Nanoparticle-Doped PDMS Membranes: An Innovative Breakthrough in Gas Separation

2025/12/01

0

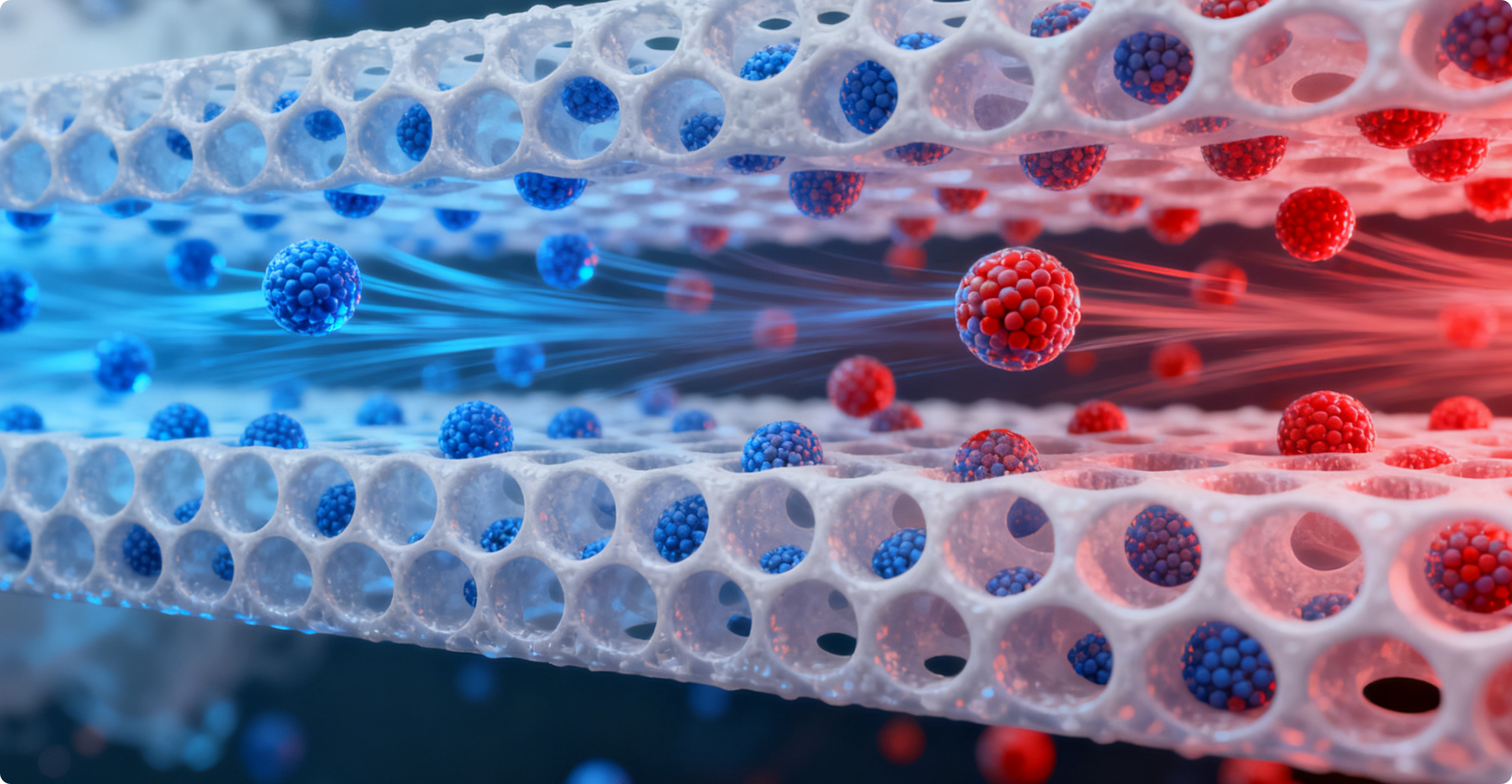

In numerous fields such as industrial gas separation, environmental governance, and energy development, efficient gas separation technology has always been a core focus of research. Traditional PDMS (polydimethylsiloxane) membranes, despite their application in gas separation due to good gas permeability, exhibit relatively low gas separation selectivity, making them unable to meet the high-precision separation requirements in complex scenarios. However, the emergence of nanoparticle-doped PDMS membranes has effectively addressed this critical issue, providing a new direction for the upgrading and iteration of gas separation technology.

