Application of Thermal Conductive Gaskets in MOS Products

1. Introduction

In the realm of modern electronics, Metal – Oxide – Semiconductor (MOS) products play a pivotal role. MOS devices, such as MOS transistors, are widely used in power electronics, integrated circuits, and various electronic systems due to their high switching speed, low on – resistance, and good thermal stability. However, during the operation of MOS products, significant heat is generated, which, if not effectively managed, can lead to a series of problems.

Thermal management is crucial for MOS products. High temperatures can cause a decrease in the performance of MOS devices, including an increase in on – resistance, a reduction in switching speed, and even device failure in severe cases. Therefore, efficient heat dissipation methods are essential to ensure the stable and reliable operation of MOS products. Thermal conductive gaskets have emerged as a key solution in this regard.

2. Thermal Conductive Gaskets: An Overview

2.1 Composition and Types

Thermal conductive gaskets are made from a variety of materials, with the most common ones being silicone – based, ceramic – based, and polymer – based.

Silicone – based thermal conductive gaskets: These are composed of silicone rubber as the matrix and are filled with thermal conductive fillers such as aluminum oxide (Al2O), boron nitride (BN), or carbon nanotubes. Silicone – based gaskets are known for their excellent flexibility, which allows them to conform well to uneven surfaces, reducing contact thermal resistance. For example, some silicone – based thermal conductive gaskets can achieve a thermal conductivity in the range of 1 – 6 W/(m·K).

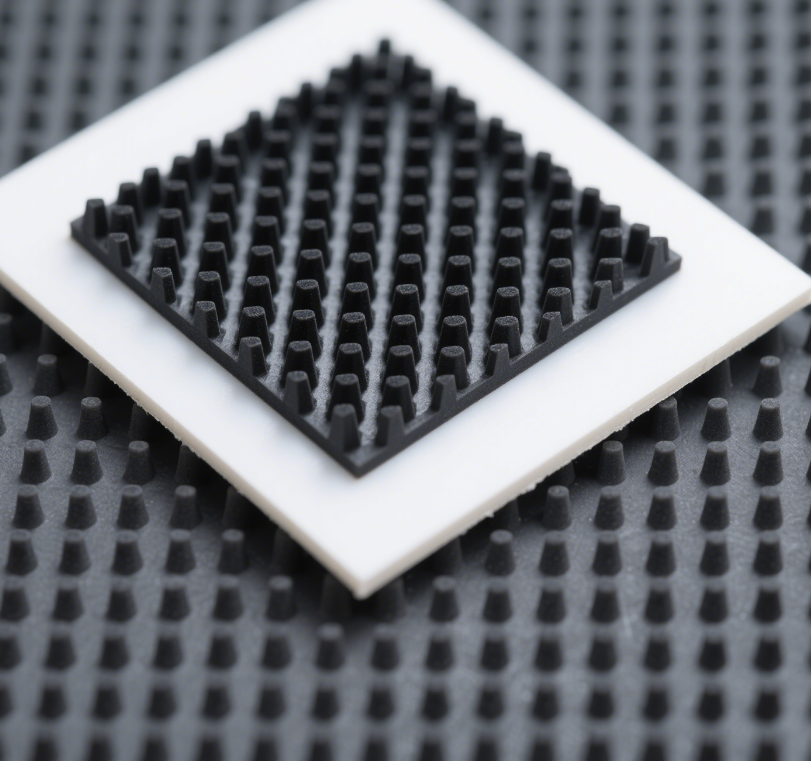

Ceramic – based thermal conductive gaskets: Mainly composed of high – purity alumina (usually with an alumina content of over 96%), ceramic gaskets have a pure white appearance and a hard texture. Their thermal conductivity can be as high as 20 – 30 W/(m·K), much higher than that of ordinary thermal conductive gaskets.

Thermal conductivity: This is the most critical property of thermal conductive gaskets. A higher thermal conductivity value indicates that the gasket can transfer heat more efficiently. As mentioned earlier, different types of gaskets have varying thermal conductivity ranges. In the context of MOS products, a higher thermal conductivity gasket is generally preferred to quickly transfer the heat generated by MOS devices to the heat sink.

Electrical insulation: MOS products often operate at high voltages, so the thermal conductive gasket must have good electrical insulation properties to prevent electrical short – circuits. For example, many thermal conductive gaskets have a high breakdown voltage.

