Exploration and Development Prospects of Single-Walled Carbon Nanotubes in the Field of Transparent Conductive Films

2025/12/15

0

Against the backdrop of the rapid development of the modern electronic information industry and flexible optoelectronic technology, transparent conductive films, as core functional materials, are widely used in fields such as touch screens, display devices, solar cells, and smart windows. Traditional transparent conductive materials like indium tin oxide (ITO) possess excellent electrical conductivity and light transmittance; however, they have inherent drawbacks, including scarce resources, high brittleness, poor flexibility, and high costs. These limitations make it difficult for ITO to meet the demands of emerging fields such as flexible electronics and wearable devices. In this context, single-walled carbon nanotubes (SWCNTs), leveraging their unique one-dimensional nanostructure, outstanding electrical properties, excellent flexibility, and good chemical stability, have become highly promising alternative materials in the field of transparent conductive films, opening up a new direction for the development of transparent conductive technology.

Core Advantages of Single-Walled Carbon Nanotubes for Transparent Conductive Films

Single-walled carbon nanotubes are formed by rolling a single layer of graphene, with a diameter typically ranging from 0.4 to 2 nm. Their special electronic structure and micro-morphology endow transparent conductive films with numerous irreplaceable advantages.

In terms of electrical properties, high-quality SWCNTs exhibit extremely high carrier mobility and low scattering probability during electron transport. This enables transparent conductive films fabricated from SWCNTs to maintain excellent electrical conductivity even at low sheet resistance (usually required to be below 100 Ω/sq). Moreover, the stability of their conductive performance far surpasses that of traditional ITO materials, and they are less prone to resistance drift during long-term use or in complex environments.

In terms of optical properties, the atomic-level thickness of SWCNTs results in extremely low absorption of visible light. Meanwhile, their nanoscale diameter effectively avoids light scattering. Consequently, the light transmittance of SWCNT-based transparent conductive films can easily exceed 85%, and products manufactured using optimized processes can even achieve a light transmittance of over 90%. This fully meets the stringent light transmittance requirements of mainstream display devices and solar cells.

More importantly, SWCNTs possess excellent flexibility, with an elastic modulus and tensile strength comparable to those of carbon fibers. When fabricated into transparent conductive films, their electrical conductivity and light transmittance show almost no degradation even after tens of thousands of bending, folding, or stretching cycles. This characteristic makes them an ideal choice for flexible electronic devices, perfectly addressing the issue of traditional ITO films, which are prone to fracture and performance failure in flexible applications.

Additionally, SWCNTs exhibit good chemical stability. They are resistant to oxidation or corrosion in acidic/alkaline environments and high-temperature/high-humidity conditions, which can effectively extend the service life of transparent conductive films. At the same time, their raw materials are relatively abundant, and their preparation process is more environmentally friendly than that of ITO materials, aligning with the industrial trend of green and sustainable development.

Main Application Fields of SWCNT-Based Transparent Conductive Films

Flexible Displays and Touch Screens

With the rise of products such as flexible smartphones, foldable tablets, and flexible wearable devices (e.g., smart bracelets and smart watches), there are extremely high requirements for the flexibility and bending stability of transparent conductive films. SWCNT-based transparent conductive films, with their excellent flexibility and conductive stability, have become one of the core materials in this field.

