Application of Silicone Sealant in Waterproof Electronic Devices

2025/07/14

0

Among the various protection technologies for waterproof electronic devices, silicone sealant plays a crucial role. With its unique properties, it serves as a key “barrier” for devices against water vapor intrusion and is widely used in the sealing processes of various electronic devices.

Core Functions of Silicone Sealant

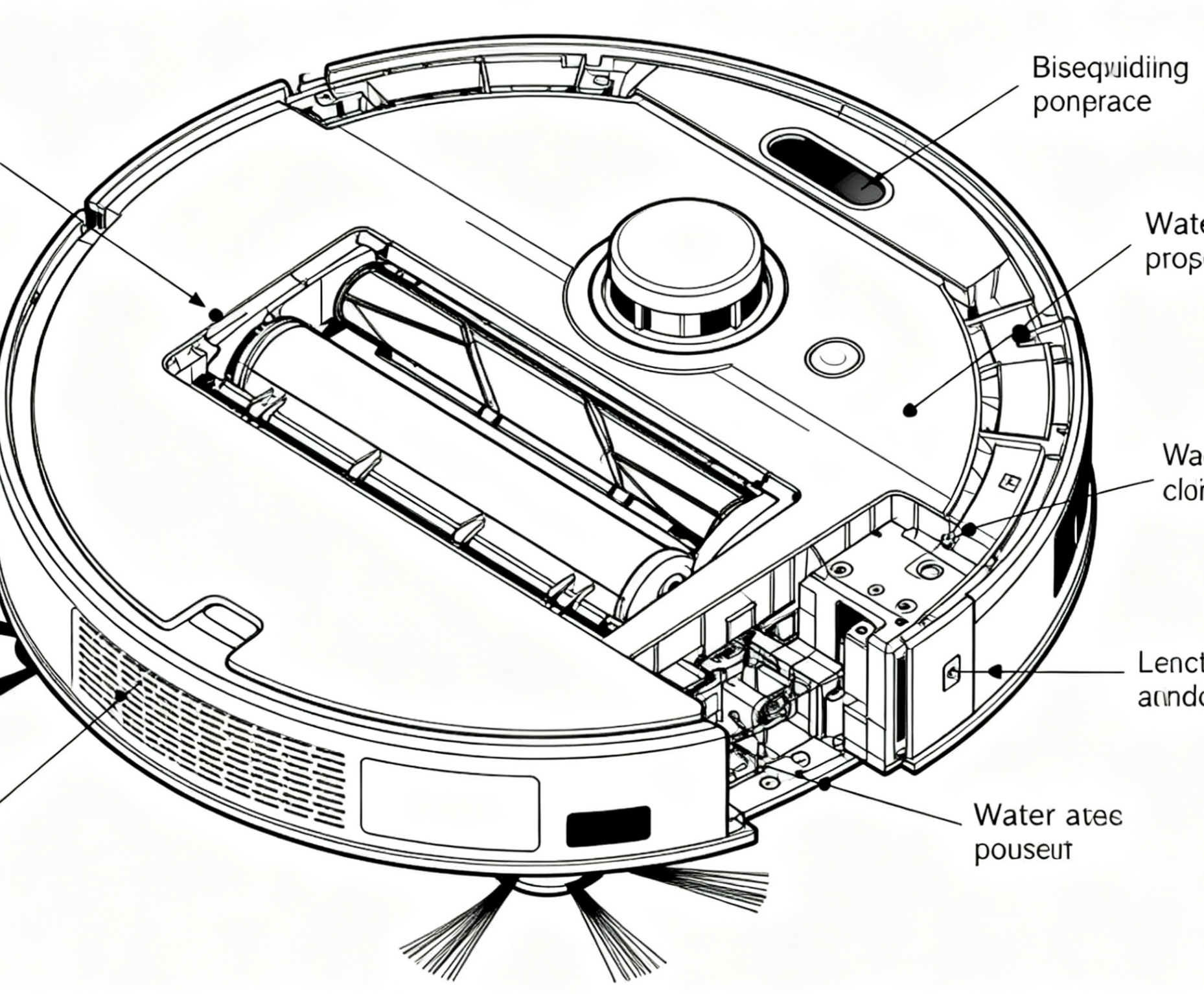

The main function of silicone sealant in waterproof electronic devices is to seal gaps. Tiny gaps often exist at the joints of electronic device casings, interface parts (such as charging ports and data interfaces), and connection points between components and casings. These gaps are the main channels for water vapor to enter the interior of the device. Silicone sealant can tightly fill these gaps, forming a continuous and flexible sealing layer, which effectively prevents water, moisture, dust, and other impurities from entering, thereby protecting internal electronic components from damage and ensuring the normal operation of the device.

Outstanding Advantages of Silicone Sealant

- Excellent waterproof performance: Silicone sealant has extremely low water absorption and can maintain good waterproof effects for a long time. Even in humid environments or underwater scenarios, it can stably exert its sealing effect, which is the core reason for its wide application in waterproof electronic devices.

- Good temperature resistance: Electronic devices generate a certain amount of heat during operation, and silicone sealant can maintain stable performance within a wide temperature range (usually from -60°C to 200°C or even higher). It will not crack, harden, or soften due to temperature changes, ensuring that the sealing effect is not affected.

- Excellent flexibility and elasticity: Devices may undergo slight deformation due to vibration, collision, or temperature changes during use. Silicone sealant has good flexibility and elasticity, which can expand and contract with the deformation of the device without seal failure, always maintaining a tight sealing state.

- Strong aging resistance: When exposed to the environment such as air, light, and temperature changes for a long time, silicone sealant is not prone to aging and deterioration, can maintain its sealing performance for a long time, and extend the service life of waterproof electronic devices.

