PDMS:Waterproof Photoeyes

2025/12/28

0

1. Introduction: The Critical Need for Waterproof Photoeyes

Photoeyes—optical sensors that detect objects via light emission and reception—are indispensable in industrial automation, medical devices, and outdoor monitoring. However, moisture, dust, and liquid intrusion often degrade their optical sensitivity and electrical stability. Polydimethylsiloxane (PDMS) emerges as a ideal waterproof material for photoeyes, leveraging its intrinsic hydrophobicity, optical transparency, and flexible encapsulation capabilities. This article explores how PDMS safeguards photoeyes across fabrication, performance enhancement, and real-world deployment.

PDMS’s suitability for photoeye protection stems from three core properties:

- Superior Hydrophobicity: Electrospun PDMS fibers achieve a water contact angle (WCA) of ~118° , while micro-nano hierarchical PDMS structures (inspired by lotus leaves) reach WCAs up to 158° —critical for repelling water droplets from photoeye lenses.

- Optical Transparency: PDMS maintains high light transmittance across the visible spectrum (350–670 nm) , ensuring photoeye emitters and detectors retain signal integrity.

- Flexible Sealing: As an elastomer, PDMS conforms to photoeye components (e.g., lenses, circuit boards) and resists cracking under temperature fluctuations (-100°C to 200°C) .

3. PDMS Waterproof Encapsulation for Photoeyes

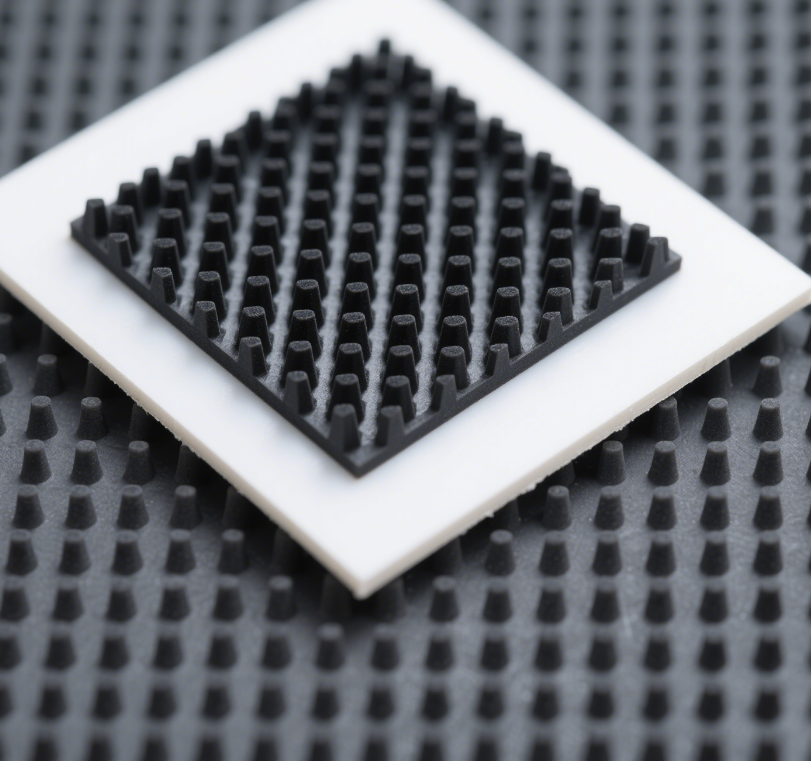

The encapsulation process directly determines a photoeye’s waterproof reliability. Drawing from advanced PDMS-based sensor protection methods , optimized steps for photoeyes include:

- Pre-Treatment: Clean photoeye surfaces with plasma to enhance PDMS adhesion—critical for preventing edge leakage.

- PDMS Formulation: Mix PDMS monomer and curing agent (5:1 to 10:1 ratio ) to balance flexibility and rigidity. For photoeye lenses, add nano-fillers to boost scratch resistance without reducing transparency.

