, improving the treatment experience and efficacy of chronic and intractable diseases.

- Regenerative medicine breakthrough: It provides high-performance bionic materials for tissue engineering and organ transplantation, reduces the risk of immune rejection, and accelerates the clinical translation of regenerative repair technologies.

In the future, with the integration of PDMS membrane modification technologies (e.g., surface functionalization, composite membrane preparation) and technologies such as 3D printing and microfluidics, its applications in the biomedical field will be further expanded to high-end scenarios including single-cell analysis, organ chips, and targeted drug delivery, continuously injecting innovative momentum into the healthcare industry.

As a professional enterprise dedicated to the R&D and production of PDMS membranes, Dongguan Yusheng Technology Co., Ltd. offers product customization services. For cooperation or to learn more technical details, please contact us via email : zhengzhen@nqrubber.com.