- Good compatibility with various materials: The outer casing and internal components of electronic devices may be made of various materials such as plastic, metal, and glass. Silicone sealant can bond well with these materials without causing corrosion or chemical reactions, ensuring the structural stability of the device.

Typical Application Scenarios of Silicone Sealant

- Smartphones: Silicone sealant is used for sealing at the joints of the front and rear covers with the middle frame, the connection parts between the camera module and the body, and the gaps between the buttons and the casing. Together with other waterproof technologies, it achieves a high level of waterproofing for the phone.

- Smart watches / bracelets: Due to their small size and more precise structure, the connection between the watch case and the watch mirror, and the interface between the sensor and the casing rely on silicone sealant to form a reliable seal to cope with daily water contact scenarios such as swimming and hand washing.

- Action cameras: To meet the needs of underwater shooting, silicone sealant is essential for sealing key positions such as the body seams and the connection between the lens and the body of the action camera, ensuring that it can work normally in deep water environments.

- Outdoor Bluetooth speakers: The joints of the speaker casing and the installation gaps between the speaker and the casing are sealed with silicone sealant to prevent rainwater and splashed water from entering the interior and damaging the circuit and speaker components.

Key Points for Selection and Use of Silicone Sealant

When selecting silicone sealant, it is necessary to consider the usage environment of the device (such as temperature range, whether it is in contact with chemical substances, etc.), the stress situation of the sealing part, and the compatibility with related materials. At the same time, products that meet industry standards should be selected to ensure the sealing quality.

During use, it is necessary to ensure that the sealing part is clean and dry, apply the sealant in accordance with the specified process, control the thickness and uniformity of the adhesive layer, and ensure sufficient curing time so that the sealant can give full play to its performance. In addition, attention should be paid to the storage conditions of the sealant to avoid affecting its use effect due to improper storage.

In conclusion, with its excellent performance, silicone sealant plays an irreplaceable role in the sealing protection of waterproof electronic devices and is an important foundation for ensuring the waterproof performance of devices.