Silicone Sealant in the Field of Unmanned Aerial Vehicles (UAVs)

2025/06/17

0

1. Introduction

Unmanned Aerial Vehicles (UAVs), commonly known as drones, have witnessed a remarkable surge in applications across diverse fields in recent years. From military surveillance and reconnaissance to civilian uses such as aerial photography, delivery services, agricultural monitoring, and disaster relief operations, UAVs have become an integral part of modern life.

The successful operation of UAVs heavily relies on the reliability and performance of their components. These components are often exposed to a wide range of harsh environmental conditions, including extreme temperature variations, high humidity, dust, vibrations, and mechanical stresses during flight. To ensure the durability, functionality, and safety of UAVs under such demanding circumstances, the use of high – quality materials, especially sealants, is of utmost importance. Silicone sealants, with their unique set of properties, have emerged as a preferred choice for various applications within the UAV industry.

2. Properties of Silicone Sealants

2.1 Temperature Resistance

Silicone sealants exhibit exceptional temperature resistance. They can maintain their physical and chemical properties over an extremely wide temperature range, typically from as low as – 115°C (-175°F) to as high as 260°C (500°F). In the context of UAVs, this is crucial as drones may operate in cold high – altitude regions or in hot desert environments. For example, during winter operations in polar regions, the low – temperature flexibility of silicone sealants ensures that they do not become brittle and crack, which could lead to air leaks or component failures. Conversely, when UAVs are flying in close proximity to heat – generating components such as engines or high – power electronics, the high – temperature stability of silicone sealants prevents degradation and maintains the integrity of the sealed joints.

2.2 Flexibility and Vibration Damping

UAVs are subject to continuous vibrations during flight due to the operation of their motors and propellers. Silicone sealants are highly flexible materials. Their flexibility allows them to absorb and dampen these vibrations, protecting the components within the UAV from the harmful effects of mechanical stress. This is particularly important for components such as electronic circuit boards, sensors, and connectors. By reducing vibrations, silicone sealants help to prevent solder joint failures, loose connections, and damage to delicate sensor elements, thus enhancing the overall reliability and lifespan of the UAV.

2.3 Dielectric and Thermal Insulation

Good dielectric properties make silicone sealants excellent electrical insulators. In UAVs, which are equipped with a complex network of electrical and electronic systems, preventing electrical short – circuits and interference is crucial. Silicone sealants can effectively isolate electrical components from each other and from the external environment, ensuring the proper functioning of the avionics and control systems. Additionally, silicone sealants offer thermal insulation properties. They can help to regulate the temperature of sensitive components by reducing heat transfer. This is beneficial for components such as batteries, which can be affected by temperature fluctuations, and high – power electronics that generate heat during operation. By providing thermal insulation, silicone sealants contribute to the efficient operation and longevity of these components.

2.4 UV and Ozone Resistance

UAVs are often used outdoors, where they are exposed to sunlight and ozone in the atmosphere. Silicone sealants have excellent resistance to ultraviolet (UV) radiation and ozone. UV rays can cause degradation and discoloration in many materials over time, but silicone sealants remain stable and retain their mechanical and sealing properties even after prolonged exposure to sunlight. Ozone, which is present in the upper atmosphere and can also be generated in some industrial environments, can also attack and degrade materials. The ozone resistance of silicone sealants ensures that they do not deteriorate when UAVs are operating in such environments, maintaining the integrity of the sealed areas.

2.5 Adhesion

Silicone sealants can form strong bonds with a variety of materials commonly used in UAV construction, including metals (such as aluminum and titanium), plastics (such as polycarbonate and acrylonitrile – butadiene – styrene), and composites. The adhesion of silicone sealants provides structural integrity to the joints and assemblies within the UAV. For example, in the attachment of wings to the fuselage or the installation of sensors on the airframe, the strong adhesion of silicone sealants helps to ensure that these components remain securely in place during flight, even under the influence of aerodynamic forces and vibrations.

