Analysis of the Application of Flame-Retardant Protective Materials in Electric Vehicles

2025/10/21

0

With the rapid development of the new energy vehicle industry, the safety performance of electric vehicles (EVs) has gradually become one of the core focuses of consumers. Among various safety concerns, fire hazards are more prominent due to the characteristics of EV power batteries and high-voltage electrical systems. As a key solution to this hazard, flame-retardant protective materials have been widely used in multiple core parts of EVs. They fundamentally reduce fire risks, slow down the spread of flames, and provide important protection for the life safety of passengers and drivers as well as the property safety of vehicles.

I. Core Requirements of Electric Vehicles for Flame-Retardant Protective Materials

There are essential differences between EVs and traditional fuel vehicles in terms of power systems and structural design, which makes EVs have more stringent requirements for flame-retardant protective materials.

- Power batteries (such as lithium-ion batteries) release a large amount of heat and toxic gases during thermal runaway, and the fire spreads extremely fast. Therefore, the materials must have high-efficiency flame retardancy to quickly inhibit combustion reactions in high-temperature environments.

- The high-voltage electrical system of EVs (usually with a voltage of over 300V) operates under high load for a long time, which may cause local high temperatures due to wire aging or short circuits. Thus, the materials must meet the dual requirements of insulation and flame retardancy.

- Considering the health of passengers and drivers, the materials must also have low smoke and low toxicity properties. They should not release toxic gases such as carbon monoxide and hydrogen chloride during combustion to avoid secondary injuries.

- To adapt to the development trend of EV lightweighting, the materials must balance lightweight performance and mechanical properties, ensuring safety without adding excessive weight to the vehicle body.

II. Specific Application Scenarios of Flame-Retardant Protective Materials in Electric Vehicles

(I) Power Battery System: The Core Line of Defense for Fire Protection

The power battery is the main source of fire risk in EVs, and flame-retardant protective materials are used throughout the “inner and outer layers” of the battery pack.

- Inside the battery pack: Flame-retardant and heat-insulating gaskets (such as modified epoxy resin gaskets and ceramizable silicone rubber gaskets) are placed between battery cells. These materials can effectively block heat transfer during cell thermal runaway and prevent chain reactions among adjacent cells.

- Battery pack shell: Most shells are made of flame-retardant reinforced composite materials (such as glass fiber-reinforced polypropylene and flame-retardant ABS). These materials not only have high strength and impact resistance but also can prevent flame penetration in the early stage of external fire or internal thermal runaway.

- Wire harness wrapping of the battery pack: Flame-retardant heat-shrinkable tubes (such as polyolefin flame-retardant heat-shrinkable tubes) are used to avoid sparks caused by wire short circuits igniting surrounding materials.

(II) High-Voltage Electrical System: Dual Protection of Insulation and Flame Retardancy

Components such as high-voltage wire harnesses, connectors, and inverters in EVs need to have both insulation and flame retardancy.

- High-voltage wire harnesses: The insulation layer and sheath are mostly made of flame-retardant cross-linked polyethylene (XLPE) or flame-retardant polyvinyl chloride (PVC). These materials can not only withstand the test of high-voltage electric fields but also inhibit combustion when local overheating or short circuits occur.

- Connectors: The shell of connectors is usually made of flame-retardant nylon (such as flame-retardant grade PA66+GF30), which has high-temperature resistance and aging resistance, and can prevent sparks from leaking and causing fires.

