Core functions: Protect fiber surface, enhance mechanical strength, improve weather resistance.

Key technical requirements:

Adhesive Technology Requirements in the Field of Optical Communication

- Optical performance: Low transmission loss, high light transmittance (matching fiber operating wavelength)

- Environmental resistance: UV radiation resistance (preventing long-term outdoor aging), hydrolysis resistance (for humid environments)

- Mechanical properties: Flexible protective layer after curing, impact and bending resistance

Core functions: Provide waterproof sealing, resist corrosive media, adapt to extreme temperatures.

Key technical requirements:

Adhesive Technology Requirements in the Field of Optical Communication

- Protective performance: Excellent waterproofing (preventing moisture penetration), chemical corrosion resistance (resisting soil/seawater erosion)

- Temperature adaptability: Cold resistance (no brittle fracture at low temperatures), heat resistance (no flowing at high temperatures)

- Adhesion performance: High-strength adhesion to both metals (strength members) and plastics (sheath materials)

Core functions: Precisely fix optical elements, ensure optical path stability.

Key technical requirements:

Adhesive Technology Requirements in the Field of Optical Communication

- Optical performance: High transparency, low absorption in visible and infrared bands

- Curing characteristics: Very low shrinkage (≤0.5%) to prevent optical element deformation

- Stability: Dimensionally stable after curing, no creep during long-term use

Core functions: High-precision bonding of fiber arrays with V-grooves.

Key technical requirements:

- Shrinkage: Low curing shrinkage (≤0.3%), maintaining fiber positioning accuracy (≤1μm deviation)

- Temperature adaptability: Wide temperature range (-40℃~85℃, up to ≥125℃ for high-end applications)

- Mechanical performance: High bonding strength, vibration and impact resistance

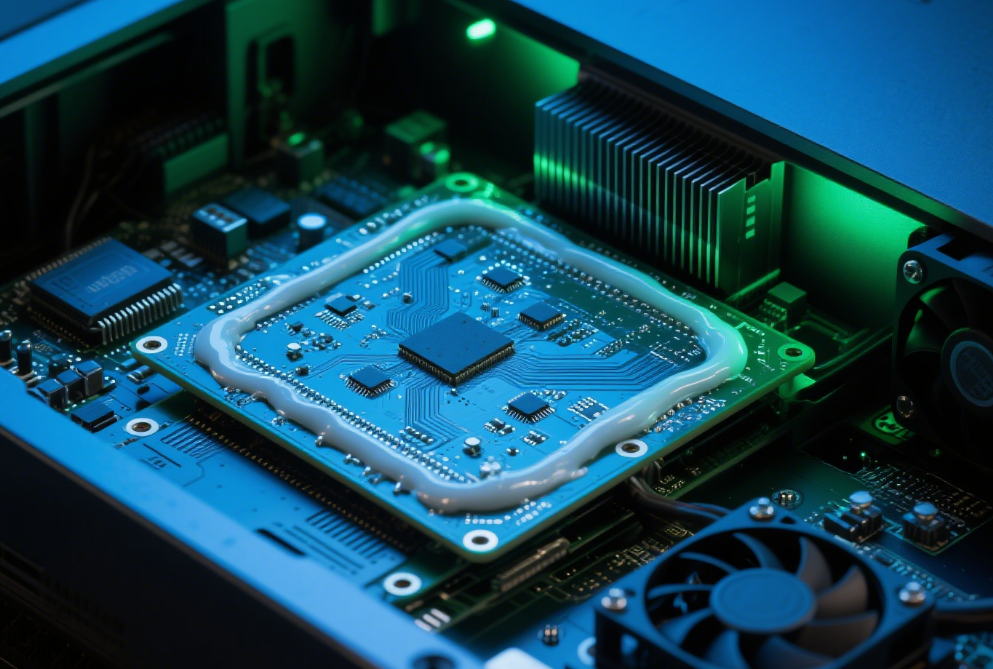

Core functions: Reliable bonding between optical chips and substrates.