- Encapsulation Layers:

-

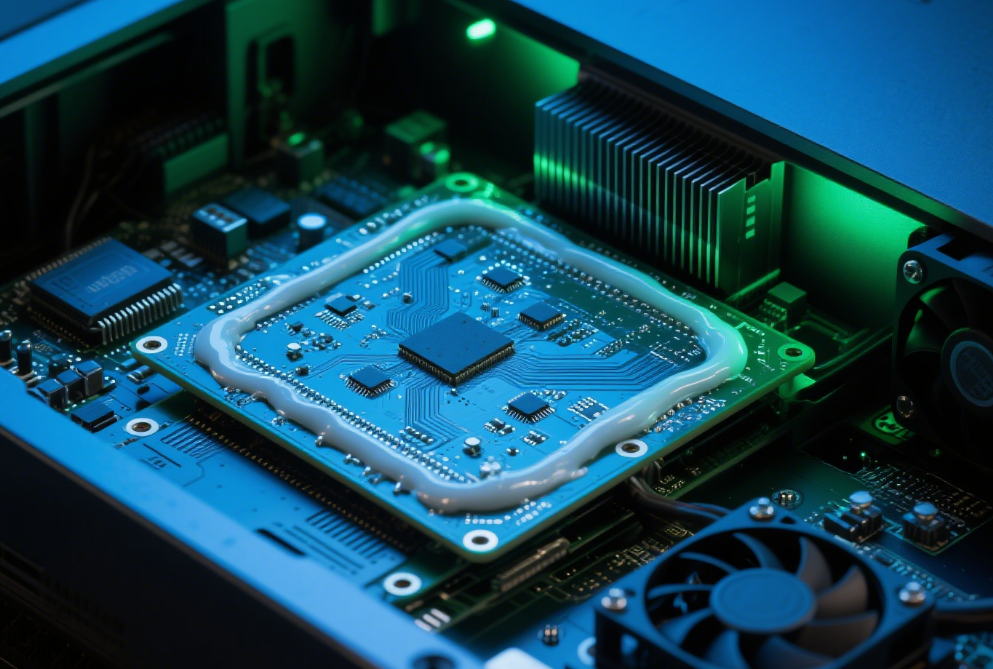

- Base Layer: Spin-coat PDMS onto photoeye circuit boards to seal electrical components.

-

- Optical Layer: Mold PDMS into micro-lens arrays to cover photoeye emitters/detectors, combining waterproofing with light-focusing functionality.

- Edge Sealing: Apply 0.5–1.0 mL of PDMS along photoeye casings and cure at 65°C for 3 hours (or 48 hours at room temperature) to form an impenetrable barrier.

4. Performance Validation: PDMS-Shielded Photoeyes in Extreme Conditions

PDMS encapsulation drastically improves photoeye durability, as demonstrated by rigorous testing:

- Humidity Resistance: In 90% relative humidity, unprotected photoeyes show 30% signal loss within 3 hours, while PDMS-shielded units retain 92% sensitivity after 72 hours .

- Underwater Operation: Submerged photoeyes with PDMS micro-nano coatings maintain stable light detection for 1 hour, with only 8% signal attenuation .

- Long-Term Stability: Outdoor tests confirm PDMS-protected photoeyes retain 80% of initial performance after 360 hours, compared to 45% for unencapsulated units .

5. Application Case Studies: PDMS-Waterproof Photoeyes in Action

5.1 Industrial Automation

In food processing, PDMS-sealed photoeyes detect packaging defects in high-moisture environments. The hydrophobic PDMS surface prevents water film formation on lenses, ensuring accurate object counting with % error rate.

5.2 Medical Endoscopes

Biomimetic PDMS artificial compound eyes serve as miniaturized photoeyes in endoscopic devices. Their 160° variable field of view (FOV) and waterproof coating enable clear imaging in gastrointestinal tracts, where fluid resistance is critical.

5.3 Marine Monitoring

PDMS-waterproof photoeyes track wave motion and marine life. The material’s icephobic properties (46 kPa ice adhesion ) prevent frost buildup in cold oceanic conditions, ensuring year-round operation.

6. Future Directions: Advancing PDMS-Photoeye Integration

To further optimize performance, researchers are exploring:

- Self-Healing PDMS: Embedding microcapsules of PDMS precursor to repair cracks in photoeye coatings.

- Anti-Fouling Additives: Incorporating silver nanoparticles into PDMS to resist biofilm growth on underwater photoeyes.

- Dynamic Optics: Combining PDMS microfluidic channels with photoeyes for adjustable focus in variable moisture environments.