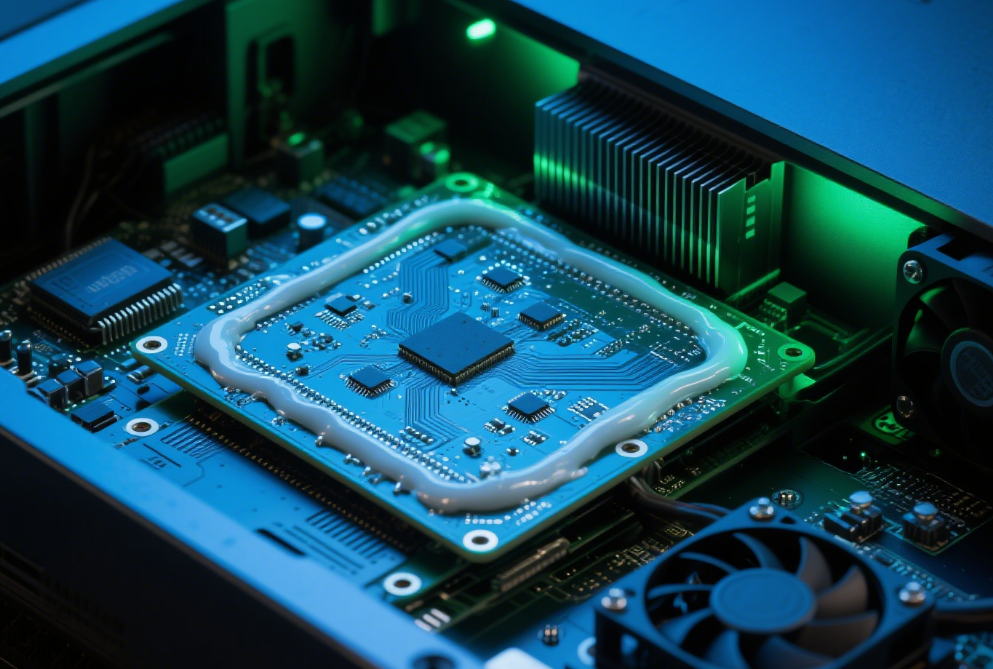

In flexible touch screens, SWCNT films can be directly used as conductive electrode layers to replace traditional ITO electrodes. They not only enable precise touch response but also withstand repeated bending without affecting touch performance. For instance, in flexible AMOLED displays developed by some manufacturers, SWCNT-based transparent conductive films are used as top electrodes, allowing the displays to achieve 180° folding. After 100,000 bending tests, the sheet resistance change rate of the electrodes is less than 5%, which is far superior to the performance of ITO films. Meanwhile, the high light transmittance of SWCNT films ensures high color reproduction and clear images of the displays, providing users with an excellent visual experience.

Solar Cells

In solar cells (especially thin-film solar cells such as organic solar cells and perovskite solar cells), transparent conductive films serve as front electrodes, requiring both high light transmittance and low resistance. This is to maximize the amount of sunlight entering the cell and effectively collect the photo-generated carriers produced. SWCNT-based transparent conductive films demonstrate significant advantages in this field:

On one hand, their high light transmittance reduces light reflection and absorption losses, improving the light absorption efficiency of solar cells. On the other hand, their low sheet resistance reduces energy loss during carrier transport, enhancing the fill factor and open-circuit voltage of the cells. Compared with traditional ITO electrodes, SWCNT electrodes also have better weather resistance. During long-term outdoor use, they are less likely to undergo performance degradation due to water vapor or ultraviolet radiation, thereby extending the service life of solar cells.

Currently, research teams have fabricated perovskite solar cells based on SWCNT-based transparent conductive films, achieving a photoelectric conversion efficiency of over 23%. After 1,000 hours of stability testing, the efficiency retention rate exceeds 90%, demonstrating promising prospects for industrial application.

Smart Windows and Transparent Heating

Smart windows (e.g., electrochromic smart windows and photochromic smart windows) are important components of energy-efficient buildings and smart cockpits. They require transparent conductive films as driving electrodes to achieve precise regulation of window light transmittance. SWCNT-based transparent conductive films not only meet the requirements for light transmittance and conductivity of smart windows but also form good interfacial contact with electrochromic or photochromic materials, ensuring stable driving voltage and fast response speed.

For example, in electrochromic smart windows, SWCNT films act as upper and lower electrodes. When a certain voltage is applied, the intermediate electrochromic layer undergoes a redox reaction, changing its color depth. This adjusts the intensity of sunlight entering the room, achieving the goal of energy conservation and consumption reduction.

In addition, SWCNT-based transparent conductive films can be applied in the field of transparent heating, such as defogging films for car rearview mirrors, anti-icing films for aircraft windows, and heating films for smart glass. Their excellent conductivity allows the film to heat up quickly and uniformly when energized, while their high light transmittance does not affect visibility. Taking car rearview mirror defogging films as an example, SWCNT-based heating films can heat up to over 50°C within 30 seconds after being energized, quickly removing fog and frost from the mirror surface. During the heating process, the film shows no obvious thermal deformation and has a long service life.

Other Emerging Application Fields

Beyond the aforementioned main fields, SWCNT-based transparent conductive films also show broad application potential in emerging areas such as sensors, transparent electromagnetic shielding, and quantum dot displays.

- In the field of sensors: Utilizing the high conductivity and large specific surface area of SWCNTs, transparent gas sensors, humidity sensors, and biosensors can be fabricated. For example, transparent humidity sensors can be integrated into smart glass or display panels to monitor changes in environmental humidity in real time without affecting the light transmittance of the devices.

- In the field of transparent electromagnetic shielding: SWCNT films can effectively shield electromagnetic radiation while maintaining good light transmittance. They are suitable for scenarios such as aerospace and medical equipment, where both electromagnetic shielding and light transmittance are required.

