Research on the Application of Thermal Conductive Sealant in Solving the Heat Dissipation Problem of Circuit Boards

With the rapid development of electronic information technology, electronic devices are moving towards miniaturization, integration, and high performance. As the core component of electronic devices, circuit boards integrate an increasing number of electronic components with growing power density, leading to substantial heat generation during operation. If this heat is not dissipated timely and effectively, the temperature of components on the circuit board will rise, affecting their performance and service life, and even causing equipment failures. Therefore, solving the heat dissipation problem of circuit boards has become one of the key issues to be urgently addressed in the electronics industry. As a material with both thermal conductivity and sealing functions, thermal conductive sealant plays a crucial role in solving the heat dissipation problem of circuit boards.

Research on the Application of Thermal Conductive Sealant in Solving the Heat Dissipation Problem of Circuit Boards

Characteristics

- Good Thermal Conductivity: Thermal conductive sealants are filled with a large amount of thermal conductive fillers, giving them a high thermal conductivity coefficient to effectively transfer heat.

- Excellent Sealing Performance: They can seal circuit boards, preventing erosion by external environmental factors and improving the reliability and service life of circuit boards.

- Good Flexibility and Elasticity: The adhesive layer has certain flexibility and elasticity, adapting to the thermal expansion and mechanical vibration of circuit boards during operation to avoid component damage caused by stress concentration.

- High Temperature Resistance: Different types of thermal conductive sealants have different temperature resistance ranges, enabling their use in various temperature environments.

- Convenient Construction: They can be applied through brushing, spraying, dispensing, etc., with simple and convenient operations.

Analysis of Circuit Board Heat Dissipation Issues

(1) Hazards of Poor Heat Dissipation

- Reduced Component Performance: Electronic components on circuit boards may suffer performance degradation when operating at high temperatures. For example, the threshold voltage of semiconductor components decreases with increasing temperature, leading to increased leakage current and power consumption; the capacitance of capacitor components changes with temperature, affecting circuit stability.

- Shortened Component Lifespan: High temperatures accelerate the aging process of electronic components and shorten their service life. Studies show that for every 10°C increase in component temperature, its lifespan is halved.

- Equipment Failures: When heat accumulates to a certain level on the circuit board, equipment failures such as crashes, reboots, or burnout may occur, seriously affecting normal operation.

(2) Heat Dissipation Paths

The main heat dissipation paths for circuit boards include:

- Heat Conduction: Heat is conducted through components, wires, substrates, and other materials on the circuit board to the edges and surface of the board.

- Heat Convection: Heat on the circuit board surface is dissipated through the flow of air or other fluids, transferring heat to the surrounding environment.

- Heat Radiation: Heat on the circuit board surface is radiated outward in the form of electromagnetic waves, transferring heat to the surrounding environment.

(3) Factors Affecting Circuit Board Heat Dissipation

- Component Layout: Unreasonable layout of components on the circuit board can cause heat accumulation and affect heat dissipation. For example, concentrating high-power components in one area can raise the temperature of that area and form hotspots.

- Substrate Material: The thermal conductivity of circuit board substrate materials significantly impacts heat dissipation. Common substrate materials include FR-4, aluminum substrates, and ceramic substrates, among which aluminum and ceramic substrates have higher thermal conductivity coefficients and can effectively conduct heat.

- Heat Dissipation Structure: Poor design of the circuit board’s heat dissipation structure, such as the lack of heat sinks, heat pipes, or other heat dissipation devices, will affect heat dissipation efficiency.

- Ambient Temperature: Excessively high ambient temperature will reduce the heat dissipation capacity of the circuit board, causing the temperature of the circuit board to rise.

Application of Thermal Conductive Sealant in Solving Circuit Board Heat Dissipation Problems