2.6 Curing Properties

Most silicone sealants cure at room temperature, which is highly convenient for UAV manufacturing and maintenance processes. Room – temperature curing eliminates the need for specialized heating equipment or high – temperature curing ovens, reducing production costs and time. Additionally, some silicone sealants offer fast – curing options, which can be beneficial for quick repairs or when time is of the essence. The curing process of silicone sealants also typically involves minimal shrinkage, ensuring that the sealed joints maintain their integrity and dimensional stability after curing.

2.7 Low Outgassing

In applications where airtightness and cleanliness are critical, such as in UAVs used for sensitive scientific measurements or in high – altitude operations, low – outgassing silicone sealants are preferred. Outgassing refers to the release of volatile substances from a material over time. High – outgassing materials can contaminate the internal environment of the UAV, affect the performance of sensors, or cause problems in the operation of delicate optical or electronic components. Low – outgassing silicone sealants meet or exceed ASTM E595 testing standards, ensuring that they release minimal volatile compounds and are suitable for use in UAVs where a clean and stable internal environment is required.

3. Applications of Silicone Sealants in UAVs

3.1 Battery Management

3.1.1 PCB Encapsulation

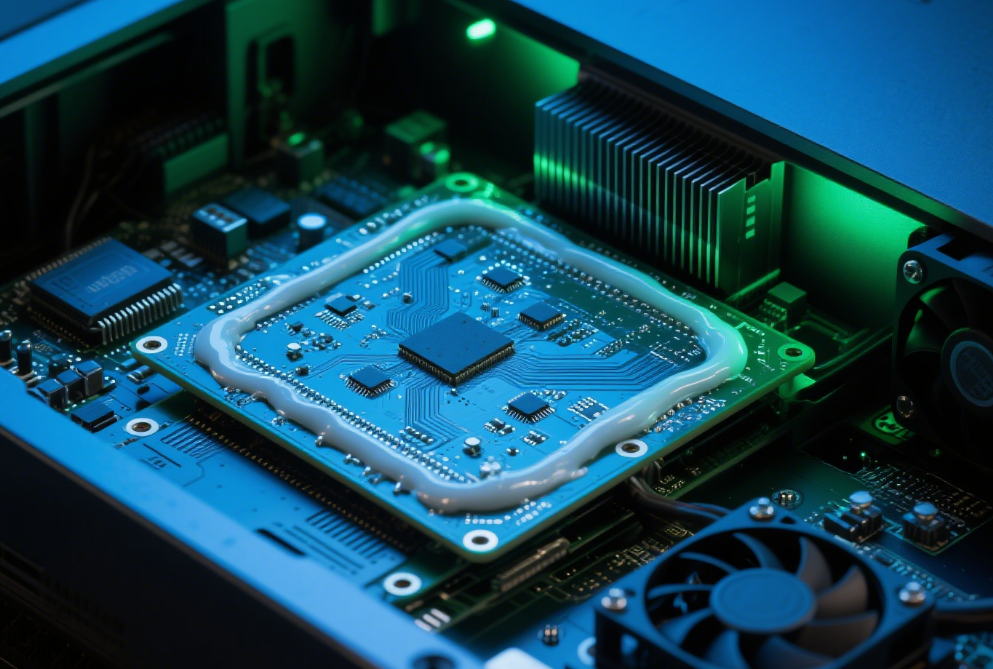

The printed circuit boards (PCBs) in UAV batteries are responsible for controlling the charging and discharging processes, as well as protecting the battery cells from over – voltage, over – current, and short – circuits. Silicone sealants are used to encapsulate these PCBs. Encapsulation with silicone sealants provides environmental protection, preventing moisture, dust, and contaminants from coming into contact with the sensitive electronic components on the PCB. This helps to prevent corrosion, electrical short – circuits, and component failures, thus extending the lifespan of the battery management system.

3.1.2 Vibration Dampening

Battery packs in UAVs are subject to vibrations during flight. These vibrations can cause mechanical stress on the battery cells and the associated electronic components, potentially leading to loose connections or damage. Silicone sealants, with their flexibility and vibration – damping properties, are applied around the battery cells and between the battery pack and the UAV frame. They absorb and dissipate the vibrations, reducing the mechanical stress on the battery components and improving the reliability of the battery system.