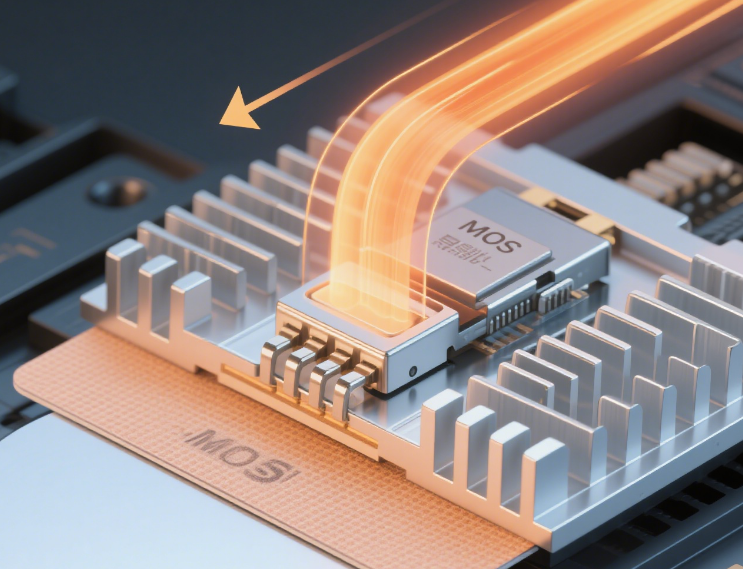

- Inverters: As the core component for power conversion, flame-retardant insulating paper (such as Nomex flame-retardant insulating paper) is used between the internal heat dissipation module and the circuit of inverters. It not only isolates current but also maintains stability in high-temperature environments, avoiding fires caused by insulation failure.

(III) Vehicle Body and Interior: Reducing the Risk of Fire Spread

Although the vehicle body structure and interior materials do not directly contact the high-voltage system, they can become “combustion accelerants” when a fire occurs. Therefore, flame-retardant materials are also required for these parts.

- Body plastic components: Parts such as bumpers and door panel frames are mostly made of flame-retardant polypropylene (PP + flame retardant), which can quickly form a carbon layer during combustion to inhibit flame spread.

- Interior materials:

- Seat fabrics often use flame-retardant polyester fibers (such as polyester cloth with phosphorus-based flame retardants).

- Carpets adopt flame-retardant polypropylene carpets.

- Instrument panel skins use flame-retardant polyurethane (PU) foam.

These materials can not only inhibit flames during combustion but also reduce the release of smoke and toxic gases, providing more escape time for passengers and drivers.

- Small interior parts: Components such as wire harness fixing clips and plastic decorative parts in the vehicle are also mostly made of flame-retardant plastics (such as flame-retardant PP and flame-retardant ABS), reducing fire risks in details.

III. Effectiveness and Development Trends of Flame-Retardant Protective Materials in EV Applications

Application Effectiveness

Flame-retardant protective materials have become a key factor in improving the safety performance of EVs. According to test data from the China Automotive Technology and Research Center (C-NCAP), EVs using compliant flame-retardant materials have the following advantages compared with models without flame-retardant materials in scenarios simulating battery thermal runaway or wire short circuits:

- The flame spread speed is reduced by more than 50%.

- The release of toxic gases is reduced by 40%.

These improvements provide a more sufficient escape window for passengers and drivers.

Development Trends

With the advancement of material technology, flame-retardant protective materials are developing towards environmental protection, high performance, and integration:

