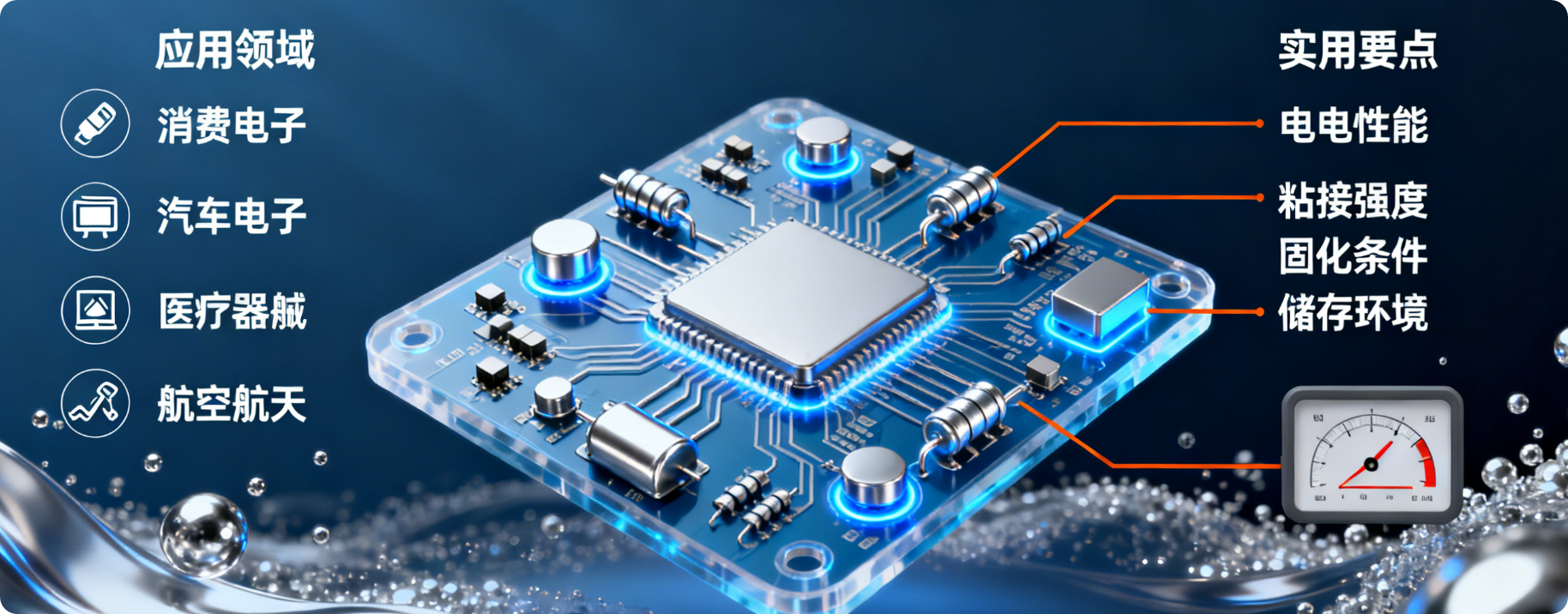

Application of Conformal Coating on Circuit Boards

2025/08/06

0

In the complex world of electronic devices, circuit boards serve as the core, enabling the smooth operation of various functions. However, they are vulnerable to numerous environmental threats. Conformal coating emerges as a crucial solution to protect these vital components.

Conformal Coating on Circuit Boards

Conformal coating is a thin protective layer applied to the surface of circuit boards. Its primary function is to shield the circuit boards from a variety of environmental factors. It can effectively resist moisture, preventing water vapor from penetrating into the circuit board and causing short circuits or corrosion of components. Dust and other particulate matter are also blocked by the coating, avoiding the accumulation that may affect the performance of the circuit board. In addition, conformal coating provides a barrier against chemical substances such as oils, solvents, and corrosive gases, which could otherwise damage the circuit board’s components and conductors. It also helps to mitigate the impact of temperature changes, reducing the stress on the circuit board caused by thermal expansion and contraction.

The application scenarios of conformal coating on circuit boards are widespread. In automotive electronics, circuit boards are exposed to constant vibrations, wide temperature ranges, and oil stains. Conformal coating forms a barrier, preventing these factors from damaging the boards, ensuring the stable operation of vehicle systems such as engine control units, infotainment systems, and safety modules.

In the aerospace field, the environment is extremely harsh. Circuit boards used in aircraft and spacecraft have to withstand extreme temperatures, high levels of radiation, and vacuum conditions. Conformal coating plays a critical role here, providing reliable protection to ensure the normal functioning of navigation systems, communication equipment, and other key electronic components.

Consumer electronics, such as smartphones, tablets, and home appliances, also benefit from conformal coating. It helps to enhance the durability and reliability of these devices, making them more resistant to daily wear and tear, moisture, and dust, thereby extending their service life.

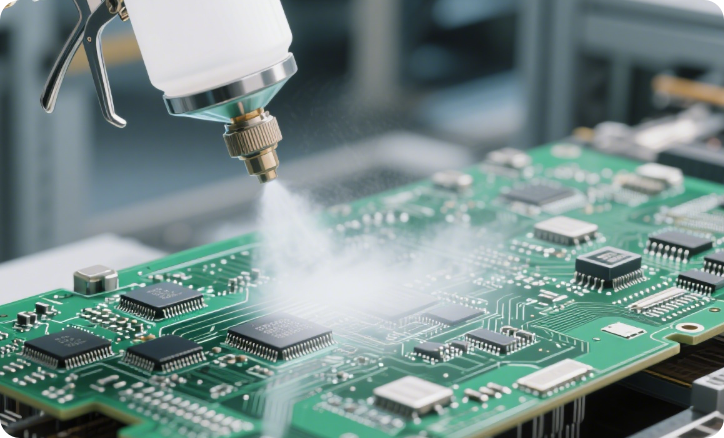

There are several common application methods for conformal coating. Brushing is a simple and flexible method, suitable for small-area coating or repair work. It allows for precise application but may be less efficient for large-scale production. Spraying is widely used in mass production. It can cover large areas quickly and evenly, ensuring consistent coating thickness. Dipping involves immersing the circuit board in the coating material, which is suitable for complex-shaped circuit boards and can achieve complete coverage, including hard-to-reach areas. However, it requires careful control of the withdrawal speed to avoid excessive coating.

The advantages of using conformal coating on circuit boards are significant. It greatly improves the reliability of the circuit boards, reducing the risk of failures caused by environmental factors. This, in turn, extends the service life of the electronic devices, reducing maintenance costs and downtime. Moreover, conformal coating helps to maintain the performance of the circuit board under various harsh conditions, ensuring the stability and functionality of the entire electronic system.

In conclusion, conformal coating is an indispensable protective measure in the manufacturing and application of circuit boards. Its diverse application methods and wide range of protective effects make it a key factor in ensuring the reliable operation of electronic devices in various industries.