wave-absorbing rubber in navigation systems

2025/06/18

0

In the realm of modern navigation systems, wave – absorbing rubber has emerged as a crucial component, playing a significant role in enhancing the performance and reliability of these systems. Navigation systems, whether for maritime vessels, aircraft, or land – based vehicles, rely on the accurate transmission and reception of electromagnetic waves. However, interference from unwanted waves can severely degrade the functionality of these systems. This is where wave – absorbing rubber comes into play.

Properties of Wave – Absorbing Rubber

Wave – absorbing rubber is engineered with unique material properties. It is typically composed of a matrix of rubber polymers combined with special fillers and additives. The rubber matrix provides flexibility and durability, which are essential for withstanding the harsh environmental conditions that navigation systems often encounter, such as temperature fluctuations, humidity, and mechanical vibrations.

The key to its wave – absorbing ability lies in the carefully selected fillers. These fillers, often including materials like carbonyl iron powder, ferrite, or conductive carbon black, interact with electromagnetic waves. When electromagnetic waves encounter the wave – absorbing rubber, the fillers cause the waves to be dissipated as heat through various physical and chemical processes. This conversion of wave energy into heat effectively reduces the reflection and scattering of waves, minimizing interference within the navigation system.

Applications in Navigation Systems

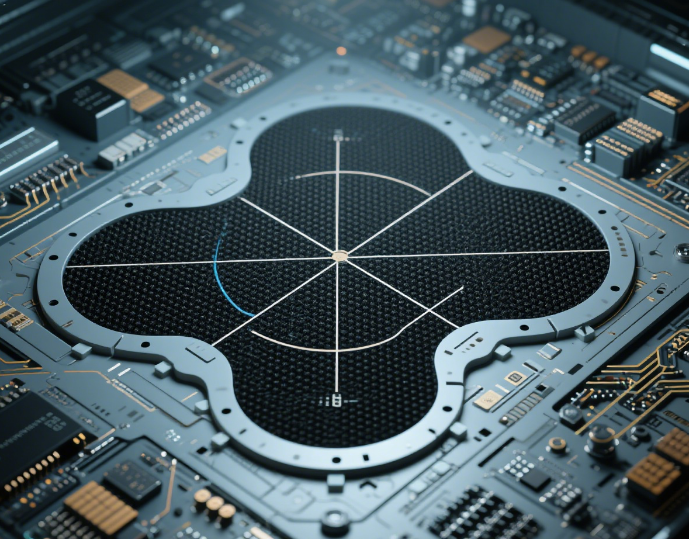

Antenna Systems

Antennas are the primary components of navigation systems responsible for transmitting and receiving signals. In an ideal scenario, antennas should operate without interference, ensuring clear and accurate signal communication. However, in real – world applications, external electromagnetic waves can bounce off nearby surfaces and interfere with the signals received or transmitted by the antenna. Wave – absorbing rubber is often used to line the enclosures of antennas or to create shielding structures around them. By absorbing the unwanted waves, it improves the signal – to – noise ratio, allowing the antenna to operate more efficiently. This results in better signal reception, enhanced accuracy of navigation data, and a more stable connection.

On – Board Electronics

Navigation systems are equipped with a variety of on – board electronics, such as receivers, transmitters, and signal processors. These components are sensitive to electromagnetic interference (EMI). Wave – absorbing rubber can be integrated into the casings of these electronic devices or used as gaskets and seals. It helps to isolate the electronics from external EMI sources, preventing signal distortion and malfunctions. For example, in a maritime navigation system, where the vessel is surrounded by a complex electromagnetic environment due to the presence of other electrical equipment on board and external radio signals, wave – absorbing rubber safeguards the on – board electronics, ensuring the integrity of the navigation data.

Structural Components

In addition to protecting the electronic components, wave – absorbing rubber can also be applied to the structural components of navigation systems. In aircraft and maritime vessels, for instance, the use of wave – absorbing rubber in the fuselage or hull structures can reduce the radar cross – section. By absorbing the radar waves instead of reflecting them, it helps in stealth applications, making the vehicle less detectable by radar systems. This is not only important for military navigation systems but also has potential applications in civilian aviation and shipping, where reducing the radar signature can enhance safety and security in certain scenarios.

Advantages of Using Wave – Absorbing Rubber in Navigation Systems

Improved Signal Quality

As mentioned earlier, the primary advantage of wave – absorbing rubber is its ability to improve signal quality. By reducing interference, it ensures that the navigation system can receive and process accurate signals, leading to more precise positioning and navigation. This is crucial for applications where even a small error in navigation data can have significant consequences, such as in autonomous vehicles or long – range aircraft flights.

Enhanced System Reliability

Navigation systems are often used in critical applications, and any malfunction can lead to serious safety issues. Wave – absorbing rubber helps to enhance the reliability of these systems by protecting the sensitive electronics from EMI. It reduces the likelihood of system failures due to interference – related problems, ensuring that the navigation system operates smoothly and continuously.

Cost – Effectiveness

Although the initial cost of implementing wave – absorbing rubber in navigation systems may seem high, in the long run, it proves to be cost – effective. By improving the performance and reliability of the system, it reduces the need for frequent maintenance and repairs. Additionally, it extends the lifespan of the navigation system components, saving on replacement costs.

Future Developments

The field of wave – absorbing rubber for navigation systems is constantly evolving. Researchers are exploring new materials and manufacturing techniques to further improve the wave – absorbing performance of rubber. For example, the development of nanocomposite materials, where nanoscale fillers are incorporated into the rubber matrix, shows great promise. These nanocomposites can potentially offer higher wave – absorption efficiency in a wider frequency range, making them suitable for future – generation navigation systems that operate at higher frequencies.

Another area of development is the integration of smart materials into wave – absorbing rubber. Smart materials can change their properties in response to external stimuli, such as temperature, pressure, or electromagnetic fields. By incorporating smart materials, wave – absorbing rubber could adapt its wave – absorption characteristics in real – time, optimizing the performance of navigation systems under different operating conditions.

In conclusion, wave – absorbing rubber has become an indispensable part of modern navigation systems. Its unique properties and wide range of applications contribute significantly to improving the performance, reliability, and efficiency of these systems. With continuous research and development, wave – absorbing rubber is expected to play an even more important role in the future of navigation technology.