I. Preparation Principle of Nanoparticle-Doped PDMS Membranes

The preparation of PDMS membranes uses PDMS prepolymer as the basic raw material. By introducing different types of nanoparticles (such as MOFs, GO, SiO₂, etc.), doped composite membranes are formed through a casting and curing process. The specific process can be divided into the following key steps:

-

Raw Material Pretreatment: First, the PDMS prepolymer is stirred for homogenization to ensure uniform texture, laying a solid foundation for the subsequent dispersion of nanoparticles. Meanwhile, pretreatment is carried out according to the characteristics of different nanoparticles. For example, MOFs (metal-organic frameworks) undergo activation treatment to remove impurity molecules in their pores and enhance their adsorption performance; GO (graphene oxide) is subjected to ultrasonic dispersion to break its agglomerated state and ensure uniform distribution in the PDMS matrix.

-

Nanoparticle Dispersion and Mixing: The pretreated nanoparticles are slowly added to the PDMS prepolymer in a certain proportion. A combination of mechanical stirring and ultrasonic dispersion is used to fully disperse the nanoparticles in the prepolymer system, forming a stable mixed solution. This step is crucial: if the nanoparticles are not uniformly dispersed, defects will exist in the internal structure of the composite membrane, affecting its gas separation performance.

-

Casting and Forming: The uniform mixed solution is poured into a specific mold or the carrier belt of a casting machine. By controlling the casting speed and the height of the doctor blade, the mixed solution forms a thin film with uniform thickness. The casting speed and film thickness need to be precisely adjusted according to actual application requirements. Generally, the thickness of composite membranes used for gas separation ranges from several micrometers to tens of micrometers.

-

Curing Treatment: The cast film is placed in an oven for curing reaction at a specific temperature. The curing temperature and time are determined based on the curing characteristics of the PDMS prepolymer and the thermal stability of the nanoparticles. Typically, the curing temperature is between 60-120℃, and the curing time is 2-8 hours. During the curing process, the PDMS prepolymer undergoes a cross-linking reaction to form a stable three-dimensional network structure. At the same time, the nanoparticles are firmly embedded in the PDMS matrix, eventually forming the nanoparticle-doped PDMS composite membrane.

II. Enhancing Effects of Different Nanoparticles on Gas Separation Performance of PDMS Membranes

(1) MOFs (Metal-Organic Frameworks)

MOFs are porous materials with periodic network structures formed by the self-assembly of metal ions or metal clusters and organic ligands through coordination bonds. They possess unique advantages such as large specific surface area, adjustable pore size, and diverse structures. When doped into PDMS membranes, they significantly enhance the gas separation performance of the membranes:

-

Improving CO₂/N₂ Selectivity: There are strong electrostatic interactions and coordination effects between the metal ions in MOFs and CO₂ molecules, enabling the selective adsorption of CO₂ molecules. Meanwhile, the porous structure of MOFs provides specific channels for gas molecule transport, and the diffusion coefficient of CO₂ molecules in MOF pores is much higher than that of N₂ molecules. After MOFs are doped into PDMS membranes, the membrane’s CO₂ adsorption capacity and selective transport capacity are greatly improved, leading to a significant increase in CO₂/N₂ selectivity. Studies have shown that the CO₂/N₂ selectivity of some MOF-doped PDMS membranes can be increased to over 50, which is much higher than that of pure PDMS membranes (usually with CO₂/N₂ selectivity between 10-20).

