Application of Thermal Conductive and Waterproof Adhesive in the Electronic Field

2025/07/23

0

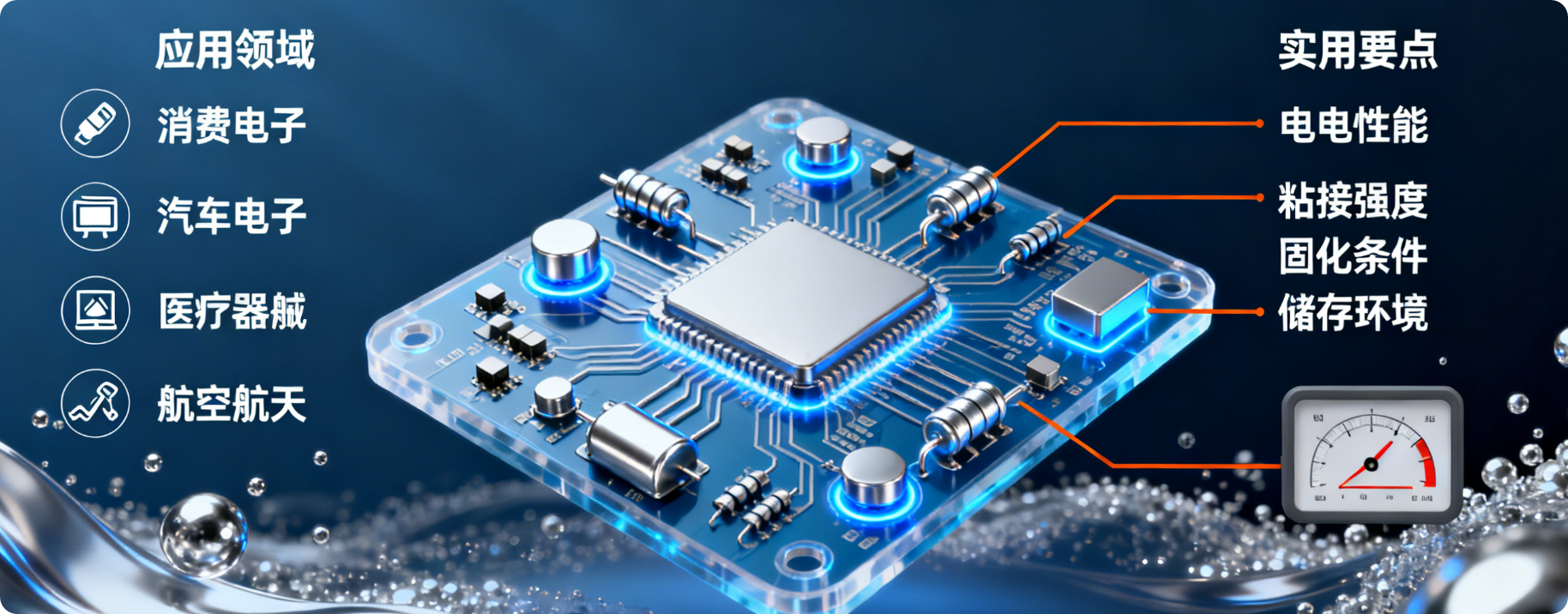

Against the trend of electronic products developing towards miniaturization and high power, “heat dissipation” and “moisture proofing” have become two core requirements for ensuring the stable operation of devices. Thermal conductive and waterproof adhesives, with their dual properties of “thermal conductivity” and “waterproof sealing”, have gradually become key functional materials inside electronic devices, and their application scenarios have covered multiple fields such as consumer electronics, industrial electronics, and automotive electronics.

