Thermal Conductive Pad in Diagnostic Equipment

2025/06/27

0

In the operation of diagnostic equipment, effective thermal management is crucial for maintaining the performance, reliability, and lifespan of the devices. Thermal conductive pads have become an essential component in this regard, playing a vital role in dissipating heat generated by various components within diagnostic equipment.

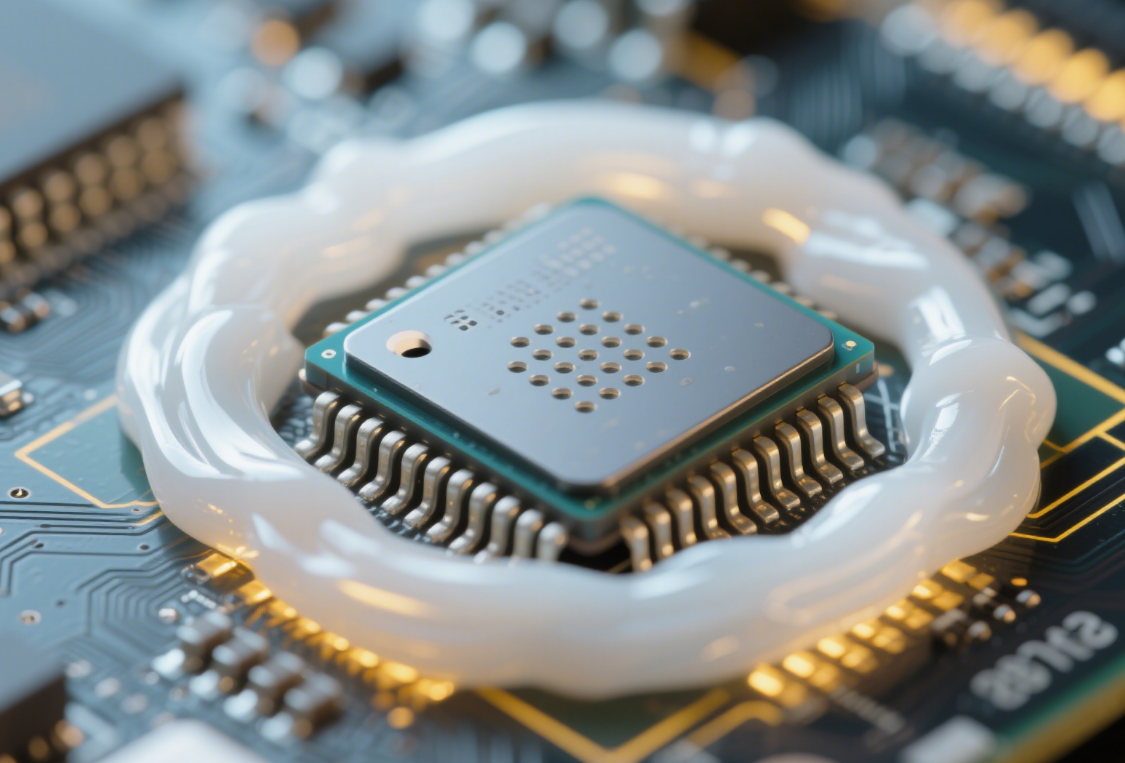

Thermal conductive pads are typically made from a combination of elastomeric materials, such as silicone or polyurethane, and thermally conductive fillers, such as aluminum oxide, boron nitride, or zinc oxide. These fillers are dispersed throughout the elastomeric matrix, creating a material with high thermal conductivity that can efficiently transfer heat from heat-generating components to heat sinks or cooling systems.

