High-Insulation Sealant: A Reliable Protection Solution for Various Drivers

2025/07/07

0

In the field of modern industry and electronic equipment, various drivers play a crucial role. From servo drivers in industrial automation to motor controllers in new energy vehicles, their stable operation is directly related to the performance of the entire system. As the “close guardian” of drivers, high-insulation sealant is increasingly attracting widespread attention and application.

High-Insulation Sealant: A Reliable Protection Solution for Various Drivers

Characteristics of High-Insulation Sealant

Excellent Electrical Insulation Performance

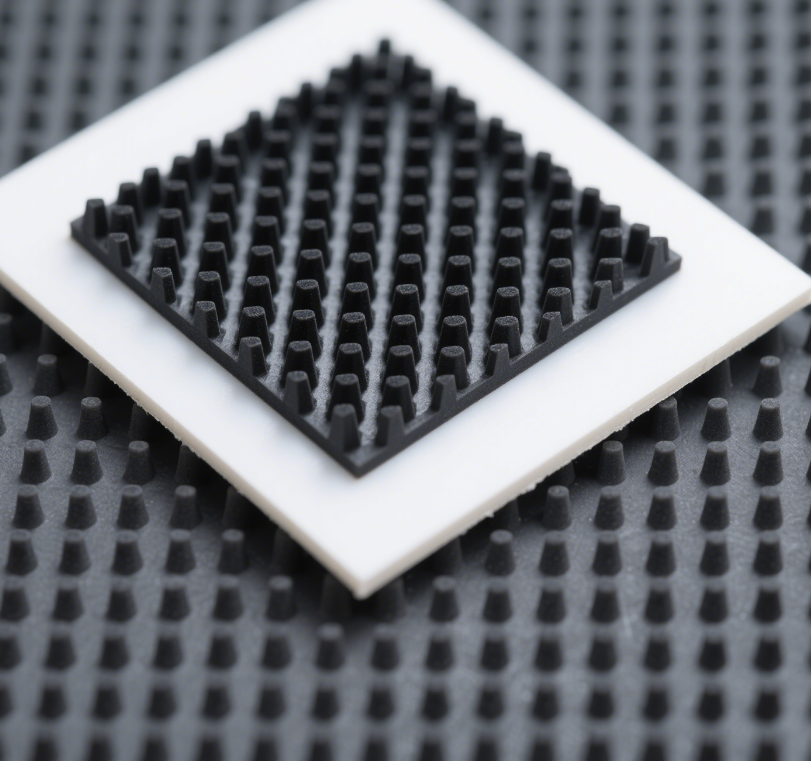

One of the core characteristics of high-insulation sealant is its outstanding electrical insulation capability. Take the common silicone-based high-insulation sealant as an example, its volume resistivity can be as high as over 1015Ω⋅cm, and the dielectric strength can reach 20–50 kV/mm. Such high insulation performance can build a solid “insulation barrier” inside the driver, effectively preventing current leakage and short circuits. In servo drivers, numerous precision electronic components are closely arranged, and minimal current leakage may interfere with signal transmission, causing abnormal equipment operation. High-insulation sealant precisely seals and isolates each component, ensuring that the current flows strictly along the established circuit path and maintaining the stable electrical performance of the driver.

Reliable Sealing Protection

After curing, this type of sealant can form a tight and continuous sealing layer, with excellent water-proof, dust-proof, and moisture-proof properties. Drivers used outdoors, such as wind power converters, are long-term exposed to the invasion of rainwater, dust, and high humidity. High-insulation sealant can achieve IP65 or even higher-level protection sealing, completely blocking moisture and dust particles from entering the interior of the driver, avoiding failures such as corrosion and short circuits caused by moisture and dust accumulation in electronic components, and significantly improving the reliability and service life of the driver in harsh environments.

Good Physical Properties

High-insulation sealant shows balanced physical properties such as hardness, flexibility, and temperature resistance. The cured sealant has moderate hardness, which can not only provide necessary mechanical support for the internal components of the driver to prevent component displacement and solder joint fracture caused by vibration and impact but also has a certain degree of flexibility to effectively buffer external stress and adapt to the slight deformation of the driver under different working conditions. In terms of temperature resistance, most products can maintain stable performance in the temperature range of -50°C to 200°C, meeting the operation requirements of various drivers in extreme high and low-temperature environments. For example, the motor driver in the engine compartment of a car, under the alternating working conditions of high-temperature radiation from the engine and low-temperature start in winter, the sealant can still stick to its post to ensure the normal operation of the equipment.

Application Advantages

Prolonging the Service Life of Drivers

Through excellent insulation and sealing protection, high-insulation sealant can greatly reduce the probability of damage to internal components of the driver due to electrical failures and environmental erosion. Studies have shown that after potting or sealing treatment with high-insulation sealant, the average trouble-free operation time of industrial drivers can be extended by 30%–50%, effectively reducing equipment maintenance costs and downtime and improving production efficiency.