Mechanical properties: Gaskets need to have appropriate mechanical strength and flexibility. Flexibility allows them to adapt to the irregularities of the surfaces of MOS devices and heat sinks, ensuring good contact. At the same time, they should have sufficient mechanical strength to withstand the pressure during the assembly process without being damaged. Some silicone – based gaskets have a Shore hardness in the range of 20 – 50 Shore A, providing a good balance between flexibility and strength.

Thermal expansion coefficient: It is important that the thermal expansion coefficient of the thermal conductive gasket is similar to that of the MOS device and the heat sink. This helps to maintain good contact between the components during temperature changes, preventing the formation of gaps due to differential thermal expansion, which could increase thermal resistance.

3. Heat Generation in MOS Products

3.1 Mechanisms of Heat Generation in MOS Devices

Joule heating: When current flows through the channel of a MOS transistor, there is resistance in the channel. According to Joule’s law (Q=I2Rt), where Q is the heat generated,Iis the current,Ris the resistance, and t

is the time, heat is generated due to the power dissipation in the channel resistance. The on – resistance (Ron) of MOS transistors is a key factor. As the current passing through the MOS device increases or the on – resistance becomes larger (which can be affected by factors such as temperature and device aging), more heat is generated.

Switching losses: During the switching process of MOS transistors (turn – on and turn – off), there are transient currents and voltages. The overlapping of current and voltage during these transitions leads to power dissipation, known as switching losses. High – speed switching applications, such as in power converters, are particularly prone to significant switching losses, which contribute to heat generation in MOS products.

3.2 Impact of Heat on MOS Product Performance

Performance degradation: High temperatures can cause the on – resistance of MOS transistors to increase. AsRon rises, more power is dissipated in the form of heat, creating a vicious cycle. This increase in on – resistance also leads to a reduction in the efficiency of power – handling circuits. For example, in a power MOSFET used in a DC – DC converter, a 10% increase in on – resistance due to high temperature can result in a significant decrease in the converter’s power conversion efficiency.

Reliability issues: Excessive heat can accelerate the aging of MOS devices. It can cause degradation of the gate oxide layer, which is crucial for the proper operation of MOS transistors. Over time, this can lead to a decrease in the breakdown voltage of the gate oxide, increasing the risk of device failure. In addition, high temperatures can cause mechanical stress in the device due to differential thermal expansion between different materials in the MOS package, potentially leading to cracks in the semiconductor material or solder joints.