(1) Thermal Conductivity Principle

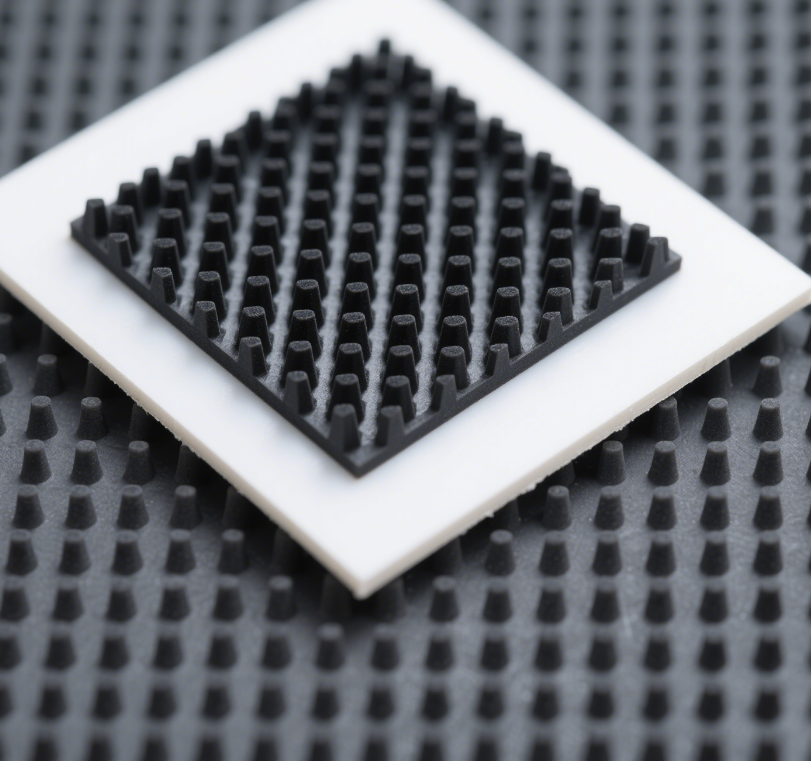

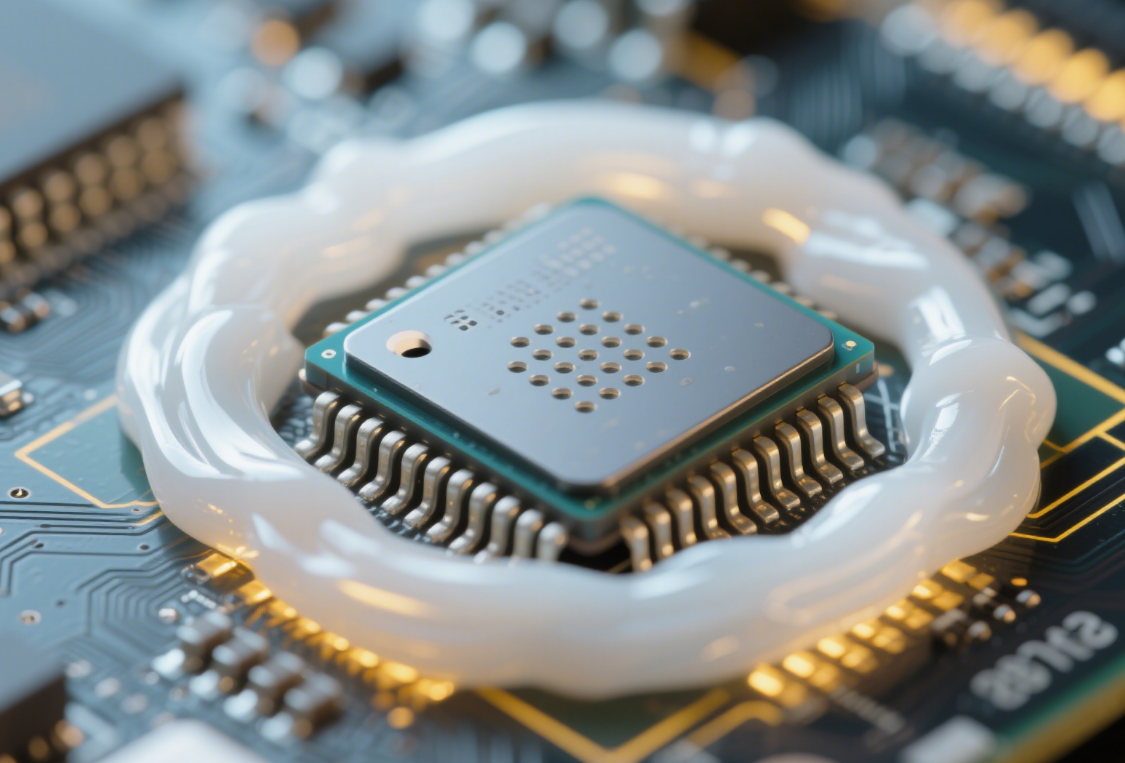

The thermal conductivity principle of thermal conductive sealants mainly involves forming thermal conductive pathways through thermal conductive fillers in the adhesive layer to transfer heat from heat-generating components to the circuit board substrate or heat dissipation devices. When there are gaps between heat-generating components and the circuit board substrate, thermal conductive sealants can fill these gaps, reduce air thermal resistance, and improve heat conduction efficiency. Additionally, thermal conductive sealants can transfer heat within the adhesive layer through their own thermal conductivity, achieving effective heat dissipation.

