Comprehensive Analysis of the Core Application Scenarios of Thermal Conductive Sealant

2026/01/05

0

I. Core Application Logic: The Key Path to Breaking the “Thermal Bottleneck”

The rising integration of microelectronic devices (e.g., 3D packaging, Chiplet) and surging power consumption (the power consumption of AMD MI300X chip exceeds 1000W) have led to heat flux density exceeding 500W/cm², with over half of equipment failures caused by overheating. Thermal conductive materials address this challenge through three core functions:

- Near-junction Heat Conduction: Directly contacts the heat-generating core of the chip to reduce junction temperature (e.g., diamond substrate lowers junction temperature by 30-50℃).

- Interface Thermal Resistance Bridging: Fills the microscopic gaps between devices and heat sinks (actual contact area is only 10%), replacing air (thermal conductivity: 0.025W/m·K).

- Multi-dimensional Heat Diffusion: Adapts to thermal management needs in special scenarios such as flexible and micro-nano applications.

II. Mainstream Material Types and Scenario Implementation

(1) Chip Core Layer: “Close-proximity Protection” with Ultra-high Thermal Conductivity Materials

Diamond-based Materials

- Performance Advantages: Thermal conductivity reaches 2000-2200W/m·K (more than 5 times that of copper), making it an ideal substrate for third-generation semiconductors.

- Technological Breakthroughs: The Ningbo Institute of Materials Technology & Engineering, Chinese Academy of Sciences, has prepared 4-inch ultra-thin diamond films with a warpage ≤10μm, enabling “self-adhesive” bonding of chips.

- Application Directions: AI chips, radio frequency (RF) devices; future development targets large-size demands of 6 inches and above.

Liquid Metals

- Performance Advantages: Thermal conductivity >30W/m·K, with interface thermal resistance 80% lower than that of thermal grease.

- Typical Applications: Gallium-based TIM is adopted in Intel Core i9 and AMD Ryzen 7000 series processors, reducing core temperature by 5-10℃; it serves as a core component in the cooling system of Sony PS5.

(2) Packaging and Substrate Layer: “Connecting Link” with Insulating and Thermal Conductive Properties

Ceramic-based Materials

- Silicon Nitride (Si₃N₄): Thermal conductivity of 90W/m·K; its AMB substrate is applied in the SiC power module of Tesla Model 3, improving driving range by 12%.

- Aluminum Nitride (AlN): Thermal conductivity of 100-200W/m·K, suitable for high-frequency insulation requirements of 5G base station RF modules.

Low-dielectric & High-thermal Conductivity Polymers

- The liquid crystal polymer ST38PB, developed by the Shanghai Institute of Organic Chemistry, Chinese Academy of Sciences, has an in-plane thermal conductivity of 0.62W/m·K (3.4 times that of the original material) and a dielectric constant of only 2.4 at 10GHz.

- Application Scenarios: High-frequency PCB, chip insulating and heat-dissipating layers, resolving the contradiction between signal crosstalk and heat dissipation.