Thermal Conductive and Waterproof Adhesive

In the field of consumer electronics, the application of thermal conductive and waterproof adhesives is directly related to users’ daily use experience. Take smart phones as an example. Their internal core components such as SOC chips and 5G radio frequency modules generate a lot of heat when running under high load (such as playing games and video rendering). However, the internal space of the phone body is compact. Traditional heat dissipation stickers can only solve the problem of thermal conductivity but cannot block water vapor. At this time, thermal conductive and waterproof adhesives will be used to bond the chip to the metal middle frame and graphite heat sink. It can quickly transfer the chip heat to the heat dissipation structure through its own thermal conduction path, and at the same time form a sealing layer around the chip to block the contact between external water vapor (such as rainwater and sweat when seeping into the phone body) and the chip, avoiding short circuits or corrosion. In wearable devices such as smart watches and Bluetooth headsets, the role of thermal conductive and waterproof adhesives is more prominent. These devices are in long-term contact with human sweat (containing salt) and external moisture. The packaging of their sensor modules (such as heart rate sensors and acceleration sensors) requires thermal conductive and waterproof adhesives. They not only conduct the trace heat generated by the sensors during operation through thermal conductivity (to avoid temperature drift affecting detection accuracy) but also prevent sweat from seeping into the modules through waterproof sealing, ensuring the stability of data collection.

The industrial electronics field has higher requirements for the reliability of equipment, and thermal conductive and waterproof adhesives are often used for electronic components working outdoors or in humid environments. For example, outdoor meteorological sensors. Their internal circuit modules need to withstand the influence of rain, snow, condensation and other environments for a long time. At the same time, the measurement chips of the sensors (such as temperature and humidity chips) themselves will generate heat due to working current. If heat accumulates, it will lead to measurement deviations. At this time, thermal conductive and waterproof adhesives will be used for the sealing and bonding of the circuit module and the metal shell. On the one hand, it can conduct the chip heat to the shell for dissipation to ensure measurement accuracy. On the other hand, the elastic sealing layer formed by the colloid can resist a waterproof level of IP67 or higher. Even if the sensor is in a short-term water immersion or heavy rain environment, the internal circuit can work normally. In addition, thermal conductive and waterproof adhesives can also play a role at the interfaces of industrial control equipment (such as the terminals of PLC modules). They not only seal the interface gaps to prevent dust and water vapor from entering but also reduce the local temperature rise at the interface caused by current contact through thermal conductivity, avoiding interface oxidation and aging.

In the field of automotive electronics, the application of thermal conductive and waterproof adhesives needs to adapt to more complex working conditions. Vehicle-mounted electronic devices not only have to face the impact of condensation water in the car (such as water vapor near the air-conditioning vents) and rain and snow outside the car but also bear the high temperature of the engine compartment (the temperature in some areas can reach more than 120℃) and the vibration of the car body. Take the vehicle-mounted millimeter-wave radar as an example. It is installed inside the front bumper and must resist rainwater and high-pressure water flow during car washing, and also conduct out the heat generated by the radar chip during operation (the chip power consumption is high when the radar emits electromagnetic waves). Thermal conductive and waterproof adhesives will be used to bond the radar antenna to the metal base. The colloid must have temperature resistance from -40℃ to 150℃, maintain stable thermal conductivity at high temperatures, and offset the stress caused by car body vibration through the elastic sealing structure to avoid gaps between the antenna and the base that lead to water vapor infiltration. In the backlight module of the vehicle-mounted central control screen, thermal conductive and waterproof adhesives are used to fix the LED lamp beads to the heat-dissipating aluminum substrate. They not only conduct the heat of the lamp beads to prevent the screen from overheating and dimming locally but also seal the gaps between the lamp beads and the substrate to avoid oxidation of the lamp bead solder joints caused by water vapor in the car.

Compared with the traditional combination scheme of “thermal conductive materials + waterproof seals”, the core advantage of thermal conductive and waterproof adhesives lies in “solving problems in an integrated way”. It can reduce assembly steps (no need to install gaskets and thermal conductive stickers separately), and at the same time, through the close fit between the colloid and electronic components, avoid the decrease in thermal conductivity efficiency or seal failure caused by assembly gaps. In the future, as electronic products have higher requirements for environmental adaptability and service life, thermal conductive and waterproof adhesives will also be upgraded in the directions of “high thermal conductivity”, “low volatility”, and “rapid curing”, further expanding their applications in emerging electronic devices such as drones and new energy charging piles.