High – Performance Sealing Rings: The Core Guarantee for Electronic Product Sealing

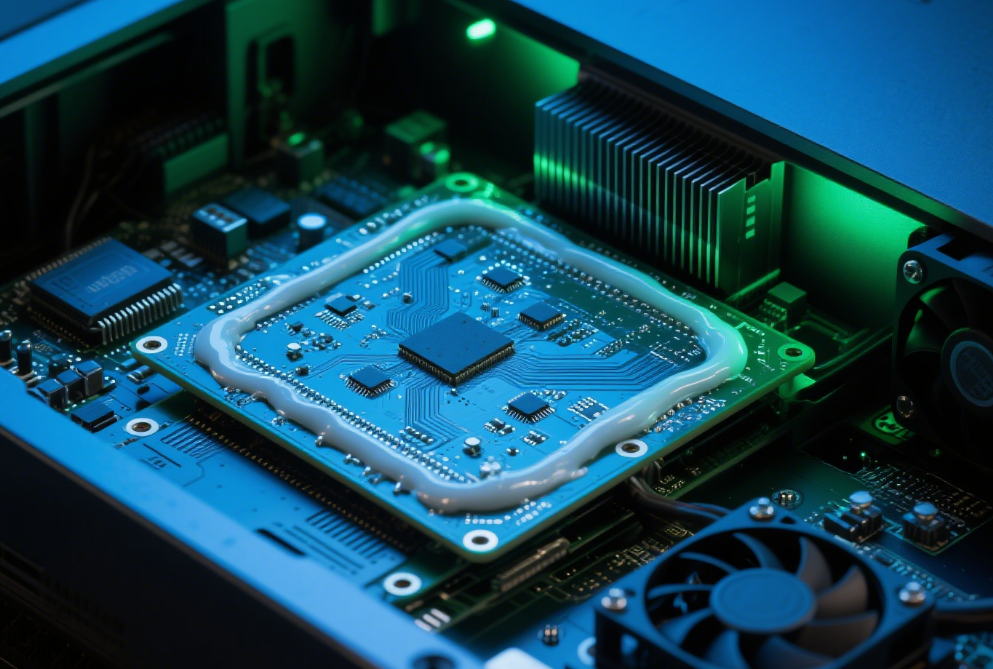

In the field of precision and miniaturized electronic products, sealing performance is a key factor in ensuring the stable operation of equipment and extending its service life. High – performance sealing rings, with their excellent material properties and structural design, have become the core choice for electronic product sealing solutions. They are widely used in various products such as smartphones, wearable devices, smart home terminals, and industrial control instruments.

High – performance sealing rings have a wide variety of sealing scenarios in electronic products. Take smartphones as an example. They need to provide dust – proof and water – proof sealing for the connection between the screen and the middle frame to prevent dust from entering the interior of the body during daily use and affecting the contact of components, and at the same time, prevent rainwater and splashed water from seeping into the motherboard and causing short circuits. At exposed interfaces such as charging ports and headphone jacks, the sealing rings need to achieve dynamic sealing through close fitting. They not only ensure the smoothness of plug – in and pull – out operations but also block the intrusion of liquids and impurities. In wearable devices such as smart watches, the sealing rings also need to adapt to the scenario of contact with human skin, having the characteristics of sweat corrosion resistance and anti – allergy. At the same time, they form reliable seals at parts such as strap connections and watch case closures to meet the protection needs of the devices in scenarios such as exercise and hand washing.