3.1.3 Battery Potting

Potting involves filling the empty spaces within a battery pack with a protective material. Silicone sealants are often used for battery potting in UAVs. The potting process with silicone sealants helps to protect the battery cells from physical damage, such as impacts and shocks. It also provides additional thermal management by improving heat transfer between the battery cells and the surrounding environment. In case of a thermal runaway event in a battery cell, the silicone potting material can also help to contain the heat and prevent it from spreading to other cells, enhancing the safety of the battery pack.

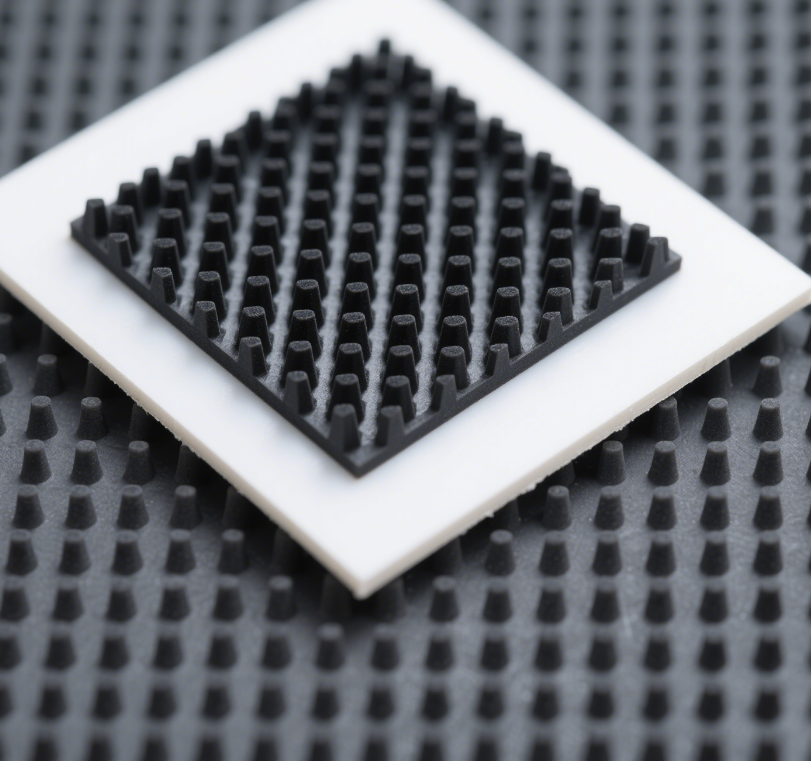

3.1.4 Thermal Adhesion

Efficient heat dissipation is crucial for the performance and lifespan of UAV batteries. Silicone sealants with high thermal conductivity can be used as thermal adhesives to bond heat sinks to the battery cells or the battery management PCB. These thermal adhesives effectively transfer the heat generated by the battery components to the heat sink, which then dissipates the heat into the surrounding air. By improving thermal management, silicone – based thermal adhesives help to keep the battery operating within an optimal temperature range, reducing the risk of overheating and improving the overall efficiency of the battery.

3.1.5 Flame Suppressant

In some UAV applications, especially those where safety is a top priority, silicone sealants with flame – suppressant properties can be used in the battery area. In the event of a fire or an electrical short – circuit that could potentially lead to a fire, these flame – suppressant silicone sealants can help to slow down or prevent the spread of the fire. They can form a protective char layer when exposed to high temperatures, which acts as a barrier and reduces the oxygen supply to the burning material, thus extinguishing or suppressing the fire.

3.2 Connectors

3.2.1 Waterproofing Pin Connectors

UAVs may operate in various weather conditions, including rain and high humidity environments. Pin connectors, which are used to connect different electrical components within the UAV, are vulnerable to water ingress. Silicone sealants are used to seal the gaps around pin connectors, creating a waterproof barrier. This prevents water from entering the connectors and causing electrical corrosion or short – circuits. The flexibility of silicone sealants allows them to conform to the irregular surfaces of the connectors and provide a reliable and long – lasting waterproof seal.