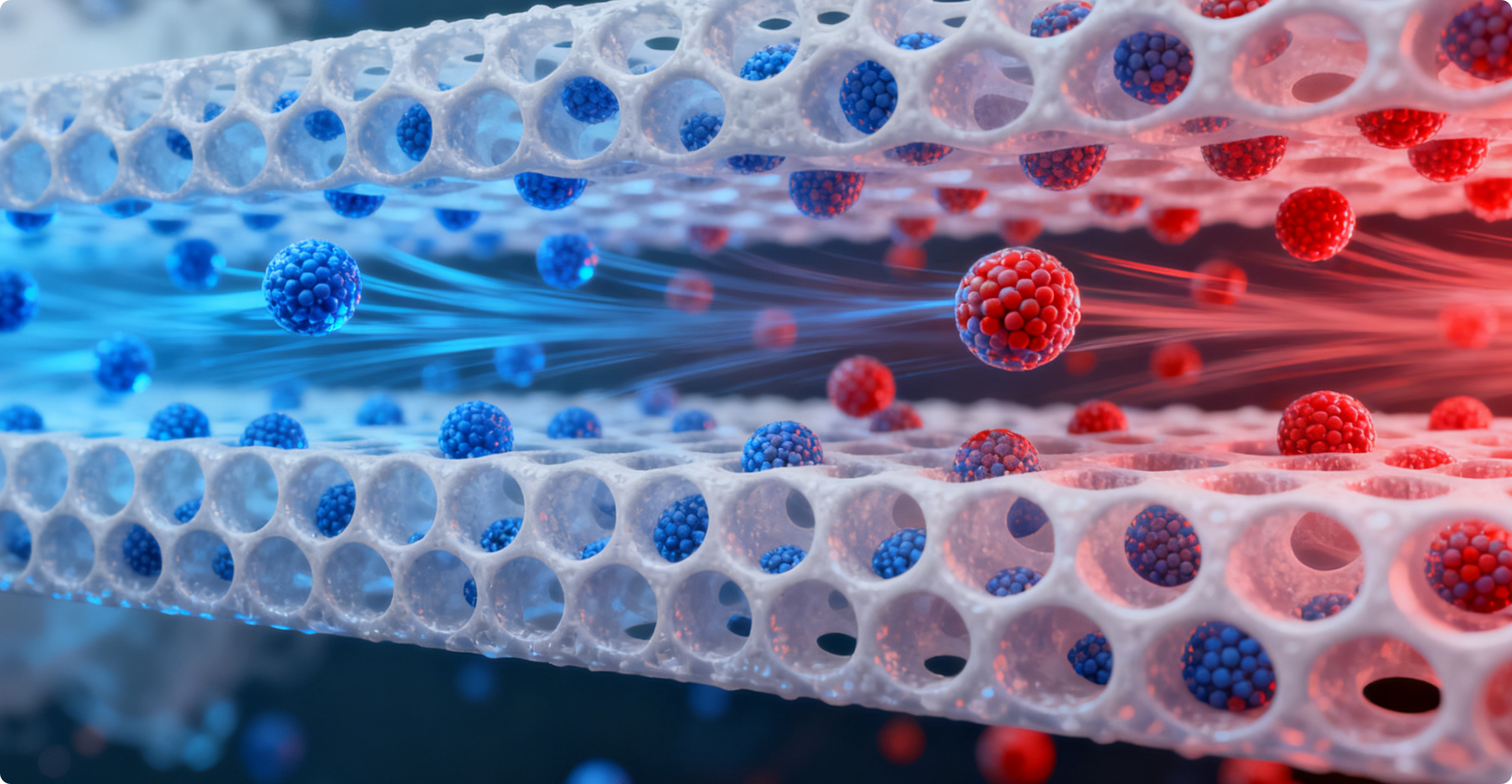

- Environmental protection: Traditional halogen-based flame retardants, which release toxic gases during combustion, are gradually being replaced by halogen-free flame retardants (such as phosphorus-based and nitrogen-based flame retardants) to achieve better environmental performance.

- Integration: The R&D and application of “flame retardancy + heat insulation + insulation” integrated materials (such as ceramizable silicone rubber) reduce the types of materials and assembly processes while improving comprehensive protection performance.

- Lightweight: The application of lightweight flame-retardant composite materials (such as carbon fiber-reinforced flame-retardant resin-based composite materials) helps EVs achieve a balance between “safety and lightweighting”.

IV. Conclusion

Against the background of the rapid development of the EV industry, flame-retardant protective materials have evolved from “auxiliary components” to “core safety guarantees”. Their application scenarios cover key systems such as power batteries, high-voltage electrical systems, and vehicle body interiors. Through properties such as high-efficiency flame retardancy, low smoke and low toxicity, and insulation, they build multiple lines of defense for the fire safety of EVs. In the future, with continuous breakthroughs in material technology and the continuous improvement of industry standards, flame-retardant protective materials will play a more important role in enhancing the safety performance of EVs and promoting the high-quality development of the new energy vehicle industry.

把“阻燃防护材料在电车上的应用解析”翻译成日语。

提供一些阻燃防护材料在电车上的应用实例。

阻燃防护材料在电车的哪些部位应用可以有效提高安全性?