Application Guide for Waterproof Adhesive of Robot Vacuums

2025/10/15

0

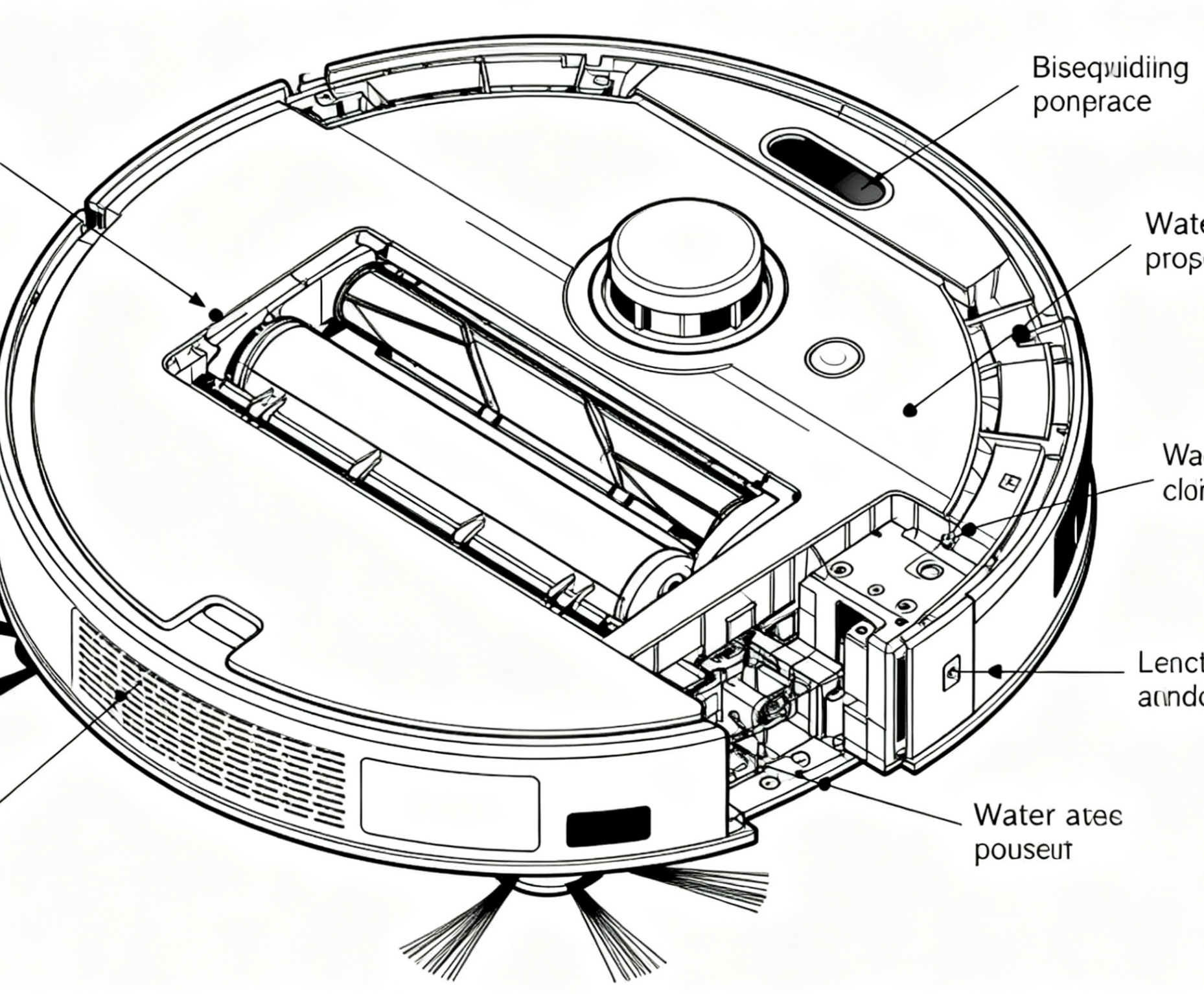

The core function of the waterproof adhesive for robot vacuums is to seal the key parts of the device, prevent sewage and water stains generated during the cleaning process from seeping into the interior, thereby protecting electronic components and mechanical structures and reducing the probability of equipment failure.

I. Core Application Scenarios

The application of waterproof adhesive focuses on the parts of the robot vacuum that are in direct contact with water or humid environments, which can be specifically divided into the following three categories:

Waterproof Adhesive of Robot Vacuums

(I) Water Tank and Water Circuit System

- Core Function: Prevent leakage of clean water in the water tank or sewage generated after cleaning. This is the most important application scenario of waterproof adhesive and directly determines the sealing performance of the water tank.

- Key Sealing Points: The joint of the upper and lower covers of the water tank, and the connection between the water outlet of the water tank and the connecting pipe.

(II) Electronic Component Protection

- Core Function: Form a moisture-proof protective layer for electronic components to prevent short circuits of components caused by ground moisture or a small amount of splashing water, and ensure the stable operation of the equipment circuit.

- Key Sealing Points: The edge of the main board, the battery interface, and the circuit board edges of various sensors (such as cliff sensors and collision sensors).

(III) Sealing of Moving Parts

- Core Function: Prevent the liquid formed by the mixture of ground sewage and dust from entering the interior of moving parts, and extend the service life of components such as motors.

- Key Sealing Points: The gap between the roller brush motor bearing and the machine body, the gap between the side brush motor bearing and the machine body, and the installation position of the universal wheel.

II. Key Application Principles

The correct use of waterproof adhesive must follow the following 3 principles; non-compliance may affect the waterproof effect or hinder subsequent equipment maintenance:

(I) Adhesive Type Adaptation

Different application parts need to be matched with corresponding types of waterproof adhesive to avoid seal failure or component corrosion due to incorrect adhesive type:

- Water Tank Sealing: Priority is given to silicone adhesive with good flexibility, which adapts to the slight deformation of water tank components and ensures long-term sealing.

- Electronic Component Protection: Epoxy adhesive with strong insulation is selected to ensure circuit insulation while preventing moisture and avoid the risk of short circuits.

- Sealing of Moving Parts: Nitrile rubber adhesive with wear resistance and anti-aging properties can be selected to adapt to the frequent friction scenarios of moving parts.

(II) Standardized Operation

- Surface Cleaning: Before applying the adhesive, the surface to be sealed must be thoroughly cleaned to remove impurities such as dust and oil (anhydrous ethanol can be used for wiping); otherwise, the adhesion of the adhesive layer will be affected.

- Adhesive Coating Thickness: The thickness of the adhesive coating must be uniform, usually controlled at 0.5-1mm; too thin a coating may lead to seal gaps, while too thick a coating may block component interfaces or hinder the normal assembly of components.

- Curing Waiting: After applying the adhesive, sufficient curing time must be allowed according to the requirements of the adhesive type to avoid damaging the adhesive layer by assembling components before curing.

(III) Reserved Maintenance Space

Avoid using permanent waterproof adhesive on parts that need frequent disassembly; priority should be given to sealing materials that facilitate subsequent maintenance:

- Parts that need regular opening (such as battery compartment covers): Select peelable sealant, which can be completely peeled off during disassembly without damaging the parts.

- Semi-fixed parts (such as the installation position of the side brush motor): Waterproof foam can be used together to balance the sealing effect and disassembly convenience.