(2) Application Scenarios

- Bonding and Heat Dissipation Between Heat-Generating Components and Circuit Board Substrates: For high-power components such as power transistors and integrated circuits, firm bonding to the circuit board substrate and effective heat dissipation are required. Thermal conductive sealants can meet both needs, providing sufficient bonding strength while rapidly transferring heat generated by components to the substrate.

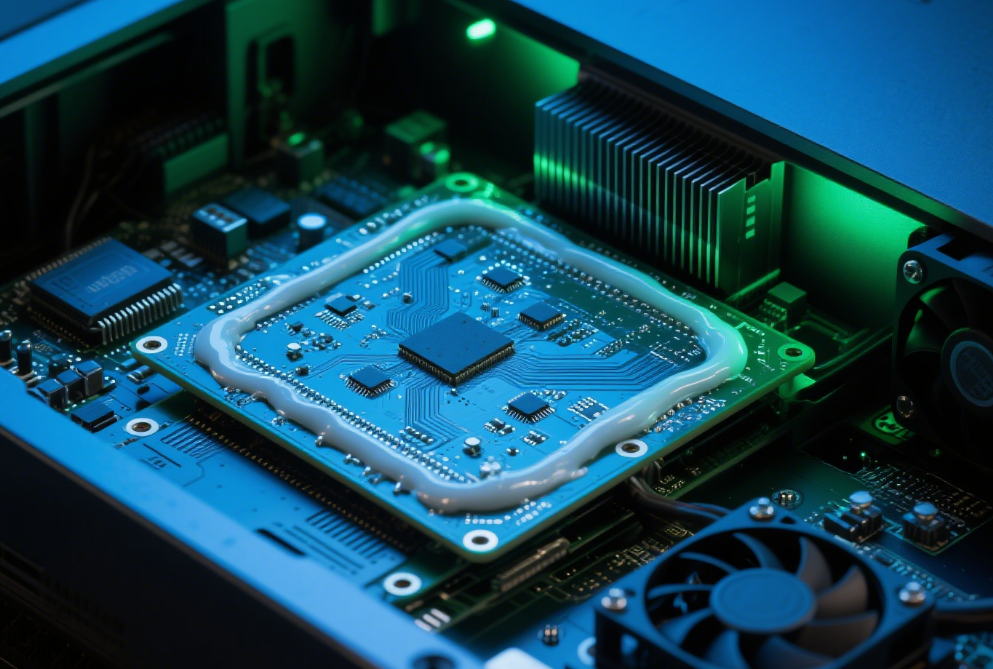

- Sealing and Heat Dissipation at Circuit Board Edges and Interfaces: Edges and interfaces of circuit boards are prone to erosion by external environmental factors and are also important pathways for heat dissipation. Thermal conductive sealants can seal these areas to prevent dust, moisture, etc., from entering the circuit board while improving heat dissipation efficiency.

- Connection and Heat Dissipation Between Heat Dissipation Devices and Circuit Boards: When heat dissipation devices such as heat sinks or heat pipes are installed on circuit boards, thermal conductive sealants can serve as connection materials to tightly bond the heat dissipation devices with the circuit board, reduce contact thermal resistance, and enhance heat dissipation performance.

(3) Selection Principles

- Thermal Conductivity: The thermal conductivity coefficient of thermal conductive sealants is one of the important selection criteria. A higher thermal conductivity coefficient indicates better heat transfer performance. The appropriate thermal conductivity coefficient should be selected based on the heat dissipation requirements of the circuit board and the power of heat-generating components.

- Temperature Resistance: Different circuit boards operate in different temperature environments, so thermal conductive sealants with corresponding temperature resistance ranges should be selected. For example, silicone thermal conductive sealants with high temperature resistance should be chosen for circuit boards operating in high-temperature environments, while polyurethane thermal conductive sealants with low temperature resistance are suitable for low-temperature environments.

- Bonding Strength: Thermal conductive sealants need to have a certain bonding strength to ensure a firm connection between heat-generating components and the circuit board substrate or heat dissipation devices. The appropriate bonding strength should be selected based on the weight of the components and the vibration conditions of the working environment.

- Flexibility and Elasticity: The flexibility and elasticity of the adhesive layer can adapt to the thermal expansion and mechanical vibration of the circuit board during operation to avoid component damage caused by stress concentration. Therefore, these properties should be considered when selecting thermal conductive sealants.