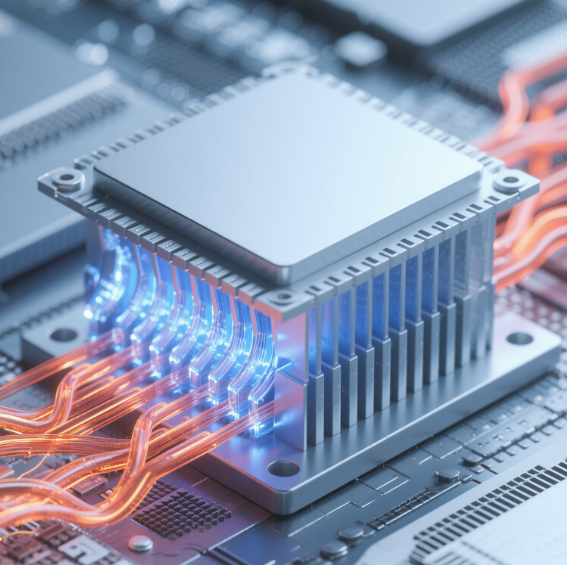

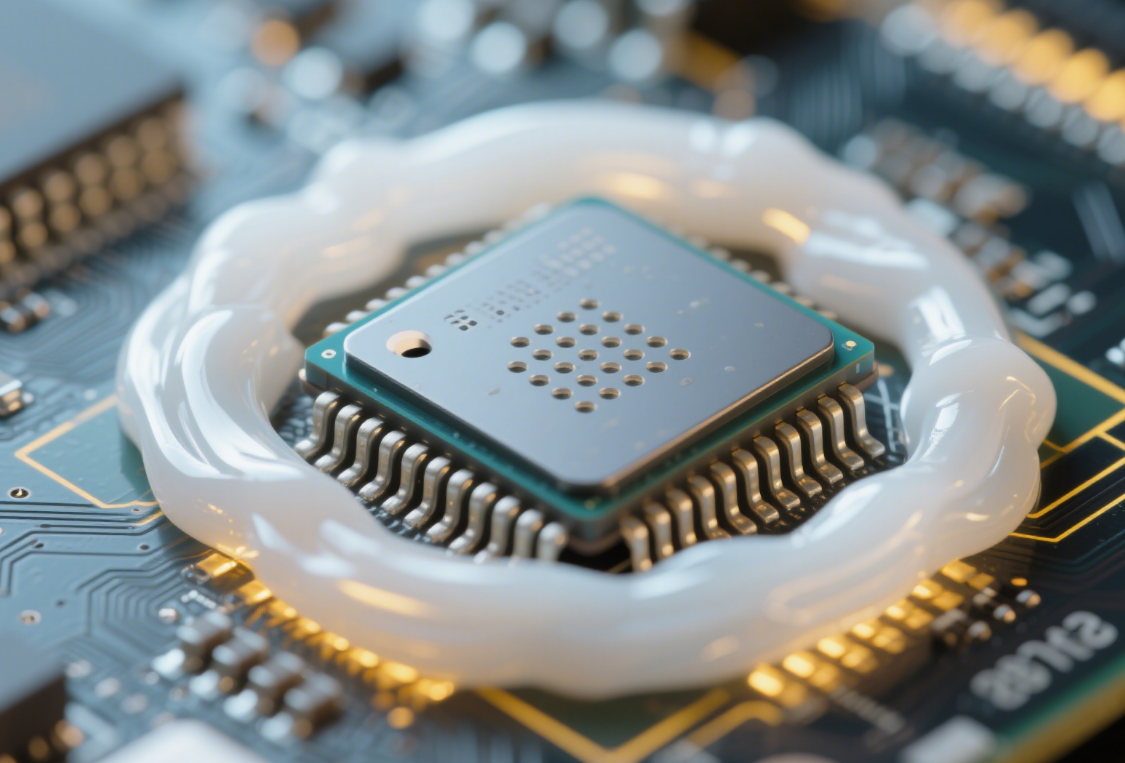

(3) Interface Connection Layer: “Gap Filling” with TIM Materials

Thermal Conductive Silicone Gel

- Features: Thermal conductivity up to 12W/m·K; maintains flexibility after curing, suitable for vibration environments.

- Applications: 400G/800G optical modules, vehicle-mounted IGBT modules, battery management systems (BMS).

Phase Change Materials (PCM)

- Principle: Melts and absorbs heat at 50-100℃, suppressing short-term pulse thermal shock.

- Implementation: Power amplifiers of 5G base stations, lidars, preventing performance degradation caused by sudden temperature rise.

(4) Micro-nano and Flexible Scenarios: “Precise Adaptation” with New Materials

Two-dimensional Transition Metal Carbides (MoS₂, WS₂)

- Performance: Thermal conductivity of 200-300W/m·K, 5-8 times that of silicon-based materials.

- Innovative Applications:

- MEMS sensors: MoS₂/TiO₂ heterojunction increases sensitivity by 3 times.

- Wearable devices: Liquid metal-two-dimensional material composite films maintain a thermal conductivity of 287W/m·K even under 200% stretching.

Diamond Composite Materials

- Polymer-based: After filling with surface-modified diamond, thermal conductivity increases by 5-10 times, applied in TIM of mobile phone chips.

- Metal-based: Diamond/copper composite materials have a thermal conductivity of 600W/m·K, suitable for aerospace electronic equipment.