Enhancing the Performance Stability of Drivers

A stable electrical insulation environment can ensure accurate signal transmission in the driver without interference, making the equipment operate more smoothly and efficiently. Tests on motor drivers have found that after using high-insulation sealant, the speed fluctuation range of the motor is significantly reduced, and the torque output is more stable, which is of great significance for industrial automation equipment with strict requirements for speed and precision, and can significantly improve product processing quality and equipment operation stability.

Adapting to Diverse Application Scenarios

Whether in high-temperature and high-humidity chemical production workshops or in cold and strong electromagnetic interference mining sites, high-insulation sealant can rely on its excellent comprehensive performance to provide reliable protection for various drivers. From PLC module drivers in the field of industrial control to power drivers of high-end outdoor equipment in consumer electronics, it can perfectly adapt, demonstrating strong environmental adaptability and application versatility.

Application Cases

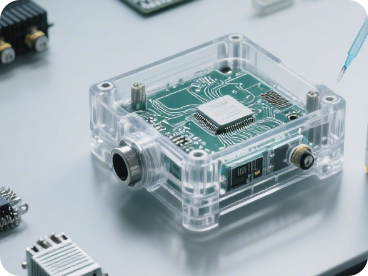

Servo Drivers in Industrial Automation

In automated production lines, servo drivers are responsible for precisely controlling the operation of motors, and their performance directly affects product production accuracy and efficiency. A well-known automation equipment manufacturer used a high-insulation silicone sealant for potting treatment in its new servo driver. After long-term actual operation monitoring, the failure rate of this driver in complex electromagnetic environments and frequent start-stop conditions was reduced by 40% compared with the previous product, and the equipment operation stability and control accuracy were significantly improved, effectively helping enterprises improve production efficiency and reduce the defective rate.

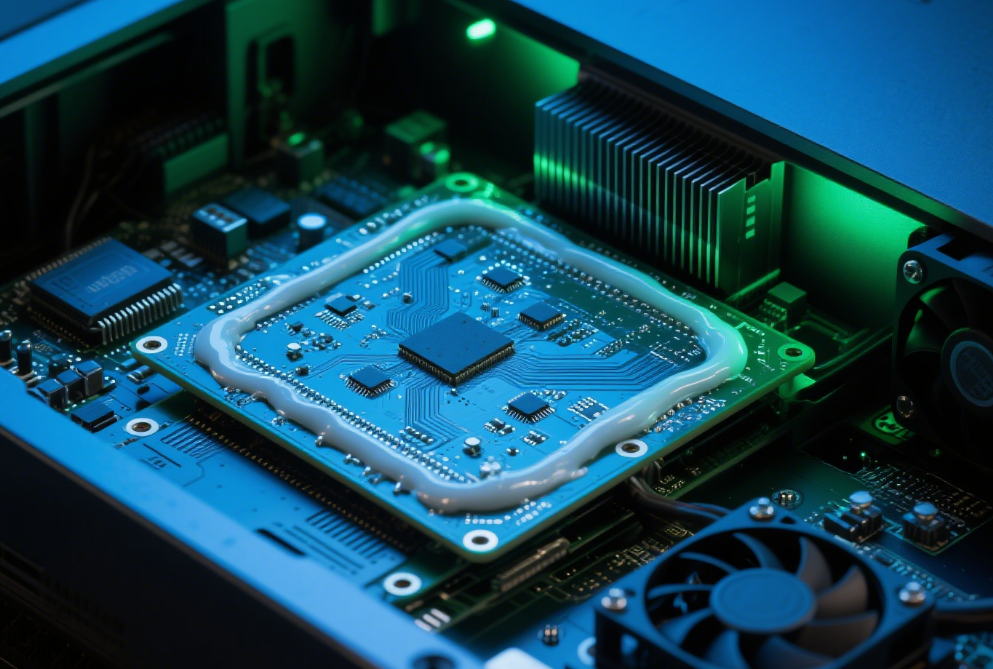

Motor Controllers of New Energy Vehicles

As the core component of the power system of new energy vehicles, the motor controller works in an extremely harsh environment, which not only needs to withstand high voltage and large current but also needs to cope with the vibration, impact, and temperature changes during vehicle driving. A domestic new energy vehicle enterprise introduced high-insulation sealant in the manufacturing of motor controllers to seal and protect key parts such as internal circuit boards and power modules. After multiple rounds of extreme condition tests, including high-temperature exposure, wading driving, and high-intensity off-road road conditions, the motor controller has always maintained stable operation without performance degradation caused by electrical failures or environmental factors, effectively ensuring the power performance and driving safety of the whole vehicle.

In the current era of continuous evolution of driver technology and increasingly complex application scenarios, high-insulation sealant is becoming a key material to ensure the reliable operation of drivers and improve the overall performance of equipment by virtue of its unique advantages. With the continuous innovation of material technology, it is believed that high-insulation sealant will play a greater role in more fields and more types of drivers, injecting strong impetus into the development of industry and electronics.