Market Applications of Thermal Conductive Potting Adhesives

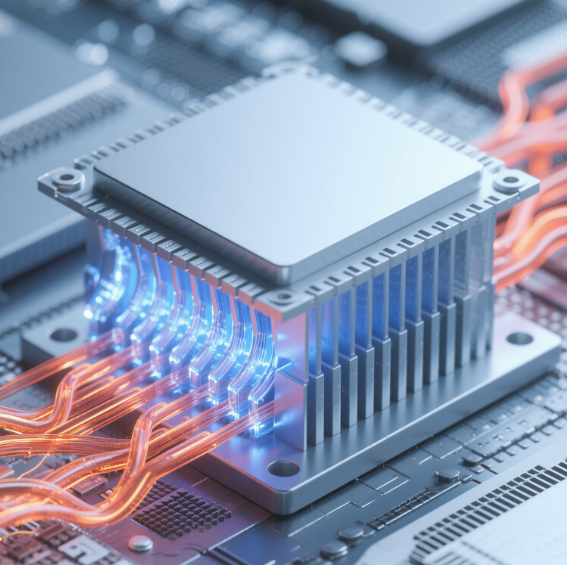

Power Modules

During operation, power supplies generate substantial heat, which can severely impact their performance and lifespan if not dissipated promptly. High-performance thermal conductive potting adhesives efficiently transfer heat from the interior of power modules, ensuring the power supply operates efficiently and stably. Take server power supplies as an example: the excellent thermal conductivity of potting adhesives can reduce internal temperatures by 10–15°C, effectively lowering the failure rate caused by overheating and extending the power supply’s service life by 2–3 years. Meanwhile, their insulating properties safeguard internal circuits and prevent issues such as short circuits.

Market Applications of Thermal Conductive Potting Adhesives

LED Lighting

When LED lamps emit light, approximately 20–30% of electrical energy is converted into heat. Accumulated heat raises the temperature of LED chips, reducing luminous efficiency and accelerating light decay. Thermal conductive potting adhesives rapidly transfer heat generated by LED chips to the housing, improving heat dissipation efficiency. In high-power LED street lamps, using thermal conductive potting adhesives ensures light flux maintenance remains above 90% after 5,000 hours, significantly enhancing lighting performance and lifespan compared to un-potted lamps. Additionally, the potting adhesive fills internal gaps in LED lamps, providing water and dust resistance, making them suitable for various harsh environments.、

Consumer Electronics

Key components in devices like smartphones and tablets, such as chips and batteries, generate heat during operation. High-performance thermal conductive potting adhesives evenly disperse heat from these components, preventing local overheating. For example, when potting a mobile phone’s mainboard, the adhesive can lower chip temperatures by 5–8°C, ensuring stable performance during prolonged use and reducing lag. It also enhances the device’s shock resistance, protecting internal precision circuits from vibration damage and improving product reliability.

Automotive Industry

Automotive Electronics

Electronic components in vehicles, such as engine control units (ECUs), on-board chargers, and headlights, face high-temperature challenges during operation. Thermal conductive potting adhesives provide efficient heat dissipation solutions for these components. For instance, using such adhesives in ECUs ensures stable operation in the engine compartment’s high-temperature environment (up to 120°C), avoiding control command errors caused by excessive heat and ensuring safe driving. Furthermore, the potting adhesive’s weather resistance adapts to vehicles used in different climatic conditions, preventing damage to electronic components from moisture, oxidation, and other factors.