-

Maintaining Good Gas Permeability: The porous structure of MOFs not only facilitates the selective adsorption and transport of gases but also forms additional gas transport channels in the PDMS matrix, reducing the transport resistance of gas molecules within the membrane. Thus, while improving selectivity, the good gas permeability of the membrane is maintained.

(2) GO (Graphene Oxide)

GO is a two-dimensional nanomaterial with a single-layer or few-layer structure obtained by oxidizing and exfoliating graphite. Its surface contains a large number of oxygen-containing functional groups such as hydroxyl, carboxyl, and epoxy groups. These functional groups provide favorable conditions for the combination of GO with the PDMS matrix and the interaction with gas molecules:

-

Enhancing Gas Separation Selectivity: The two-dimensional lamellar structure of GO can form a “barrier-like” effect in the PDMS membrane. When gas molecules transport within the membrane, they need to bypass the GO lamellae, extending the transport path. Due to differences in molecular size and polarity among different gas molecules, their transport resistances within the membrane also vary. For gas molecules with larger molecular size or weaker polarity (such as N₂, CH₄, etc.), the increase in transport resistance is more significant; while for gas molecules with smaller molecular size or stronger polarity (such as CO₂, H₂O, etc.), the increase in transport resistance is relatively small. As a result, the gas separation selectivity of the membrane is improved.

-

Improving Membrane Mechanical Properties: GO has excellent mechanical strength and flexibility. When doped into PDMS membranes, it can form a strong interface bonding force with the PDMS matrix, effectively inhibiting the deformation and damage of the membrane during use, and improving the mechanical stability and service life of the membrane.

(3) SiO₂ (Silicon Dioxide)

SiO₂ nanoparticles are common inorganic nanomaterials with advantages such as good chemical stability, easy surface modification, and low cost, and have been widely used in the modification of PDMS membranes:

-

Regulating Membrane Pore Structure: SiO₂ nanoparticles have a small particle size (usually between several nanometers to tens of nanometers). When doped into PDMS membranes, they can be uniformly dispersed in the PDMS matrix, regulating the pore structure of the membrane. By changing the particle size and doping amount of SiO₂ nanoparticles, the average pore size of the membrane can be adjusted within a certain range, thereby achieving selective separation of different gas molecules. For example, when it is necessary to separate small-molecule gases (such as H₂) and large-molecule gases (such as CH₄), appropriate particle sizes of SiO₂ nanoparticles can be selected to make the membrane pores more conducive to the transport of H₂, improving H₂/CH₄ selectivity.

-

Enhancing Membrane Thermal Stability: Pure PDMS membranes have relatively poor thermal stability and are prone to thermal aging at higher temperatures, resulting in a decline in gas separation performance. SiO₂ nanoparticles have good thermal stability. When doped into PDMS membranes, they can effectively inhibit the thermal movement of PDMS molecular chains at high temperatures, reduce thermal shrinkage and structural damage of the membrane, thereby improving the thermal stability of the membrane and expanding its operating temperature range.

III. Application Scenarios of Nanoparticle-Doped PDMS Membranes

(1) Natural Gas Purification

During natural gas extraction, natural gas usually contains a certain amount of acidic gases such as CO₂ and H₂S. These acidic gases not only reduce the calorific value of natural gas but also cause corrosion to transmission pipelines and equipment. Nanoparticle-doped PDMS membranes (especially MOF-doped PDMS membranes) have excellent CO₂/N₂ selectivity and good gas permeability, and can be used for the removal of CO₂ from natural gas. The use of membrane separation technology to remove CO₂ from natural gas has advantages such as simple equipment, small footprint, convenient operation, and no secondary pollution. It can effectively improve the purity of natural gas and reduce transmission costs and equipment corrosion risks.

