Knowledge about Acidic Adhesives for Silicone Bonding

2025/08/05

0

In the field of silicone bonding, acidic adhesives have become widely used bonding materials due to their unique properties. To make the expression more professional and clear, I will first highlight the advantages of acidic adhesives, then emphasize the importance of understanding their characteristics, so as to make the content more logical and attractive.

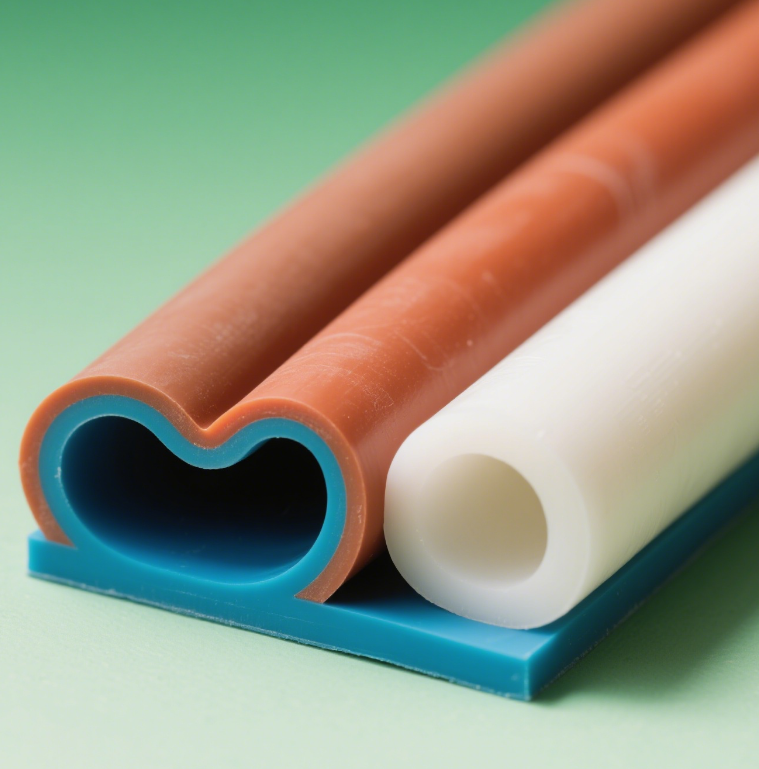

Acidic silicone sealant

In silicone bonding processes, acidic adhesives are preferred in many engineering and manufacturing scenarios because of their fast curing speed and strong initial bonding force. However, their complex chemical properties and specific application boundaries require users to have a thorough understanding of their performance parameters and application scenarios to give full play to their bonding efficiency.

Acidic adhesives, namely acidic silicone sealants, have polydimethylsiloxane as the main component. During the curing process, they release acetic acid gas, and this chemical reaction characteristic is the fundamental reason for their pungent odor.

In terms of bonding applicability, acidic adhesives have a certain bonding ability to some types of silicone. For some ordinary silicone products, after cleaning the surface, using acidic adhesives can form a bond with a certain strength. However, they also have obvious limitations. The acetic acid released by acidic adhesives is somewhat corrosive and may erode the silicone surface, affecting the performance and appearance of silicone products. This impact is more significant especially for some precision silicone products or those with high surface quality requirements. Moreover, for certain special types of silicone, such as addition-cured silicone, the components in acidic adhesives may hinder their curing, leading to bonding failure.

In terms of advantages, acidic adhesives cure relatively quickly, can form initial bonding in a short time, and improve work efficiency; their initial bonding force is good, making them suitable for some temporary fixing or low-requirement occasions.

However, the disadvantages cannot be ignored. In addition to the aforementioned corrosiveness and inapplicability to special silicones, the adhesive layer formed after acidic adhesives cure has relatively weak weather resistance and temperature resistance. In long-term environments with high temperature, humidity, or ultraviolet radiation, it is prone to aging, cracking, and other phenomena, affecting the durability of the bond.

In terms of applicable scenarios, acidic adhesives can be used for temporary fixing or simple bonding of ordinary silicone products with low requirements for bonding strength and durability, such as temporary installation of silicone sealing rings and simple splicing of small silicone ornaments. However, for food-grade silicone products, high-temperature resistant silicone components, and silicone products that need to be used outdoors for a long time, it is not recommended to use acidic adhesives for bonding.

When using acidic adhesives to bond silicone, the following points should be noted: First, thoroughly clean the silicone surface to remove oil, dust, and other impurities. Alcohol or special cleaning agents can be used for wiping, and ensure the surface is dry before applying the adhesive. Second, control the amount of adhesive when applying to avoid excessive overflow, which may affect the appearance and bonding effect. In addition, after applying the adhesive, wait for curing in a well-ventilated environment to avoid inhaling pungent gases. Finally, during the curing process, avoid external interference to the adhesive layer to ensure it can cure normally.

If there are high requirements for silicone bonding, special silicone adhesives can be selected, such as neutral sealants and instant adhesives. Neutral sealants do not release pungent gases during curing, have no corrosion to the silicone surface, and have good weather resistance and temperature resistance, making them suitable for bonding various silicone products. Instant adhesives have extremely fast bonding speed and can achieve high-strength bonding in a short time, but attention should be paid to controlling the dosage and operation methods when using them.

In conclusion, when choosing acidic adhesives for silicone bonding, factors such as bonding requirements and application scenarios should be comprehensively considered, and they should be used with caution to ensure the bonding effect and product quality.