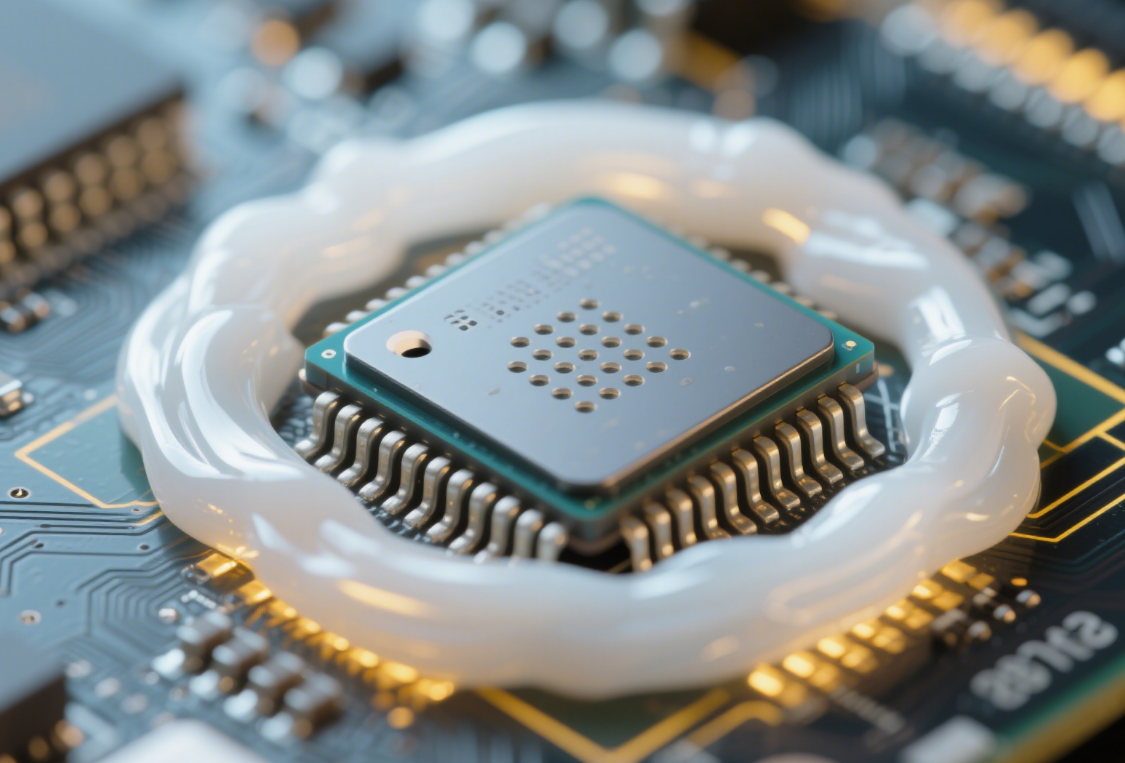

New Energy Vehicle Batteries

Heat management is critical for electric vehicle battery modules. Thermal conductive potting adhesives fill internal gaps in battery modules and quickly transfer heat generated by batteries to the cooling system. In practical applications, using these adhesives significantly improves the temperature consistency of battery modules, with temperature differences controlled within 3°C. This effectively avoids performance degradation and safety hazards caused by local overheating, extends battery lifespan, and enhances the driving range and safety of electric vehicles.

Industrial Manufacturing

Motors

During operation, motor windings generate significant heat, and excessively high temperatures reduce motor efficiency and may even burn out the motor. Thermal conductive potting adhesives transfer heat from motor windings to the housing, improving heat dissipation capacity. In some industrial high-power motors, using thermal conductive potting adhesives can lower operating temperatures by 15–20°C and increase motor efficiency by 3–5%, not only saving energy but also extending maintenance cycles and service life.

Sensors

Industrial sensors require stable performance in complex working environments. Thermal conductive potting adhesives help sensors dissipate heat quickly, ensuring measurement accuracy is not affected in high-temperature environments. Meanwhile, they provide protection, preventing dust, moisture, and other contaminants from eroding internal sensitive components of the sensors. For example, temperature sensors used in chemical production can operate stably in high-humidity and high-corrosion environments after applying thermal conductive potting adhesives, with measurement errors controlled within a minimal range, ensuring precise control of industrial production processes.