Key technical requirements:

- Functional adaptability:

- High-power devices: High thermal conductivity (≥1.5W/(m·K))

- Sensitive components: High insulation (volume resistivity ≥10¹⁴Ω·cm)

- Process compatibility: Gentle curing process (≤120℃, ≤30min)

Core functions: Internal sealing, isolation from moisture and contaminants.

Key technical requirements:

- Material type: Epoxy resin or silicone-based

- Environmental resistance: Low VOC (≤100ppm), stable under 湿热 conditions (85℃/85% RH), ≥10-year lifespan

- Sealing performance: Dense adhesive layer, WVTR ≤1g/(m²·24h)

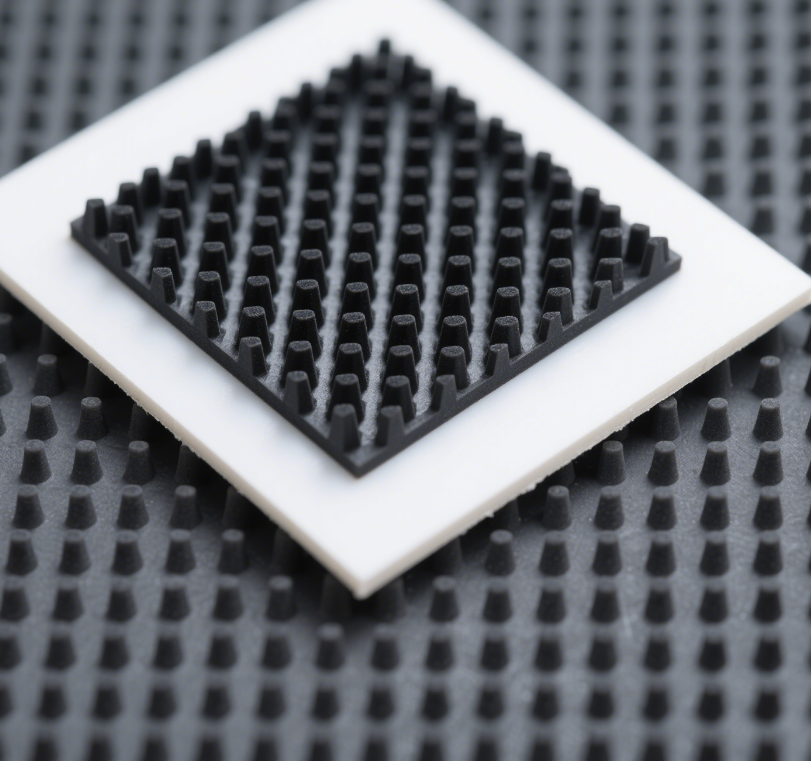

Core functions: Address heat dissipation in high-power modules.

Key technical requirements:

- Thermal performance: Thermal conductivity ≥2.0W/(m·K) for adhesives, ≥3.0W/(m·K) for pads

- Adaptability: Flexible, gap-filling capability, high temperature resistance (≥100℃)

Core functions: Block electromagnetic interference.

Key technical requirements:

- Conductive performance: Volume resistivity ≤10⁻³Ω·cm

- Shielding effectiveness: ≥30dB (matching module operating frequency)

Low refractive index matching adhesives:

- Core requirement: Refractive index close to optical fiber (1.45~1.50), reflection loss ≤0.5%

- Applications: Fiber connectors, optical coupling areas

Radiation-resistant adhesives:

- Core requirement: Resist γ and X-ray radiation (≥10⁵Gy) without significant degradation

- Applications: Space optical communication equipment, nuclear environment devices

Fast-curing adhesives:

- Core requirement: UV curing ≤10s or thermal curing ≤30s

- Applications: High-volume optical device production lines

Silicone-free/low-silicone adhesives:

- Core requirement: Silicon content ≤10ppm

- Applications: High-cleanliness optical modules, precision optical systems