4. Application of Thermal Conductive Gaskets in MOS Products

4.1 Mounting Configuration

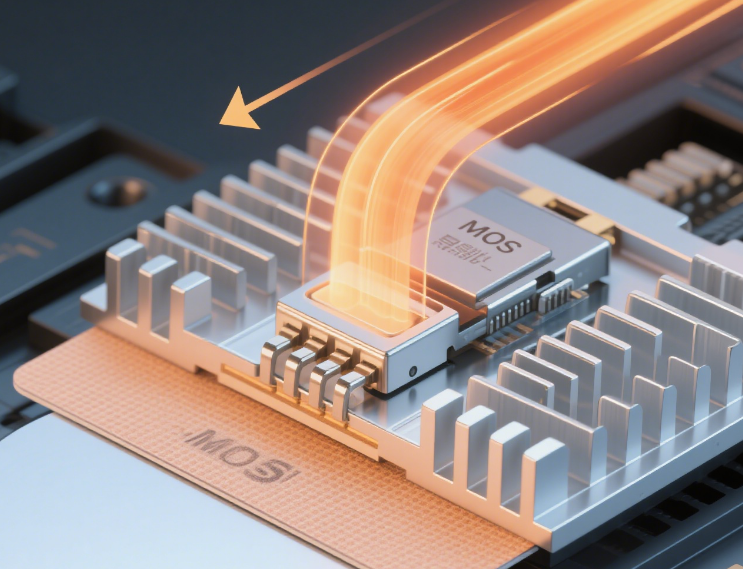

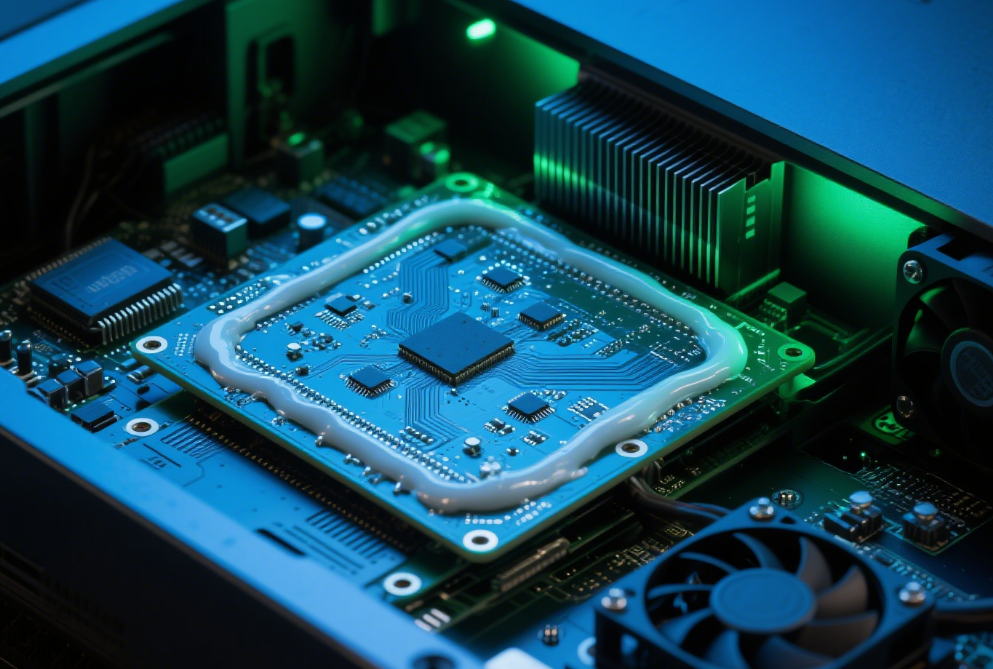

Direct contact between MOS device and heat sink: The thermal conductive gasket is placed between the back of the MOS device (usually the metal tab or the package surface) and the heat sink. For example, in a power module, the MOSFETs are mounted on a metal – based printed circuit board (PCB), and a heat sink is attached on the other side of the PCB. The thermal conductive gasket is inserted between the MOSFET package and the heat sink. When the heat sink is fastened to the PCB using screws or clips, the gasket is compressed, ensuring good thermal contact.

Using thermal conductive gaskets in multi – layer assemblies: In some complex MOS product designs, there may be multiple layers of components. For instance, in a high – power amplifier module, there may be a MOS device, a ceramic substrate for electrical insulation and mechanical support, and then a heat sink. The thermal conductive gasket is used at each thermal interface, i.e., between the MOS device and the ceramic substrate and between the ceramic substrate and the heat sink. This helps to transfer heat effectively through the different layers of the assembly.

4.2 Improving Thermal Performance

- Reducing contact thermal resistance: The main function of the thermal conductive gasket is to fill the microscopic gaps and irregularities between the MOS device and the heat sink. These gaps, if left unfilled, would be filled with air, which has a very low thermal conductivity (about 0.026 W/(m·K) at room temperature). By replacing the air with a thermal conductive gasket, the thermal resistance at the interface is significantly reduced. For example, a well – designed silicone – based thermal conductive gasket with a thermal conductivity of 3 W/(m·K) can reduce the contact thermal resistance by more than 80% compared to having an air – filled gap.

- Enhancing heat transfer efficiency: The high thermal conductivity of the gasket enables rapid heat transfer from the MOS device to the heat sink. In the case of a ceramic – based thermal conductive gasket with a thermal conductivity of 25 W/(m·K), it can quickly draw heat away from the MOS device. This helps to lower the operating temperature of the MOS device. A study showed that by using a high – performance thermal conductive gasket in a power MOSFET – based circuit, the operating temperature of the MOSFET could be reduced by 15 – 20 °C, which significantly improved the device’s performance and reliability.

- Preventing electrical short – circuits: As mentioned earlier, thermal conductive gaskets with good electrical insulation properties are essential in MOS products. In a power supply circuit where MOSFETs are used to control high – voltage DC power, the thermal conductive gasket acts as an electrical barrier between the high – voltage MOS device and the heat sink, which may be grounded or connected to other low – voltage components. This prevents electrical short – circuits that could otherwise damage the components or pose a safety risk.