- Construction Process: The construction process of thermal conductive sealants should be simple and adaptable to different application methods such as brushing, spraying, and dispensing. Meanwhile, the curing time and conditions of the sealant should be considered to ensure construction efficiency and quality.

(4) Construction Process

- Surface Treatment: Before construction, the surfaces of the circuit board and components need to be cleaned to remove dust, oil, oxides, and other impurities, ensuring good adhesion between the thermal conductive sealant and the surfaces. Common cleaning methods include alcohol wiping and ultrasonic cleaning.

- Adhesive Application: The thermal conductive sealant is evenly applied to the bonding or sealing areas according to different construction methods. Attention should be paid to the thickness and uniformity of the adhesive layer to avoid air bubbles and voids. Generally, the adhesive layer thickness should be controlled between 0.1-0.3 mm to ensure good thermal conductivity and sealing performance.

- Curing: After applying the sealant, curing is performed according to the curing conditions of the thermal conductive sealant. Temperature, humidity, and time should be controlled during curing to ensure complete curing of the adhesive layer. Different types of thermal conductive sealants have different curing conditions; for example, silicone thermal conductive sealants typically require 24 hours of room-temperature curing or rapid curing at high temperatures.

Research Status and Development Trends of Thermal Conductive Sealants

Research on the Application of Thermal Conductive Sealant in Solving the Heat Dissipation Problem of Circuit Boards

(1) Research Status

Current research on thermal conductive sealants at home and abroad mainly focuses on the following aspects:

- Research on Thermal Conductive Fillers: To improve the thermal conductivity of thermal conductive sealants, researchers are continuously exploring new types of thermal conductive fillers such as nanoscale thermal conductive fillers and composite thermal conductive fillers. Nanoscale thermal conductive fillers have a large specific surface area and high thermal conductivity, significantly improving the thermal conductivity of the sealant at low filling amounts; composite thermal conductive fillers combine two or more types of thermal conductive fillers to leverage their respective advantages and enhance the comprehensive performance of the sealant.

- Research on Matrix Resins: To meet different application requirements, researchers are continuously developing new types of matrix resins such as high-temperature resistant, low-temperature resistant, solvent-resistant, and environmentally friendly matrix resins. Meanwhile, traditional matrix resins are being modified to improve their performance, such as enhancing the bonding strength and temperature resistance of silicone resins through copolymerization and grafting.

- Formula Optimization: The comprehensive performance of thermal conductive sealants, such as thermal conductivity, bonding strength, and temperature resistance, is improved by optimizing their formulations, such as adjusting the types and amounts of thermal conductive fillers, curing agents, and plasticizers.

(2) Development Trends

- Higher Thermal Conductivity: With the increasing power density of electronic devices, the requirements for the thermal conductivity of thermal conductive sealants are also rising. In the future, thermal conductive sealants will develop towards higher thermal conductivity, achieving higher thermal conductivity coefficients through new thermal conductive fillers and formula optimization to meet higher heat dissipation demands.

- Multifunctionality: In addition to thermal conductivity and sealing functions, thermal conductive sealants will develop towards multifunctionality, such as having insulation, moisture resistance, shock resistance, and flame retardancy to meet the needs of different application scenarios.

- Environmental Friendliness: With the growing awareness of environmental protection, the requirements for the environmental performance of thermal conductive sealants are also increasing. In the future, thermal conductive sealants will develop towards solvent-free, low volatile organic compounds (VOC), and degradable properties to reduce harm to the environment and human health.

- Intelligence: With the development of smart materials, thermal conductive sealants will also develop towards intelligence, such as having self-repairing, adaptive, and controllable thermal conductivity functions, which can automatically adjust their performance according to environmental temperature and heat dissipation needs to improve heat dissipation efficiency.

Conclusion

As a material with both thermal conductivity and sealing functions, thermal conductive sealant has important application value in solving the heat dissipation problem of circuit boards. It can effectively fill the gaps between heat-generating components and circuit board substrates, reduce air thermal resistance, improve heat conduction efficiency, and seal circuit boards to prevent erosion by external environmental factors. When selecting and using thermal conductive sealants, appropriate products should be chosen based on the heat dissipation requirements, working environment, component layout, etc., of the circuit board, and construction should be carried out strictly according to the construction process to ensure heat dissipation effect and reliability. With the continuous development of electronic technology, the performance requirements for thermal conductive sealants will become higher and higher. In the future, thermal conductive sealants will develop towards higher thermal conductivity, multifunctionality, environmental friendliness, and intelligence, providing better solutions for solving circuit board heat dissipation problems.