- In the field of quantum dot displays: SWCNT-based transparent conductive films can serve as electrodes for quantum dot light-emitting layers. Their excellent conductivity and interfacial compatibility can improve the luminous efficiency and stability of quantum dots, promoting the industrialization of quantum dot display technology.

Challenges and Future Development Directions of SWCNT-Based Transparent Conductive Films

Although SWCNT-based transparent conductive films have many advantages, they still face several challenges in industrial application.

First, the preparation cost of SWCNTs is relatively high. Particularly for high-quality, high-purity SWCNTs, the synthesis process (e.g., chemical vapor deposition, arc discharge) is complex and the yield is low. This makes it difficult for the production cost of SWCNT-based transparent conductive films to compete with that of traditional ITO films, limiting their application in mid-to-low-end product fields.

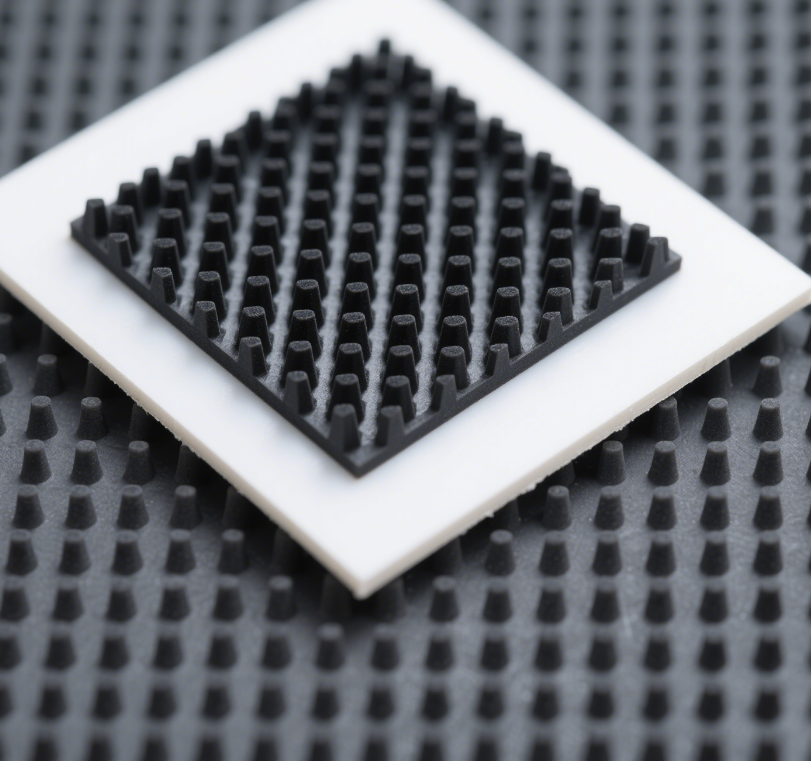

Second, SWCNTs tend to agglomerate during the dispersion process. Agglomerated carbon nanotubes reduce the light transmittance and conductivity of the film. Although methods such as adding dispersants and using ultrasonic dispersion can improve dispersion efficiency, it remains difficult to achieve complete monodispersion of SWCNTs, which affects the uniformity of film performance.

Third, the interfacial adhesion between SWCNTs and substrate materials (e.g., glass, flexible polymer substrates) needs to be improved. During long-term use or bending, the film is prone to peeling off, which affects the reliability of the product.

To address these challenges, the future development directions of SWCNT-based transparent conductive films will focus on the following aspects:

- Optimizing the preparation process of SWCNTs: Developing low-cost, large-scale synthesis technologies—such as improving the catalyst system of chemical vapor deposition and optimizing reaction conditions—to increase the yield and purity of SWCNTs and reduce production costs.

- Developing efficient dispersion technologies: Designing new dispersants and adopting composite dispersion methods (e.g., electrostatic dispersion, mechanical grinding dispersion) to achieve uniform dispersion of SWCNTs, reduce agglomeration, and improve the uniformity of film performance.

- Improving film preparation processes: Adopting low-cost, large-area preparation technologies (e.g., vacuum filtration, spray coating, printing). Meanwhile, enhancing the interfacial adhesion between SWCNTs and substrates through surface modification and the introduction of binders to improve film adhesion and stability.

- Promoting the compounding of SWCNTs with other materials: Combining SWCNTs with materials such as graphene and metal nanowires to create a synergistic effect, further improving the conductivity, light transmittance, and flexibility of transparent conductive films and expanding their application scenarios.

Dongguan Yusheng Technology Co., Ltd. is a professional enterprise engaged in the R&D of new materials. For inquiries regarding transparent conductive films, please contact us via email: zhengzhen@nqrubber.com