Analysis of the Application of Silicone Encapsulating Adhesive in the Electronic and Electrical Field

2025/06/05

0

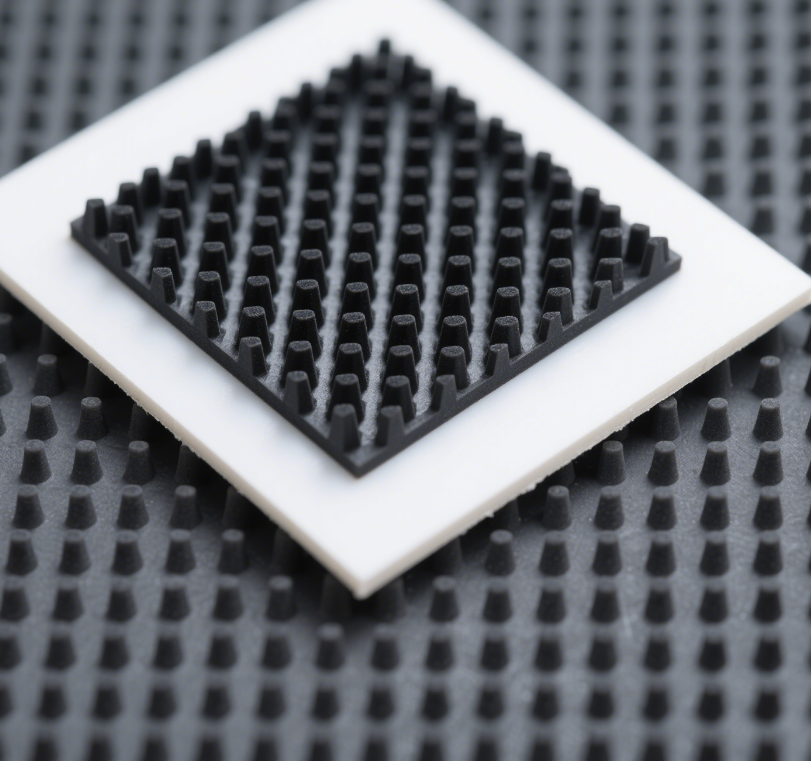

n the electronic and electrical industry, ensuring the stable and reliable operation of equipment is of utmost importance. As a key material, silicone encapsulating adhesive plays a vital role in the sealing and fixing of electrical and electronic components. Its ultimate goal is to prevent vibration and isolate circuits from various adverse environmental factors, thereby significantly enhancing the operational reliability of electronic products.

Properties and Advantages of Silicone Encapsulating Adhesive

Silicone encapsulating adhesive boasts exceptional performance, enabling it to adapt to various harsh environments. It features excellent temperature resistance, maintaining stable performance across a wide temperature range. Whether in high-temperature or low-temperature conditions, it can effectively protect electronic components. Meanwhile, its superior insulation properties can reliably isolate circuits, preventing issues such as short circuits. Additionally, it offers good flexibility and adhesion, allowing it to closely conform to the surfaces of electronic components and form a reliable protective layer.

Silicone encapsulating adhesive boasts exceptional performance, enabling it to adapt to various harsh environments. It features excellent temperature resistance, maintaining stable performance across a wide temperature range. Whether in high-temperature or low-temperature conditions, it can effectively protect electronic components. Meanwhile, its superior insulation properties can reliably isolate circuits, preventing issues such as short circuits. Additionally, it offers good flexibility and adhesion, allowing it to closely conform to the surfaces of electronic components and form a reliable protective layer.

Specific Applications in Different Scenarios

Marine Electronic Systems

Ships sail at sea for long periods, exposing their electronic systems to harsh environments such as moisture, condensation, and salt spray. Moisture can cause circuit dampness and trigger short-circuit failures; condensation can form water droplets on circuit boards, affecting normal circuit operation; and salt spray is corrosive and can damage circuits. To address these challenges, silicone encapsulating adhesive is used to seal circuit boards. By uniformly coating the adhesive on the surface of the circuit board, a dense protective film is formed, preventing moisture, condensation, and salt spray from coming into contact with the circuits, thus ensuring the stable operation of marine electronic systems.