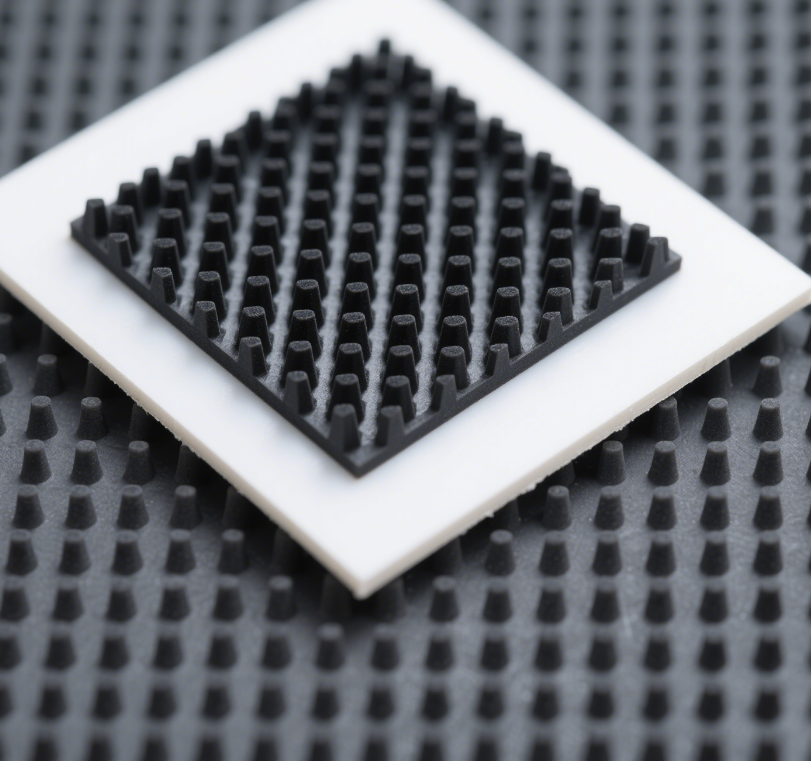

The core advantages of such sealing rings come from the dual upgrading of materials and processes. In terms of material selection, high – performance sealing rings mostly use special elastic materials such as hydrogenated nitrile butadiene rubber (HNBR), fluororubber (FKM), and silicone rubber (VMQ). Among them, fluororubber has extremely strong high and low – temperature resistance. It can maintain stable elasticity in the temperature range of – 20℃ to 200℃ and can adapt to the working state of electronic products in high – temperature environments, such as the area near the chip that runs for a long time. Silicone rubber has excellent insulation and biocompatibility, making it very suitable for the sealing needs of wearable devices. Meanwhile, these materials have been improved through special formulations, having excellent aging resistance and compression set resistance. Even under long – term stress, they can still maintain a good sealing effect, greatly extending the service life of the sealing rings.

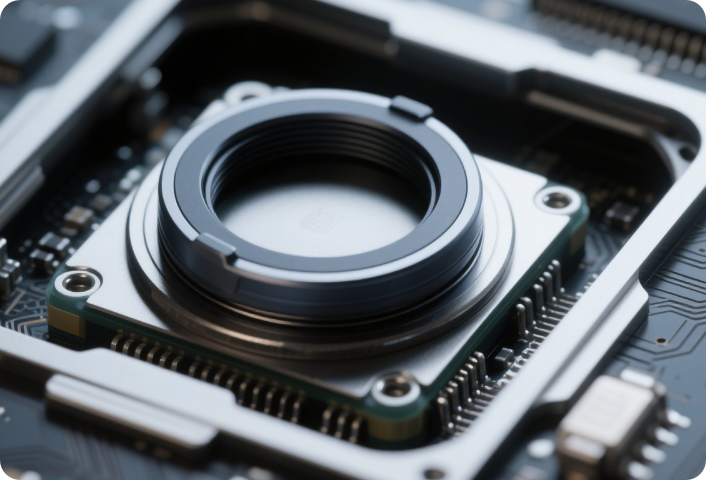

In terms of structural design, high – performance sealing rings have broken through the limitation of the traditional circular cross – section and adopted special – shaped structures according to the needs of different sealing parts. For example, the “L” – shaped cross – section sealing ring used in screen sealing can not only fit closely with the edge of the screen but also form a double sealing barrier with the middle frame. The lip – shaped structural sealing ring used in interface sealing realizes dynamic sealing through elastic deformation during plugging and unplugging, taking into account both sealing performance and ease of use. In addition, the surface of the sealing ring has been finely treated, which reduces the friction coefficient with the sealing surface, lowers the risk of damage during the assembly process, and improves the fitting accuracy of the sealing surface.

When selecting high – performance sealing rings, comprehensive consideration should be given to the specific use environment and sealing requirements of electronic products. If it is used for industrial testing equipment used outdoors, attention should be paid to the weather resistance and chemical corrosion resistance of the sealing ring, and fluororubber materials should be preferred. For consumer electronic products such as tablet computers, a balance should be found between sealing performance and lightweight, and silicone rubber materials may be a better choice. At the same time, the dimensional accuracy of the sealing ring is crucial, and it needs to match the processing accuracy of the sealing groove and the sealing surface to avoid sealing failure caused by dimensional deviation.

With the continuous upgrading of electronic product functions, the requirements for sealing performance are also constantly increasing. High – performance sealing rings provide reliable sealing guarantees for electronic products through material innovation, structural optimization, and process improvement. They not only reduce the risk of equipment failure caused by sealing problems but also lay the foundation for the application of electronic products in more complex environments. In the future, with the development of new material technologies, high – performance sealing rings will achieve further breakthroughs in sealing performance, durability, and adaptability, continuously ensuring the stable operation of electronic products.