3.2.2 Non – Corrosive Bonding

Connectors in UAVs are often made of different materials, such as metals and plastics. The dissimilar materials can be prone to galvanic corrosion when exposed to moisture and an electrolyte. Silicone sealants, which are chemically inert, can be used to bond these different materials together. By creating a non – corrosive bond, silicone sealants prevent the occurrence of galvanic corrosion, ensuring the long – term reliability of the connectors and the proper functioning of the electrical connections within the UAV.

3.3 EMI Shielding

3.3.1 Gap Filling

Electromagnetic interference (EMI) can disrupt the operation of UAV avionics and communication systems. EMI shielding is essential to protect these sensitive components. Silicone sealants can be used as gap – filling materials in EMI shielding enclosures. These enclosures are designed to contain and block electromagnetic waves. The silicone sealant fills the gaps and seams in the enclosure, ensuring that there are no openings through which EMI can penetrate. The soft and flexible nature of silicone sealants allows them to fill irregular gaps effectively, providing a continuous and effective EMI – shielding barrier.

3.3.2 Thermal Management

In addition to EMI shielding, the components within an EMI – shielded enclosure may generate heat. Silicone sealants with thermal conductivity can be used in these applications to manage heat. They can transfer the heat generated by the components to the enclosure walls, which can then dissipate the heat into the surrounding environment. By combining EMI – shielding and thermal management functions, silicone sealants help to ensure the proper operation of UAV electronics in a high – performance and reliable manner.

3.3.3 EMI

Some silicone sealants are formulated with conductive fillers, such as metal particles or carbon nanotubes. These conductive silicone sealants can be used to create an electrically conductive path within the EMI – shielding enclosure. This conductive path helps to redirect and dissipate electromagnetic energy, further enhancing the EMI – shielding effectiveness of the enclosure. The use of conductive silicone sealants in UAVs is particularly important in applications where strong electromagnetic interference from external sources, such as radar systems or high – voltage power lines, may be encountered.

3.4 O – Ring / Case Sealing

3.4.1 Protection Against Environmental Factors

O – rings made of silicone are commonly used in UAVs for sealing various cases and enclosures, such as those housing avionics, cameras, and sensors. These O – rings provide a reliable seal against environmental factors such as dust, water, and moisture. The high resistance of silicone to these environmental factors ensures that the components inside the cases are protected from damage. For example, in UAVs used for agricultural spraying, where they may be exposed to dust and water from the fields, silicone O – rings effectively seal the camera and sensor enclosures, preventing the ingress of contaminants that could affect the performance of these components.

3.4.2 Maintaining Pressure and Sealing Integrity

In some UAV applications, such as high – altitude flights or flights in areas with significant pressure changes, maintaining the internal pressure within certain components is crucial. Silicone O – rings can maintain the pressure differential across the sealed surfaces and ensure the integrity of the seal. Their ability to withstand pressure variations and maintain a tight seal is due to their flexibility and resilience. The silicone O – rings can expand or contract slightly in response to pressure changes, preventing air leaks and maintaining the proper operating conditions for the components inside the sealed cases.

3.5 Sensor Coating, Potting, and Sealing

3.5.1 Sensor Coating

UAV sensors, such as gyroscopes, accelerometers, and GPS sensors, are highly sensitive to their environment. Silicone sealants can be used to coat these sensors. The coating provides a protective layer that shields the sensors from moisture, dust, and chemical contaminants. This protection helps to prevent sensor drift, improve the accuracy of the sensor readings, and extend the lifespan of the sensors. For example, in UAVs used for environmental monitoring, where sensors may be exposed to harsh chemicals in the air or water, the silicone coating on the sensors helps to maintain their performance over time.

3.5.2 Sensor Potting

Similar to battery potting, sensor potting with silicone sealants is used to protect the delicate sensor elements from physical damage and environmental factors. The potting material fills the voids around the sensor components, providing mechanical support and shock absorption. It also helps to isolate the sensors from external vibrations and electromagnetic interference, ensuring stable and accurate sensor operation. In UAVs used for precision mapping or surveying, the accurate performance of sensors is critical, and sensor potting with silicone sealants plays an important role in achieving this.