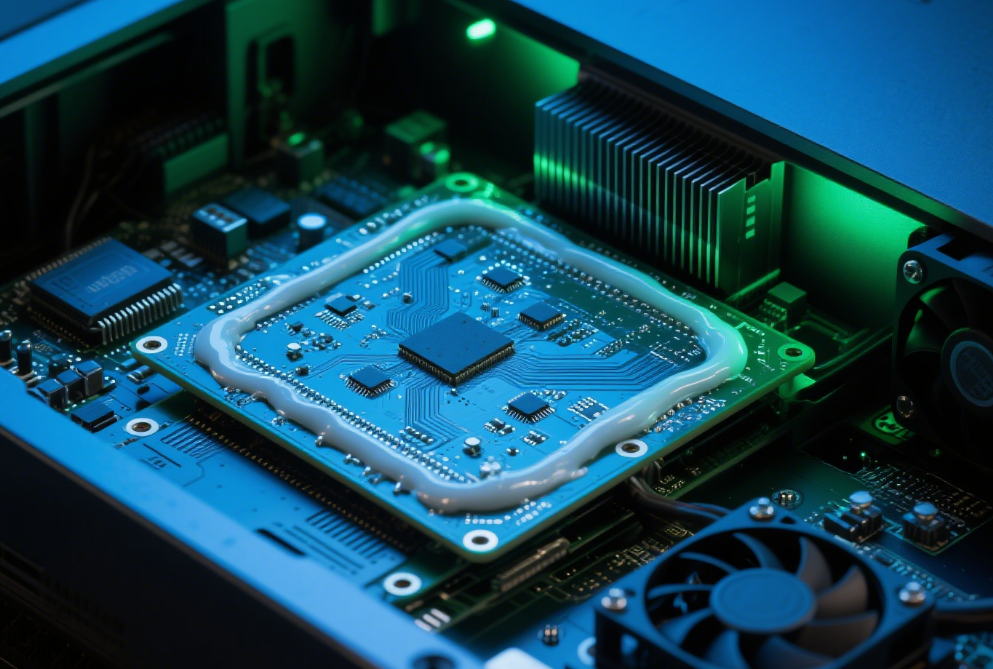

Subsea Electronic Equipment

Electronic equipment operating underwater faces even more severe conditions. In addition to moisture, they must withstand the pressure of seawater and long-term corrosion from immersion. All components such as transformers and chokes require sealing, coating, encapsulation, or end-sealing treatments. Silicone encapsulating adhesive can meet these requirements: it forms a robust protective layer on component surfaces, not only isolating seawater and preventing corrosion but also withstanding certain pressures. This enhances the equipment’s protection capabilities and ensures the normal operation of subsea electronic equipment in complex marine environments.

Aircraft and Aerospace Electronic Equipment

Marine Electronic Systems

Aircraft and aerospace electronic equipment are subjected to strong vibrations and impacts during operation, placing high demands on their vibration resistance. Silicone encapsulating adhesive can be used to fix and seal the components of these electronic devices. By firmly securing the components to the circuit board, it reduces the impact of vibrations on the components, thereby improving the equipment’s vibration resistance. At the same time, the adhesive isolates external adverse environments such as dust and moisture, ensuring the reliable operation of electronic equipment in harsh high-altitude environments.

Application Effects and Significance

The use of silicone encapsulating adhesive has significantly improved the reliability of electronic products in various harsh environments. In applications across marine, subsea, aircraft, and aerospace fields, it has effectively reduced equipment failures caused by environmental factors, lowered maintenance costs, and extended equipment service life. With the continuous development of the electronic and electrical industry and the increasing demand for equipment reliability, silicone encapsulating adhesive will be widely adopted in more fields due to its excellent performance, providing a strong guarantee for the stable operation of electronic and electrical equipment.

The use of silicone encapsulating adhesive has significantly improved the reliability of electronic products in various harsh environments. In applications across marine, subsea, aircraft, and aerospace fields, it has effectively reduced equipment failures caused by environmental factors, lowered maintenance costs, and extended equipment service life. With the continuous development of the electronic and electrical industry and the increasing demand for equipment reliability, silicone encapsulating adhesive will be widely adopted in more fields due to its excellent performance, providing a strong guarantee for the stable operation of electronic and electrical equipment.