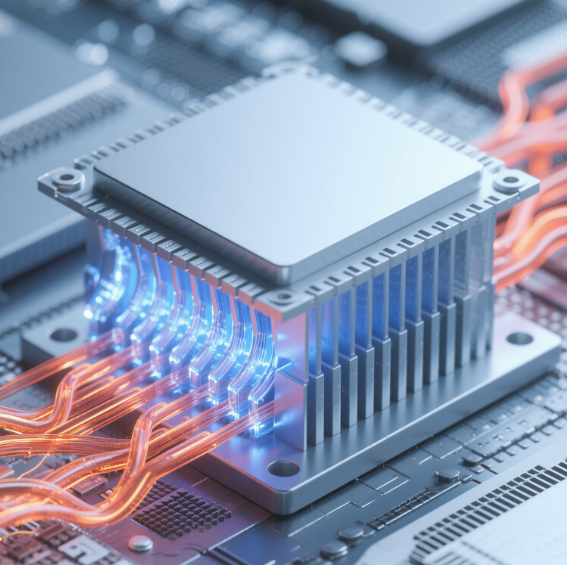

One of the primary applications of thermal conductive pads in diagnostic equipment is in electronic components. Components such as integrated circuits (ICs), power transistors, and microprocessors generate significant amounts of heat during operation. If this heat is not effectively dissipated, it can lead to overheating, which can cause performance degradation, component failure, and even damage to the entire diagnostic device. Thermal conductive pads are placed between these components and the heat sinks or cooling systems to create a thermal interface that maximizes heat transfer. The pads conform to the irregular surfaces of the components and heat sinks, eliminating air gaps that can act as thermal barriers and ensuring efficient heat dissipation.

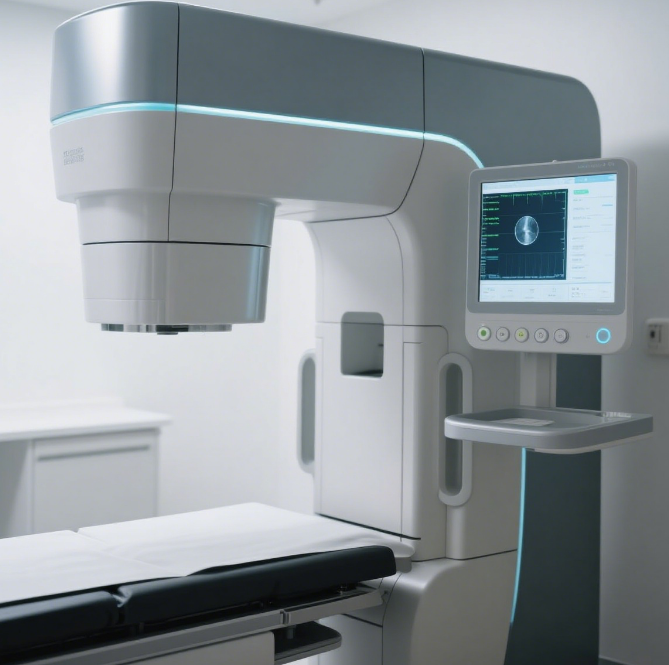

In addition to electronic components, thermal conductive pads are also used in other parts of diagnostic equipment, such as X-ray tubes and detectors. X-ray tubes generate a large amount of heat during operation, and effective thermal management is essential to prevent damage to the tube and ensure its long-term reliability. Thermal conductive pads are used to transfer heat from the X-ray tube to the cooling system, helping to maintain the optimal operating temperature of the tube. Similarly, in detectors, thermal conductive pads are used to dissipate heat generated by the sensor elements, ensuring accurate and consistent signal detection.

Another important application of thermal conductive pads is in medical imaging equipment, such as MRI scanners and CT scanners. These devices contain complex electronic and mechanical components that generate heat during operation. Thermal conductive pads are used to manage the heat generated by these components, ensuring the stable operation of the equipment and the quality of the imaging results. By effectively dissipating heat, thermal conductive pads help to prevent thermal distortion of the imaging components, which can lead to image artifacts and reduced diagnostic accuracy.

The use of thermal conductive pads in diagnostic equipment offers several advantages. Firstly, it helps to improve the performance and reliability of the equipment by preventing overheating and ensuring the optimal operating temperature of the components. This reduces the risk of component failure and extends the lifespan of the diagnostic device. Secondly, it helps to improve the accuracy and consistency of the diagnostic results by preventing thermal distortion of the imaging components. Finally, it helps to reduce the need for complex and expensive cooling systems, as the thermal conductive pads can effectively transfer heat with relatively simple heat sinks or air cooling solutions.

However, the use of thermal conductive pads also presents some challenges. One of the main challenges is the selection of the appropriate pad material and thickness for a specific application. Different applications may require different levels of thermal conductivity, flexibility, and compressibility, and manufacturers need to carefully consider these factors when choosing the thermal conductive pad. Additionally, the long-term performance of thermal conductive pads can be affected by factors such as temperature cycling, mechanical stress, and chemical exposure, and manufacturers need to ensure that the pads can withstand these environmental conditions without losing their thermal conductivity and other properties.

In conclusion, thermal conductive pads are an essential component in modern diagnostic equipment. Their ability to efficiently transfer heat from heat-generating components to heat sinks or cooling systems ensures the optimal operation of the equipment, improves the accuracy and reliability of the diagnostic results, and extends the lifespan of the devices. As the complexity and performance requirements of diagnostic equipment continue to increase, the development and application of thermal conductive pads are likely to become even more important in the future.