(2) Flue Gas CO₂ Capture

Flue gas emitted during industrial production contains a large amount of CO₂, and the emission of this CO₂ is one of the main causes of global warming. Therefore, the capture and sequestration of CO₂ from flue gas have become an important research topic in the field of environmental protection. Nanoparticle-doped PDMS membranes have broad application prospects in flue gas CO₂ capture. The main components of flue gas are N₂ (accounting for approximately 75%) and CO₂ (accounting for approximately 15-20%), along with small amounts of gases such as O₂ and H₂O. MOF-doped PDMS membranes have good selective adsorption and transport performance for CO₂, enabling efficient separation of CO₂ from flue gas. Compared with the traditional amine absorption method, membrane separation technology has the advantages of low energy consumption, simple operation, and no problems such as amine solution degradation and equipment corrosion, making it a promising flue gas CO₂ capture technology.

(3) Biogas Purification

Biogas (such as marsh gas) is a clean energy source produced by biomass fermentation, whose main components are CH₄ (accounting for approximately 50-70%) and CO₂ (accounting for approximately 30-50%). To improve the calorific value and utilization value of biogas, it is necessary to purify the biogas and remove CO₂. Nanoparticle-doped PDMS membranes can be used for the removal of CO₂ from biogas. Through membrane separation technology, CO₂ in biogas is separated, increasing the purity of CH₄ to over 95%, which meets the application standards of natural gas. In addition, membrane separation technology can also remove small amounts of impurity gases such as H₂S from biogas, further improving the quality of biogas.

IV. Future Development Prospects of Nanoparticle-Doped PDMS Membranes

Although nanoparticle-doped PDMS membranes have achieved significant research progress in the field of gas separation, there are still some issues that need to be further addressed, and they also face broad development opportunities:

-

Optimizing Nanoparticle Dispersion: Currently, the dispersion of nanoparticles in the PDMS matrix remains one of the key factors affecting the performance of composite membranes. Some nanoparticles are prone to agglomeration due to their high surface energy, leading to defects in the composite membrane and affecting its gas separation performance and mechanical properties. Future research can improve the compatibility between nanoparticles and the PDMS matrix through surface modification of nanoparticles (such as grafting organic functional groups, coating polymers, etc.), thereby enhancing the uniform dispersion of nanoparticles in the PDMS matrix.

-

Developing New Nanoparticle Materials: With the continuous development of materials science, more and more new nanoparticle materials with unique structures and properties are emerging. In the future, further development of new nanoparticle materials with higher selectivity, better stability, and lower cost can be carried out, and their application in the modification of PDMS membranes can continuously improve the gas separation performance of composite membranes and expand their application scope.

-

Research on Large-Scale Preparation Technology: At present, the preparation of nanoparticle-doped PDMS membranes is mostly in the laboratory research stage, and the large-scale preparation technology is not yet mature. In the future, it is necessary to strengthen research on large-scale preparation processes of composite membranes, develop efficient and stable large-scale production equipment and processes, reduce production costs, and promote the wide application of nanoparticle-doped PDMS membranes in industrial fields.

-

Research and Development of Multifunctional Composite Membranes: In addition to gas separation performance, future efforts can also combine other functions of nanoparticles (such as antibacterial, catalytic, photoresponsive, etc.) with the characteristics of PDMS membranes to develop multifunctional composite membranes. For example, doping nanoparticles with antibacterial properties (such as Ag nanoparticles) into PDMS membranes to prepare gas separation membranes with antibacterial functions, which can be used for gas purification in the medical field; doping nanoparticles with catalytic properties into PDMS membranes to prepare composite membranes with integrated catalytic-separation functions, which can be used for product separation and purification in chemical reaction processes.

In conclusion, nanoparticle-doped PDMS membranes, with their excellent gas separation performance, good stability, and broad application prospects, have become a research hotspot in the field of gas separation. With the continuous deepening of research and continuous breakthroughs in technology, nanoparticle-doped PDMS membranes will surely play a more important role in industrial production, environmental protection, and energy development, providing strong technical support for solving global energy and environmental issues.

Dongguan Yusheng Technology specializes in the R&D and production of PDMS membranes, and also provides customization services.