3.5.3 Sensor Sealing

Sealing the sensors within their enclosures is essential to prevent the ingress of moisture and contaminants. Silicone sealants are used to create a tight seal around the sensor housing, ensuring that the internal environment of the sensor remains clean and dry. This is particularly important for optical sensors, such as cameras and LiDAR sensors, where even a small amount of moisture or dust can affect the quality of the data they collect. The excellent adhesion and sealing properties of silicone sealants make them an ideal choice for sensor sealing applications in UAVs.

3.6 Optical Bonding

3.6.1 For Enhanced User Displays

In UAVs with on – board displays for real – time monitoring of flight data or live video feeds, optical bonding using silicone sealants can be employed. Optical bonding involves bonding a protective cover glass or a touch – screen panel to the display panel. Silicone sealants used for optical bonding have high optical clarity, which ensures that there is minimal loss of image quality or brightness. They also provide a strong bond between the different layers, protecting the display from mechanical damage and environmental factors. The use of silicone sealants in optical bonding can improve the visibility and durability of the UAV’s user displays, especially in outdoor or harsh operating conditions.

4. Challenges and Future Trends

4.1 Challenges in Silicone Sealant Application in UAVs

4.1.1 Compatibility with New Materials

As the UAV industry continues to evolve, new materials are being developed and used in UAV construction to improve performance, reduce weight, and increase efficiency. Ensuring the compatibility of silicone sealants with these new materials can be a challenge. For example, some advanced composite materials or novel alloys may have surface chemistries that are not well – understood in terms of their interaction with silicone sealants. Incompatibility can lead to poor adhesion, reduced sealing performance, or even degradation of the materials over time.

4.1.2 Meeting Stringent Performance Requirements

UAVs are expected to perform in increasingly demanding environments and applications. This requires silicone sealants to meet even more stringent performance requirements. For instance, in long – endurance UAVs for high – altitude atmospheric research, the sealants need to maintain their properties over extended periods of time under extreme temperature, pressure, and radiation conditions. Developing silicone sealants that can consistently meet these high – performance demands is a significant challenge for material scientists and manufacturers.

4.1.3 Cost – Effectiveness

While silicone sealants offer many advantages, cost can be a limiting factor in their widespread use in UAVs, especially in mass – produced consumer – grade drones. The manufacturing process of high – performance silicone sealants, including the use of specialized raw materials and production techniques, can be costly. Balancing the need for high – quality, high – performance silicone sealants with the cost – sensitivity of the UAV market is a challenge that the industry needs to address.

4.2 Future Trends in Silicone Sealant Use in UAVs

4.2.1 Development of Specialized Silicone Sealants

In the future, we can expect to see the development of more specialized silicone sealants tailored specifically for different UAV applications. For example, there may be silicone sealants with enhanced self – healing properties for use in UAVs operating in harsh mechanical environments where minor damage to the sealant may occur. There could also be sealants with improved anti – microbial properties for UAVs used in medical or food – related applications to prevent the growth of bacteria and fungi.

4.2.2 Integration with Smart Materials and Systems

As UAVs become more intelligent and connected, silicone sealants may be integrated with smart materials and systems. For instance, silicone sealants could be embedded with sensors to monitor their own condition, such as the degree of wear, temperature, or the presence of leaks. This data could then be used to trigger maintenance or repair actions in a timely manner, improving the overall reliability and safety of UAVs.

4.2.3 Sustainable and Environmentally Friendly Silicone Sealants

With the increasing focus on environmental sustainability, there will be a growing demand for silicone sealants that are more sustainable and environmentally friendly. This may involve the use of renewable raw materials in the production of silicone sealants, as well as the development of sealants with lower environmental impact during their manufacturing, use, and disposal. In the UAV industry, which is already striving to reduce its carbon footprint, the adoption of sustainable silicone sealants will be an important trend.

5. Conclusion

Silicone sealants play a vital role in the field of Unmanned Aerial Vehicles (UAVs). Their unique combination of properties, including temperature resistance, flexibility, dielectric and thermal insulation, UV and ozone resistance, adhesion, curing properties, and low outgassing, make them highly suitable for a wide range of applications within UAVs.