- Meeting safety standards: In many industries, such as automotive and aerospace, there are strict safety regulations regarding electrical insulation in electronic devices. Thermal conductive gaskets that meet the required electrical insulation standards (such as a certain breakdown voltage and volume resistivity) ensure that MOS products can be used safely in these applications. For example, in automotive power electronics, the thermal conductive gaskets used in MOS – based motor controllers must meet the automotive industry’s safety standards for electrical insulation to prevent electrical malfunctions that could affect vehicle operation and safety.

- Problem description: In a DC – DC converter used in a portable electronic device, the power MOSFETs were generating excessive heat during operation. The original thermal management solution, which consisted of a simple heat sink and a low – quality thermal pad, was unable to effectively dissipate the heat. As a result, the converter’s efficiency dropped significantly, and the MOSFETs were at risk of overheating and failure.

- Solution implementation: A high – performance silicone – based thermal conductive gasket with a thermal conductivity of 4 W/(m·K) was selected. The gasket was placed between the power MOSFETs and the heat sink. The heat sink was redesigned to have a larger surface area and more fins to enhance heat dissipation.

- Results: After the implementation of the new thermal management solution, the operating temperature of the power MOSFETs decreased by 12 °C. The efficiency of the DC – DC converter increased from 85% to 90%, and the reliability of the converter was significantly improved. The product passed long – term reliability tests without any MOSFET failures.

- Problem description: In an electric vehicle’s motor control module, the MOSFETs used to drive the electric motor were experiencing high temperatures during high – power operation. The harsh operating environment of the vehicle, including vibrations and temperature fluctuations, made it challenging to maintain good thermal contact between the MOSFETs and the heat sink.

- Solution implementation: A ceramic – based thermal conductive gasket with excellent mechanical stability and a thermal conductivity of 22 W/(m·K) was chosen. The gasket was designed to have a special surface texture to improve its adhesion to the MOSFETs and the heat sink. In addition, a vibration – resistant mounting structure was developed to ensure that the gasket remained in place and maintained good thermal contact even under severe vibration conditions.

- Results: The use of the ceramic thermal conductive gasket and the new mounting structure reduced the MOSFET operating temperature by 20 °C. The motor control module’s performance was more stable, and the vehicle’s acceleration and energy efficiency improved. The module also passed the rigorous vibration and temperature cycling tests required for automotive applications, demonstrating its reliability in harsh environments.

- Research on new materials: Scientists are constantly exploring new materials for thermal conductive gaskets. For example, the use of graphene – based fillers in thermal conductive gaskets shows great potential. Graphene has an extremely high thermal conductivity (up to 5000 W/(m·K) in theory), and incorporating it into a gasket matrix could significantly enhance the gasket’s thermal performance. Some research groups are also looking at using new ceramic materials with even higher thermal conductivity and better mechanical properties.

- Nanocomposite materials: The development of nanocomposite thermal conductive gaskets is another trend. By dispersing nanoscale thermal conductive particles (such as nanosized boron nitride or aluminum oxide) in a polymer or silicone matrix, it is possible to achieve a better balance between thermal conductivity, mechanical properties, and flexibility. These nanocomposite gaskets may have improved thermal conductivity and better adhesion to surfaces, further reducing contact thermal resistance.

- Combination with phase – change materials: Phase – change materials (PCMs) can absorb and release large amounts of heat during phase transitions. Integrating thermal conductive gaskets with PCMs in MOS product thermal management systems could provide additional heat storage capacity. For example, a thermal conductive gasket could be combined with a PCM layer. When the MOS device generates a large amount of heat suddenly, the PCM would absorb the heat by melting, and then release it slowly when the temperature drops, helping to maintain a more stable operating temperature for the MOS device.

- Smart thermal management: With the development of sensor and control technologies, future thermal management systems for MOS products may incorporate smart features. Thermal conductive gaskets could be part of a system where sensors monitor the temperature of MOS devices in real – time. Based on the temperature data, the system could adjust the pressure applied to the gasket (for example, using a piezoelectric actuator) to optimize the thermal contact and heat transfer, ensuring the most efficient thermal management under different operating conditions.